A kind of polyurethane emulsion adhesive containing nano-cellulose whiskers and preparation method thereof

A nanocellulose, polyurethane emulsion technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of settling, weakening the performance of adhesives, etc. Convenience of use effect, effect of good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

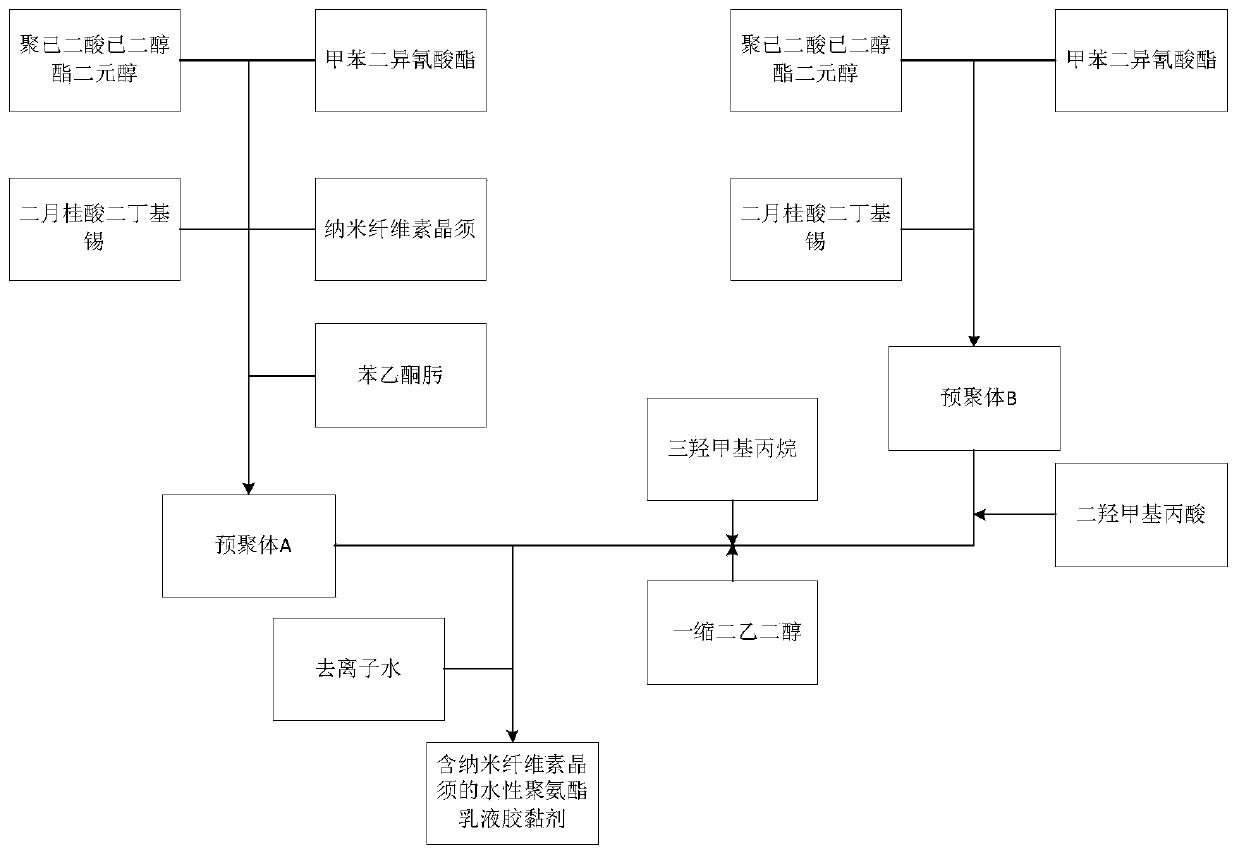

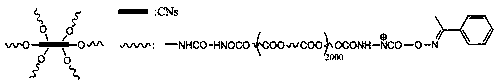

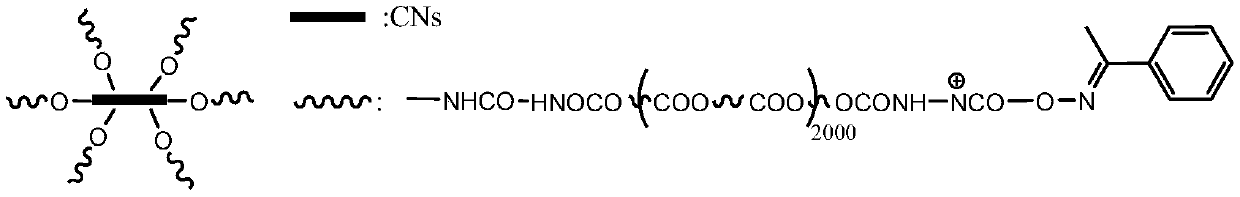

[0022] A preparation method of a polyurethane emulsion adhesive containing nanocellulose whiskers, comprising the following steps:

[0023] Step 1: Under the protection of nitrogen, add 1 mol of polyhexamethylene adipate diol and 2 mol of toluene diisocyanate, stir evenly, react at a temperature of 60-70°C for 2-3 hours, and add an aspect ratio of 200 , the specific surface area is 200m 2 / g, surface hydroxyl number is 30.0OH / nm 2 Add 2wt% dibutyltin dilaurate, continue to stir for 1-2h at a temperature of 80-90°C, then lower the temperature to 50°C, add 1mol of acetophenone oxime, and continue to stir for 2h to obtain the desired Polymer A, wherein, 2wt% is based on the sum of polyhexamethylene adipate diol and toluene diisocyanate.

[0024] Step 2: Under the protection of dry nitrogen, add 10 mol of polyhexamethylene adipate diol with a molecular weight of 4000 and 20 mol of toluene diisocyanate into the reactor, heat at 60°C, stir for 2 hours, and add 2 wt% of dilauric ac...

Embodiment 1

[0039]Step 1: Under the protection of nitrogen, add 1 mol of polyhexamethylene adipate diol and 2 mol of toluene diisocyanate, stir evenly, react at a temperature of 60°C for 3 hours, add 100 g of polyhexamethylene adipate diol with a specific surface area of 200 200m 2 / g, surface hydroxyl number is 30.0OH / nm 2 Add 2wt% of dibutyltin dilaurate, continue to stir for 1h at a temperature of 90°C, then lower the temperature to 50°C, add 1mol of acetophenone oxime, and continue to stir for 2h to obtain prepolymer A. Wherein, 2wt% is based on the sum of polyhexamethylene adipate diol and toluene diisocyanate;

[0040] Step 2: Add 10 mol of polyhexamethylene adipate diol with a molecular weight of 4000 and 20 mol of toluene diisocyanate into the reaction kettle, heat at 60° C., stir for 2 h, add 2 wt % of dibutyltin dilaurate, and continue stirring for 2 h. Obtain prepolymer B, wherein, 2wt% is based on the sum of polyhexamethylene adipate diol and toluene diisocyanate;

[0041...

Embodiment 2

[0045] Repeat the method of Example 1 according to the specified content of each component, but the temperature of the first section in step one is 70°C, and the stirring time is 2h; the temperature of the second section is 80°C, and the stirring time is 2h; the first section of step three The stage temperature is 60°C, the stirring time is 2h, and the viscosity of the system is 4000mPa·s. The properties of the adhesive are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com