Rubber powder and SBS modified compound modified asphalt and preparation method thereof

A technology of compound modified asphalt and modified asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of complex construction process, less dry process practice, and superior comprehensive performance, and achieves simple production process and high performance. And the effect of stability guarantee and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The method for preparing rubber powder / SBS composite modified asphalt of the present invention comprises the following steps:

[0045] (1) Eucommia gum grafted with maleic anhydride

[0046] The grafting of Eucommia gum is completed in a closed rubber mixer (referred to as internal mixer). First, the Eucommia gum is matured. The specific steps are to add Eucommia gum to the internal mixer, and then set the temperature of the internal mixer at 150±5°C, the rotation speed is set at 50±5rad / min, and the entire curing process is controlled within 1h~1.2h. In the second step, slowly add the cured eucommia gum into 50ml xylene, and heat the xylene solution to 120±5°C while adding, and at the same time keep stirring to gradually dissolve the eucommia gum in the xylene. After Eucommia gum is completely dissolved in xylene, gradually cool down to the reaction temperature (80±2°C), then add maleic anhydride according to the designed formula, stir continuously to promote the diss...

Embodiment 1

[0056] Example 1: Using three different quality grades of SBS modified asphalt to make rubber powder / SBS composite modified asphalt

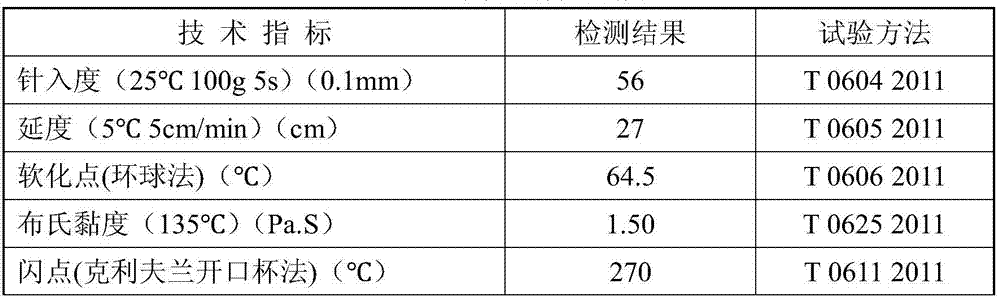

[0057] The performance test results of SBS modified asphalt A, B, C are shown in Table 4

[0058] Table 4 Test results of three kinds of SBS modified asphalt

[0059]

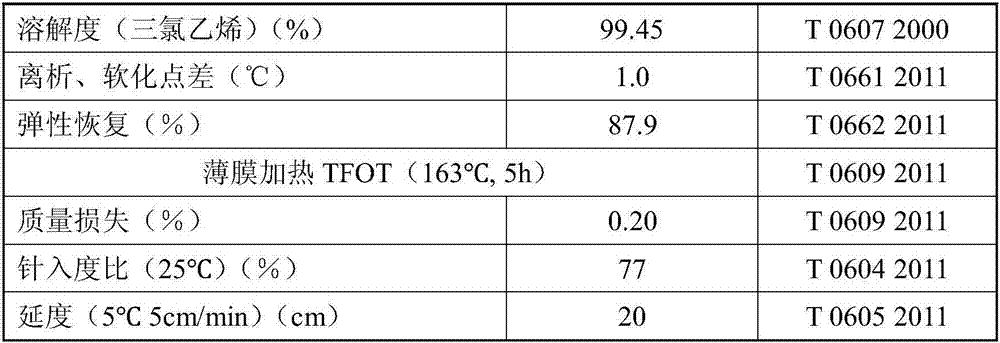

[0060] Composite modified asphalt was produced according to the technical scheme mentioned above, and its performance test was carried out. The test results are shown in Table 5.

[0061] Table 5 Test results of three kinds of rubber powder / SBS composite modified asphalt

[0062]

[0063] Comparing Table 4 and Table 5, it can be seen that SBS modified asphalt with different properties is used to make rubber powder / SBS composite modified asphalt. promote. Can be applied to engineering practice

Embodiment 2

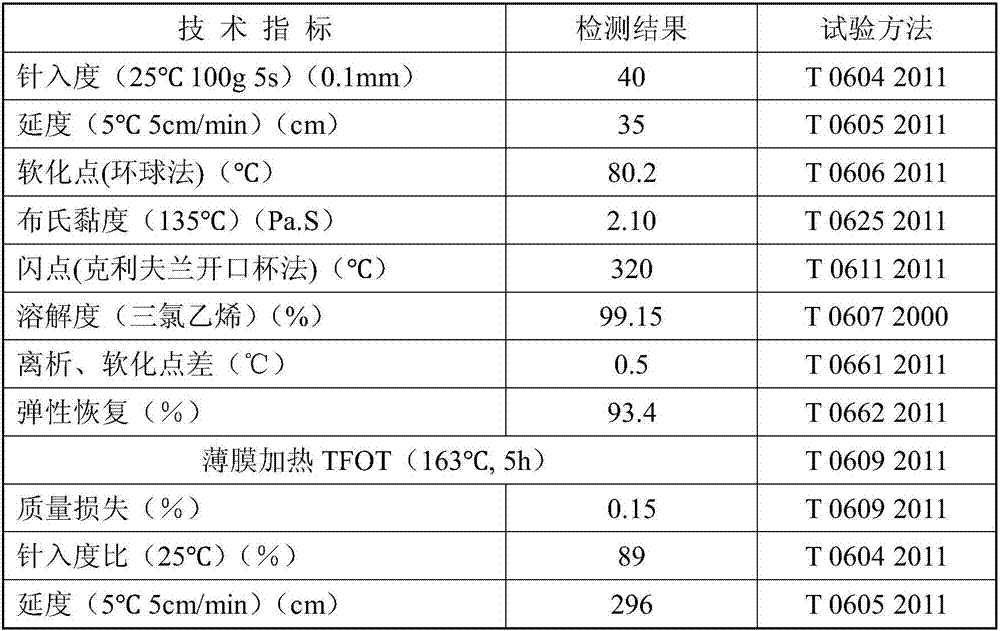

[0064] Example 2: Using rubber powder / SBS composite modified asphalt as a binder to produce asphalt mixture, the used gradation is AC-13C, according to the test specified in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20 2011) Method, perform performance test, and compare with SMA. The results are shown in Table 6.

[0065] Table 6 Performance test results of asphalt mixture

[0066] Test items

[0067] It can be seen from Table 6 that the performance of rubber powder / SBS composite modified asphalt mixture is relatively close to that of SMA, and it is better than SMA in terms of high temperature anti-rutting, which shows that the composite modified asphalt road performance of the present invention is also very excellent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com