A semi-short-path nitrification reactor for kitchen anaerobic wastewater and a method for starting the semi-short-path nitrification

A technology for semi-short-range nitrification and kitchen wastewater, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water treatment parameter control, etc. Stable, saving carbon and energy, the effect of high nitrosation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

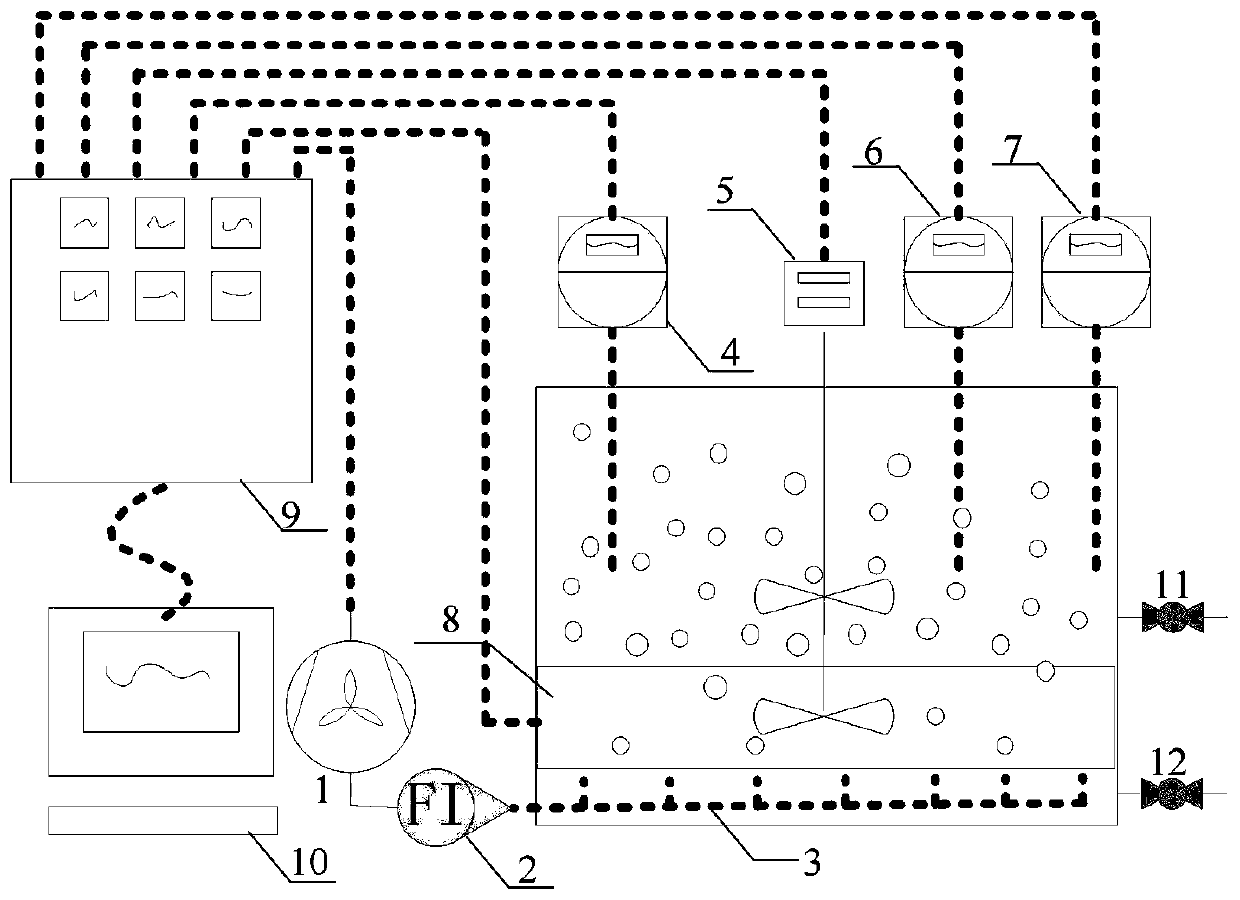

[0034] The semi-short-range nitrification reactor is a stainless steel cylindrical structure, design parameters: bottom diameter (φ) × height (H) = 30cm × 30 cm, effective volume is 15L, and the side wall at the bottom of the reactor is equipped with an air inlet. The port is connected to the air pump 1 through a pipeline, and the other end of the air pump 1 is connected to the PLC control system 9; a gas flow meter 2 is set between the air inlet and the air pump 1; an aeration device 3 is set at the bottom of the reactor, and the air is supplied by the air pump 1 The gas flow meter 2 reaches the aeration device 3 installed at the bottom of the reactor, and the air pump 1 is used for aeration during the aeration period to provide dissolved oxygen for the inside of the system. The aeration device 3 is composed of 16 microporous aeration heads, which are evenly distributed from the central position of the reactor bottom to the surroundings through the ventilation pipe, and each a...

Embodiment 2

[0037] Inoculate the sludge into the semi-short-path nitrification reactor, and the inoculated sludge comes from the kitchen wastewater treatment plant A 3 / O 3 The aerobic tank sludge in the process, the sludge concentration is 6g / L, the inoculated sludge is strongly aerated in the reactor for 1d, the DO is controlled at 6-8mg / L, and the temperature is controlled at 30±1°C, so that the sludge has Full nitrification capacity.

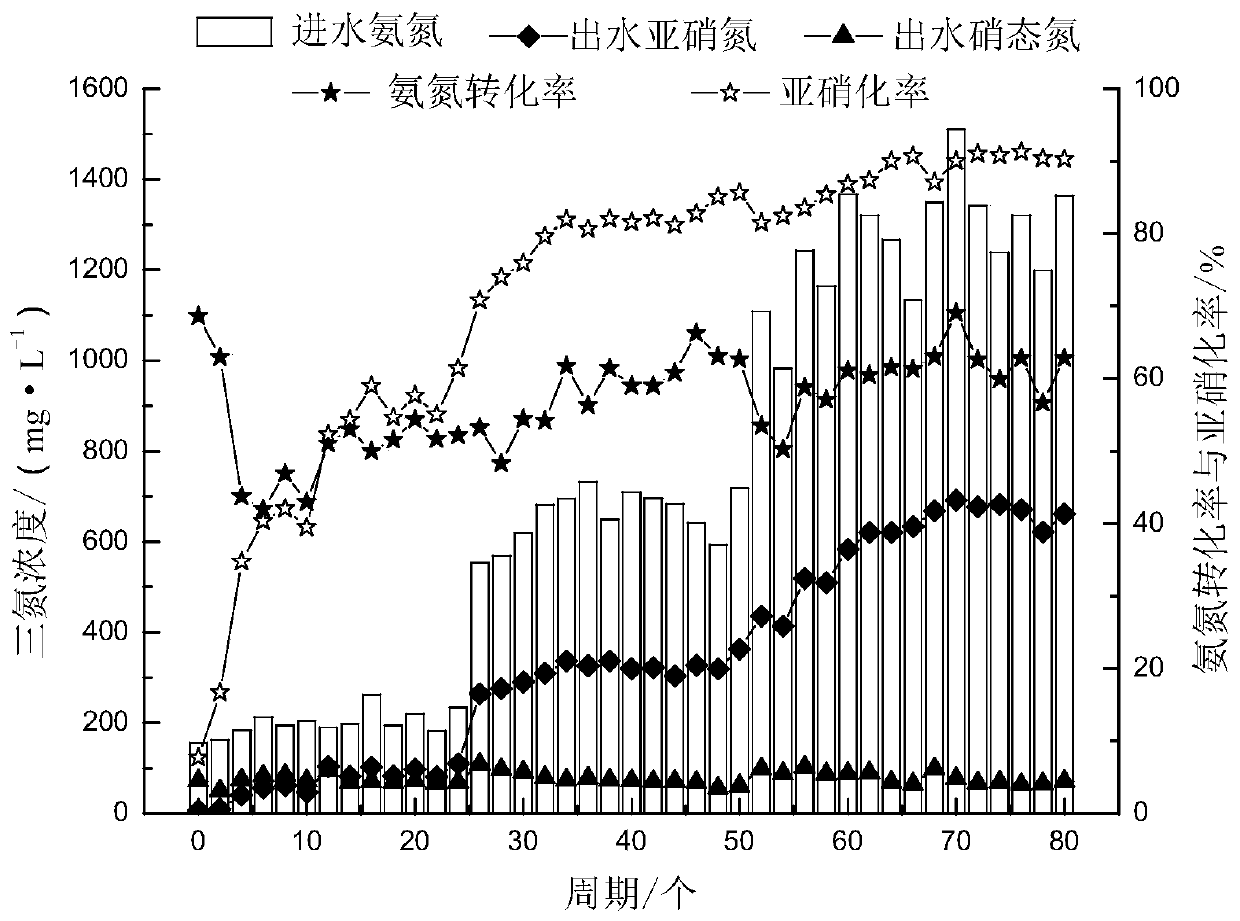

[0038] The SBR operation mode is adopted, and the operation cycle includes water inflow for 10 minutes, continuous stirring and aeration for 8 hours, static precipitation for 2 hours, and drainage for 10 minutes. Run two cycles per day, each with 5L of water inflow and discharge. At the beginning of the cycle, 5L of influent water enters the reactor through a peristaltic pump, and at the same time, a precision stirring device is started to fully mix the mud and water. After the water inflow stage is completed, the air pump is turned on to aerate the r...

Embodiment 3

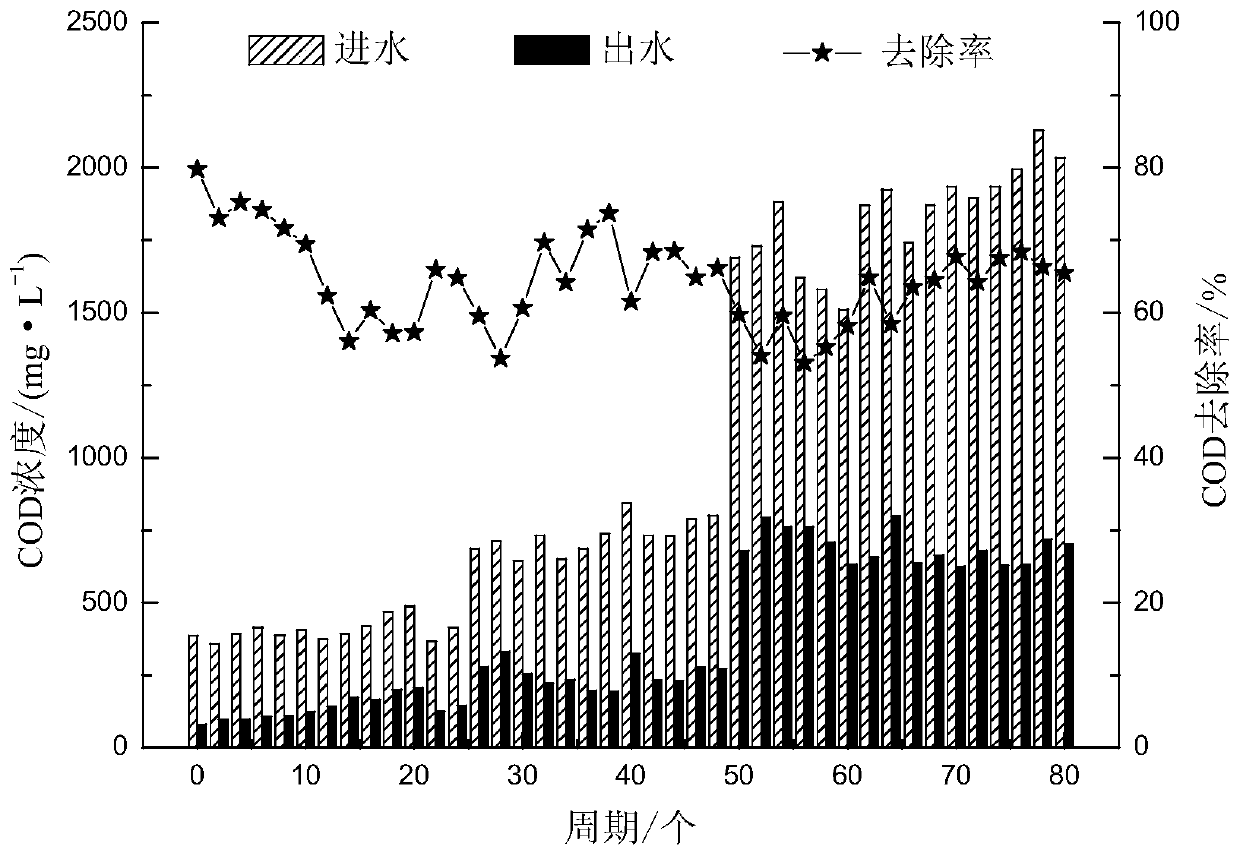

[0043] The specific implementation method is the same as in Example 2, the difference is that different DO concentrations are controlled, and the influence of DO concentration on the reaction system is studied, and stable NO is successfully achieved in the SBR process. 2 - After -N accumulation, the DO concentration in the system was changed to investigate the effect of different DO concentrations on the operating efficiency of the nitrosation system. At this stage, the average concentration of COD in the water is 1874mg / L, NH 4 + -N, NO 2 - -N, NO 3 - - The average value of N is 1231mg / L, 2mg / L and 29mg / L, and 6 different DO concentration stages are set.

[0044] When the DO concentration is lower than 0.5mg / L, the COD removal rate of the system is low, the subdigestibility is low, and the molar ratio of nitrite nitrogen to ammonia nitrogen in the effluent is 1:2 to 1:4; the aeration time increases, and the same amount of NH is oxidized 4 + The -N rate is slower and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com