High-performance magnesium-lithium alloy welding wire and preparation method and application thereof

A magnesium-lithium alloy, high-performance technology, applied in the field of high-performance magnesium-lithium alloy welding wire and its preparation, can solve the problems of many pores in the weld seam, large tendency of welding hot cracks, and low welding strength, and achieve stable and continuous welding performance Production, guaranteed excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

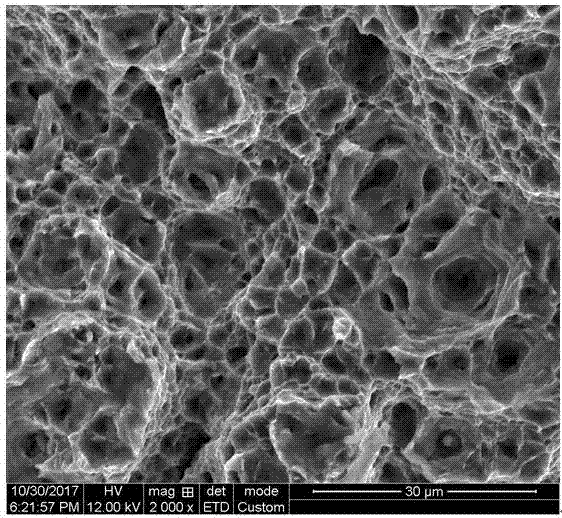

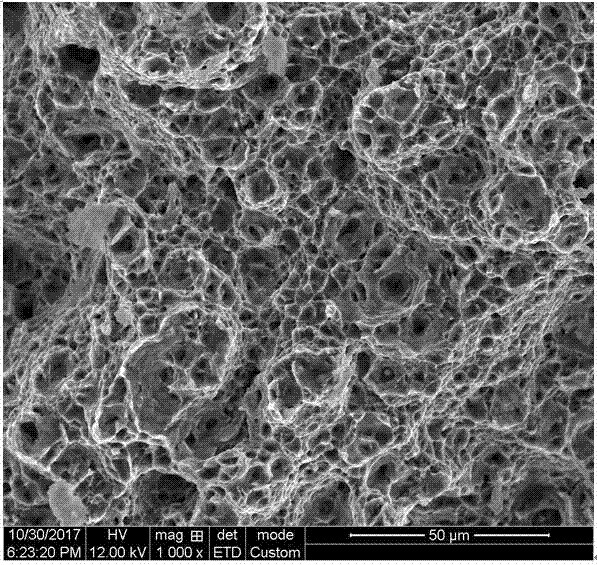

Image

Examples

Embodiment 1

[0026] A high-performance magnesium-lithium alloy welding wire, containing the following components by mass percentage: 87% by mass of Mg, and 0.58% by mass of impurities; the impurities are: 3.0% by mass of Al , the mass percentage of Zn is 0.002%, the mass percentage of Ca is 0.001%, the mass percentage of Cu is 0.001%, the mass percentage of Ag is 0.002%, and the balance is Li.

[0027] The preparation method of this high-performance magnesium-lithium alloy welding wire specifically includes the following steps:

[0028] Step (1): Vacuum melting the above-mentioned specific components at a melting temperature of 700°C, and homogenizing annealing treatment on the melted ingot.

[0029] Step (2): Extrude the smelted ingot into a rod with a diameter of 9.5 mm through a die.

[0030] Step (3): Pass the φ9.5mm magnesium-lithium alloy rod through the water tank wire drawing machine from φ9.5mm-φ7.85mm-φ6.25mm-φ5.5mm-φ4.25mm-φ3.75mm-φ2.35mm-φ1. 98mm is prepared as a wire, and af...

Embodiment 2

[0038] A high-performance magnesium-lithium alloy welding wire, containing the following components by mass percentage: 88% by mass of Mg, and 0.43% by mass of impurities; the impurities are: 4.0% by mass of Al , the mass percentage content of Zn is 0.003%, the mass percentage content of Ca is 0.002%, the mass percentage content of Cu is 0.002%, the mass percentage content of Ag is 0.004%, and the balance is Li.

[0039] The preparation method of this high-performance magnesium-lithium alloy welding wire specifically includes the following steps:

[0040] Step (1): Vacuum melting the above-mentioned specific components at a melting temperature of 720°C, and homogenizing annealing treatment on the melted ingot.

[0041] Step (2): Extrude the smelted ingot into a φ9.5mm rod through a die.

[0042] Step (3): Pass the φ9.5mm magnesium-lithium alloy rod through the water tank wire drawing machine from φ9.5mm-φ7.85mm-φ6.25mm-φ5.5mm-φ4.25mm-φ3.75mm-φ2.35mm-φ1. 98mm is prepared into...

Embodiment 3

[0050] A high-performance magnesium-lithium alloy welding wire, containing the following components by mass percentage: the mass percentage of Mg is 89%, the mass percentage of impurities is 0.63%; the impurities are: the mass percentage of Al is 5.0%, The mass percentage content of Zn is 0.005%, the mass percentage content of Ca is 0.004%, the mass percentage content of Cu is 0.003%, the mass percentage content of Ag is 0.006%, and the balance is Li.

[0051] The preparation method of this high-performance magnesium-lithium alloy welding wire specifically includes the following steps:

[0052] Step (1): Vacuum melting the magnesium-lithium alloy with specific composition.

[0053] Step (2): Extrude the smelted ingot into a φ9.5mm rod through a die.

[0054] Step (3): Pass the φ9.5mm magnesium-lithium alloy rod through the water tank wire drawing machine from φ9.5mm-φ7.85mm-φ6.25mm-φ5.5mm-φ4.25mm-φ3.75mm-φ2.35mm-φ1. 98mm is prepared into wire material, which has been wound t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com