Frictional diffusion welding method for aluminum target assembly

A technology of diffusion welding and friction welding, which is applied in welding equipment, non-electric welding equipment, welding/welding/cutting items, etc., can solve the problem of inability to meet long-term stable production and use of aluminum target components, difficulty in forming atomic-scale bonding, target materials, etc. Solve problems such as low welding strength of components to achieve the effect of less defects, low cost and dense weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The friction diffusion welding method of the aluminum target assembly of the present embodiment comprises the following steps:

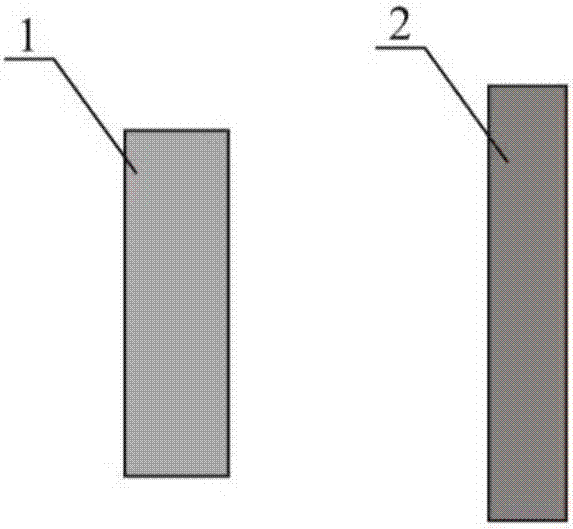

[0038] Step 1: Prepare the aluminum target 1 and the aluminum back plate 2. The aluminum target 1 is pure aluminum with a purity of not less than 99.999%, and its shape is a cylinder; the material of the aluminum back plate 2 is hardness, high strength, conductivity, An aluminum alloy with good thermal conductivity, such as 6061 aluminum alloy, is in the shape of a flat cylinder with a diameter slightly larger than the aluminum target, and its thickness must ensure sufficient support strength. The shapes of the aluminum target 1 and the aluminum back plate 2 are as follows: figure 1 shown;

[0039] The surface to be welded of the aluminum target 1 and the aluminum back plate 2 is mechanically polished, and the obtained surface roughness Ra of the surface to be welded is not higher than 1.6.

Embodiment 2

[0046] In this embodiment, except for the aluminum back plate selected in step 1, and the pressure and temperature applied in step 2 and step 3 are different, the rest of the process is the same as that of embodiment 1.

[0047] Step 1: Prepare the aluminum target 1 and the aluminum back plate 2. The aluminum target 1 is pure aluminum with a purity of not less than 99.999%, and its shape is a cylinder; the material of the aluminum back plate 2 is hardness, high strength, conductivity, For aluminum alloys with good thermal conductivity, such as 5083 aluminum alloy, its thickness must be able to ensure sufficient support strength. The shapes of the aluminum target 1 and the aluminum back plate 2 are as follows: figure 1 shown.

[0048]The surface to be welded of the aluminum target 1 and the aluminum back plate 2 is mechanically polished, and the obtained surface roughness Ra of the surface to be welded is not higher than 1.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com