Belt oil wheel device capable of adjusting meshing automatically

A technology with automatic adjustment and oil tanker, which is applied in the direction of transmission parts, belt/chain/gear, gear lubrication/cooling, etc. It can solve the problems of oil pipe drop lubrication effect, large manufacturing error, weld cracking, etc., and achieve good performance Stable lubricating effect, low manufacturing cost, eliminate destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

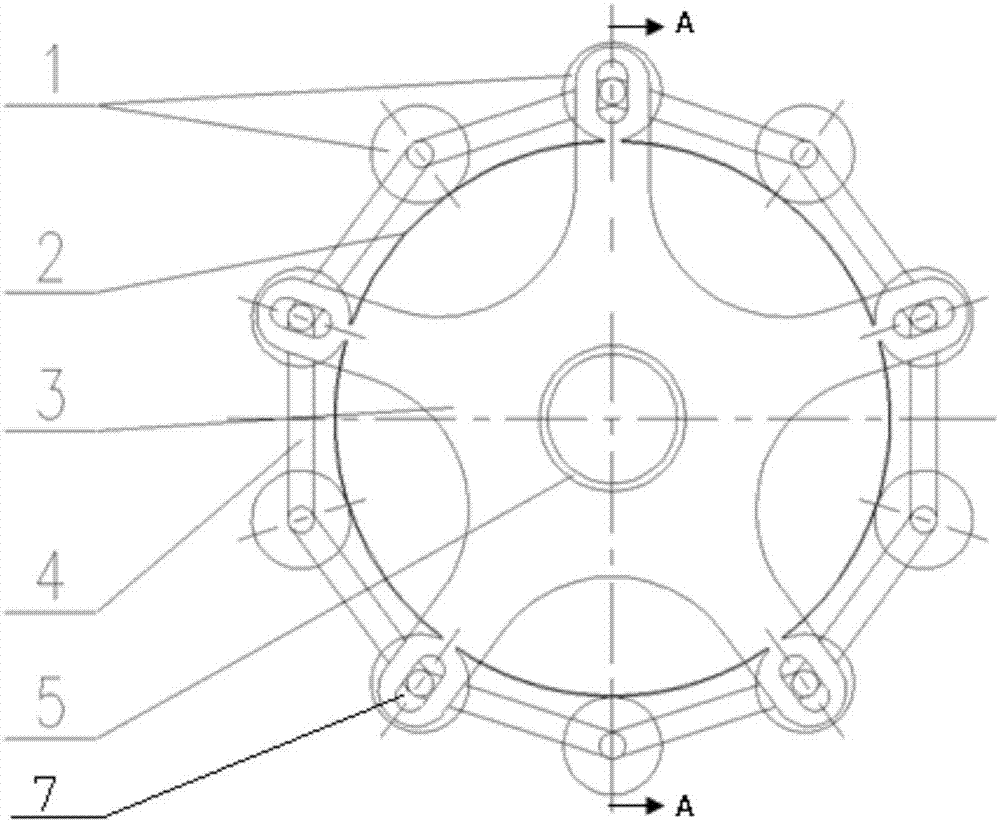

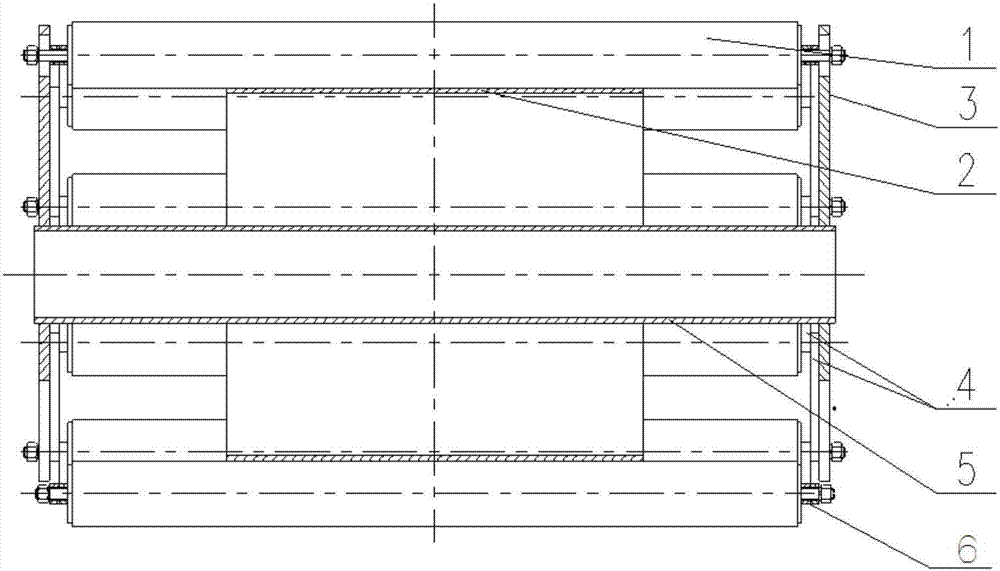

[0018] refer to figure 1 and figure 2 , the preferred embodiment of the present invention provides a kind of automatic adjustment meshing belt oil tanker device, comprises axle 5, several oil pipes 1 and hub plate 3, also comprises elastic tube 2, and described hub plate 3 is fixed on the two ends of wheel axle 5, and described The two ends of the oil pipe 1 are connected to the hub plate 3, and the oil pipes 1 are connected through the chain plate 4. The elastic tube 2 is arranged between the hub plates 3 and fixed at the middle position of the wheel shaft 5. All the oil pipes 1 and the elastic tube 2 are attached to the outer surface.

[0019] In order to facilitate the design and manufacture, the elastic tube is made of commonly used oil-resistant rubber material with an appropriate elastic coefficient.

[0020] In order to ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com