Multiblock furanyl polyether ester shape memory material and preparation method thereof

A technology of furyl polyether ester and memory materials, which is applied in the field of polymer materials and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

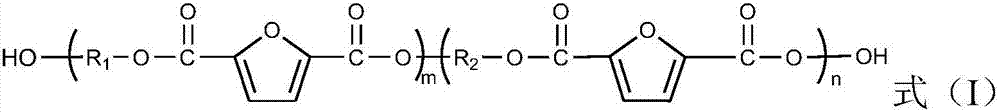

[0029] The present invention also provides a preparation method of a multi-block furyl polyether ester shape memory material, comprising:

[0030] Step 1: Under the action of a catalyst, transesterify dimethyl 2,5-furandicarboxylate, diR1 2,5-furandicarboxylate and diR2 2,5-furandicarboxylate to obtain a prepolymer thing;

[0031] Step 2: The prepolymer obtained in Step 1 is subjected to polycondensation reaction to obtain a multi-block furyl polyether ester shape memory material.

[0032] According to the present invention, the reaction temperature in step 1 is preferably 60-200°C, more preferably 170-200°C; the reaction time is preferably 1-3 hours, more preferably 2-3 hours; the reaction pressure is preferably 0.1MPa-0.5MPa , more preferably 0.15MPa-0.2MPa.

[0033] According to the present invention, the catalyst in the first step is a tin-based or titanium-based catalyst. The tin catalyst is preferably stannous oxide, stannous octoate, stannous chloride, stannous bromi...

Embodiment 1

[0042](1) Under the effect of stannous oxalate, 2,5-dimethyl furandicarboxylate, 2,5-diethylene glycol furandicarboxylate and 2,5-diethylene glycol furandicarboxylate ( Polyethylene glycol number average molecular weight 6000) was added to the reaction flask, dimethyl 2,5-furandicarboxylate, diethylene glycol 2,5-furandicarboxylate and diethylene glycol 2,5-furandicarboxylate The mass ratio of alcohol ester is 1:20:30, and stannous oxalate accounts for 0.3% of the total diester mass percentage. Under the protection of nitrogen, the reaction is stirred at 180°C for 3 hours and the pressure is 0.15MPa to form a prepolymer.

[0043] (2) Vacuumize the above prepolymer to 80 Pa, stir and react at 235° C. for 8 hours to obtain a multi-block furyl polyether ester shape memory material. The structural formula is as follows:

[0044]

[0045] The H NMR spectrum of the multi-block furyl polyether ester shape memory material prepared in Example 1 is as follows figure 1 shown.

[00...

Embodiment 2

[0053] (1) Under the effect of stannous oxalate, 2,5-dimethyl furandicarboxylate, 2,5-dihexyl glycol furandicarboxylate and 2,5-diethylene glycol furandicarboxylate ( Polyethylene glycol number average molecular weight 20000) is added in the reaction bottle, 2,5-furandicarboxylic acid dimethyl ester, 2,5-furandicarboxylic acid dihexanediol ester and 2,5-furandicarboxylic acid diethylene glycol The mass ratio of alcohol ester is 1:30:30, and stannous oxalate accounts for 0.1% of the total diester mass percentage. Under the protection of nitrogen, stir and react at 200°C for 1 hour, and the pressure is 0.2MPa to form a prepolymer.

[0054] (2) Vacuumize the above-mentioned prepolymer to 70 Pa, stir and react at 220° C. for 5 hours, and obtain a multi-block furyl polyether ester shape memory material. The structural formula is as follows:

[0055]

[0056] The H NMR spectrum of the multi-block furyl polyether ester shape memory material prepared in Example 2 is as follows f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com