Crack-resistant reinforced concrete

A reinforced concrete technology, applied in the field of building materials, can solve the problems of unsatisfactory concrete crack resistance, achieve obvious crack resistance, weaken corrosion, improve tensile strength and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (do not add fiber and also do not add the concrete that three-dimensional metal structure forms)

[0029] Take 1465 parts of aggregate, 185 parts of ordinary portland cement, 80 parts of fly ash, 50 parts of mineral powder, 25 parts of silica fume, 5 parts of cement mortar defoamer, 10 parts of coupling agent, stir and mix to form a fiber-free Three-dimensional metal structure of concrete.

Embodiment 2

[0030] Embodiment 2 (adding the concrete that fiber forms)

[0031] Take 245 parts of alkali-resistant glass fiber, 1465 parts of aggregate, 185 parts of ordinary Portland cement, 80 parts of fly ash, 50 parts of mineral powder, 25 parts of silica fume, 5 parts of cement mortar defoamer, and 10 parts of coupling agent , stirring and mixing to form fiber concrete.

Embodiment 3

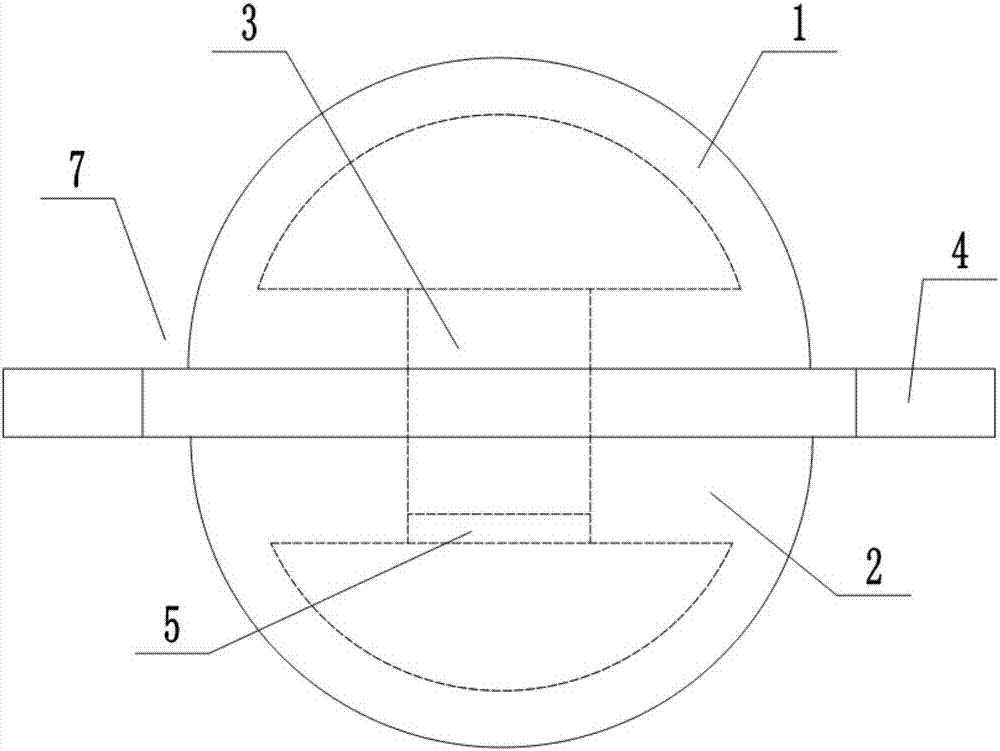

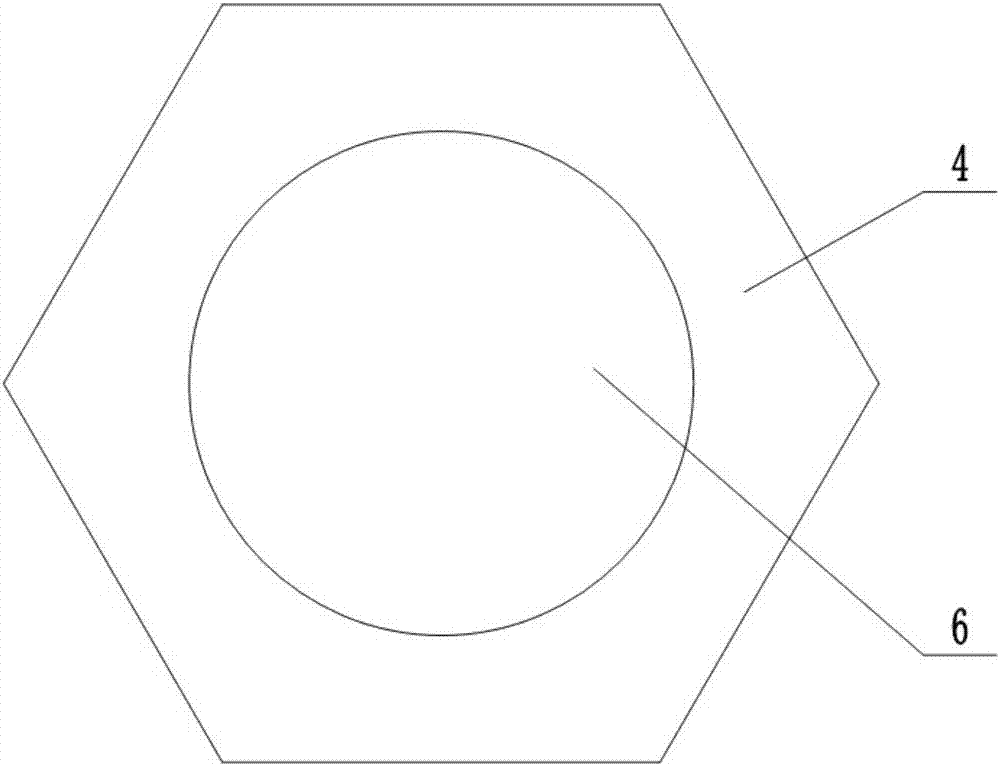

[0032] Embodiment 3 (adding the crack resistance reinforced concrete formed by three-dimensional metal structure)

[0033] Take 245 parts of three-dimensional metal structure, 1465 parts of aggregate, 185 parts of ordinary portland cement, 80 parts of fly ash, 50 parts of mineral powder, 25 parts of silica fume, 5 parts of cement mortar defoamer, 10 parts of coupling agent, Agitation mixes to form crack-resistant reinforced concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com