Phosphorus-containing and rare earth-containing Y molecular sieve and preparation method thereof

A molecular sieve and rare earth technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, molecular sieves and alkali exchange compounds, etc., can solve the problem of low micropore volume, reduce olefin content, increase heavy oil conversion rate, and reduce coke yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

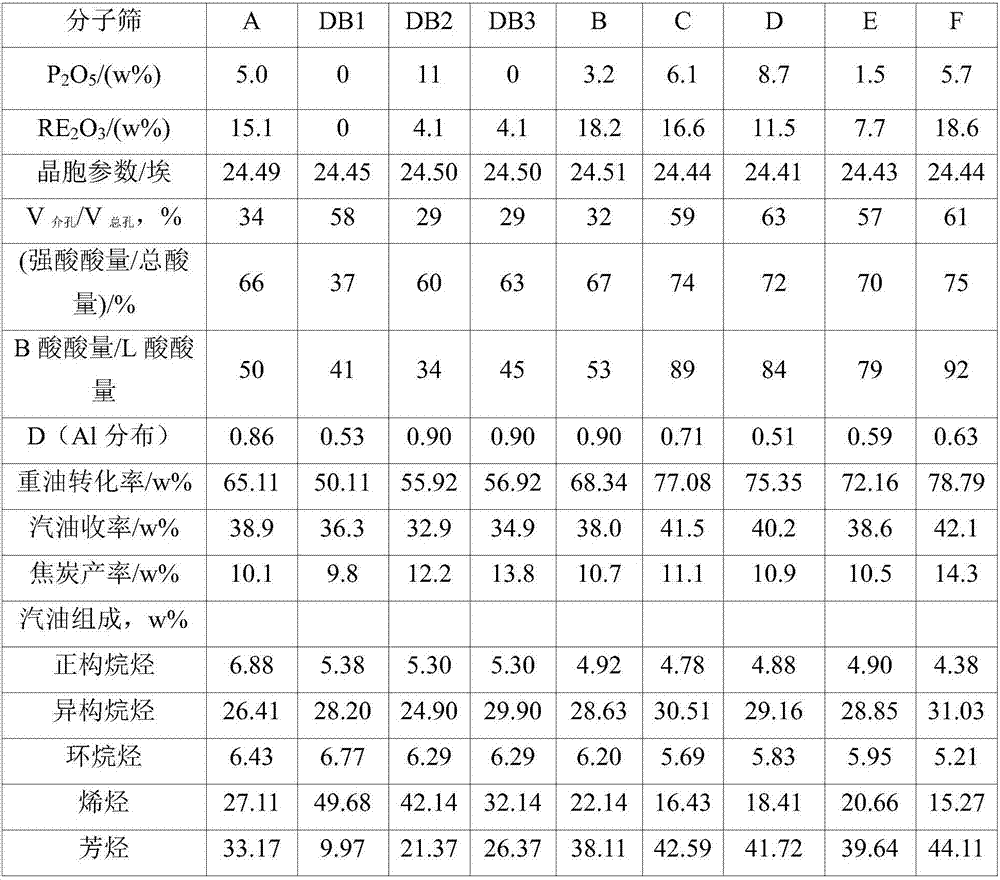

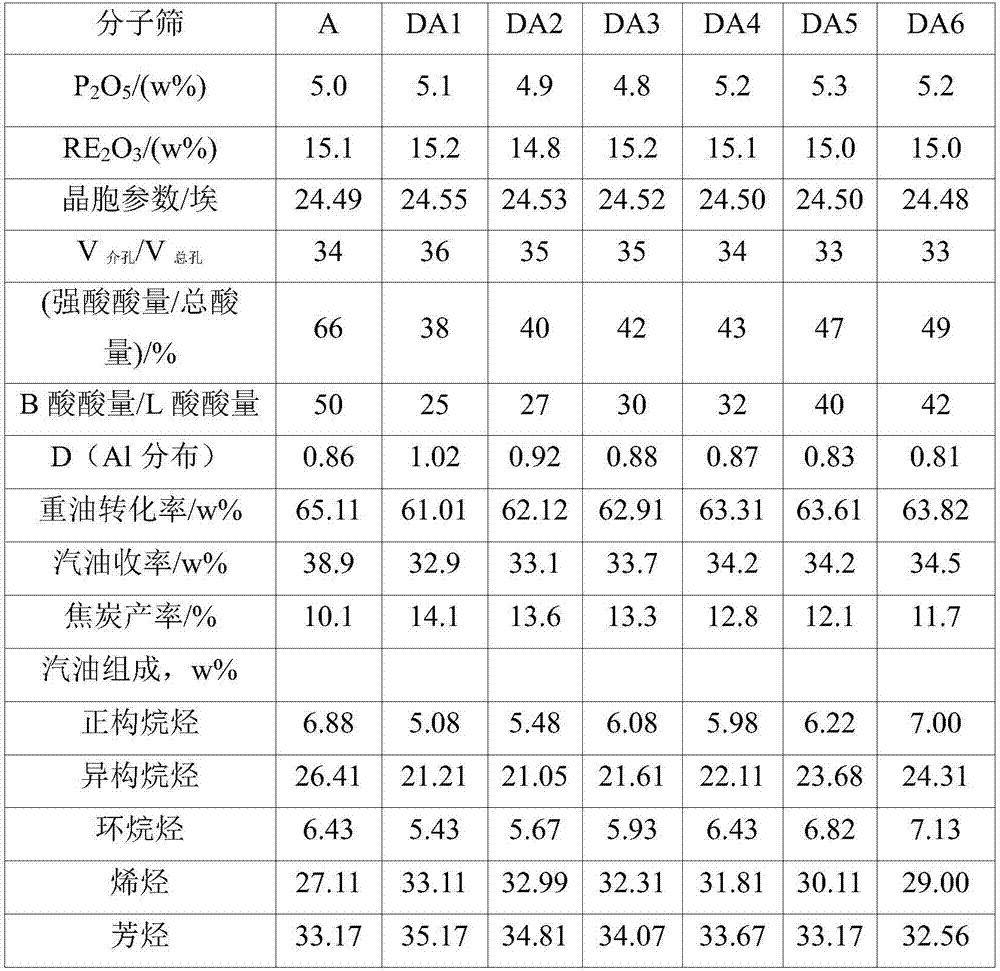

Examples

preparation example Construction

[0039] The present disclosure also provides a method for preparing the phosphorus- and rare-earth-containing Y molecular sieve provided by the present disclosure. The preparation method includes: a. NaY molecular sieve is subjected to ammonium exchange treatment, and after filtering and washing, ammonium exchange Molecular sieve; wherein, based on the dry weight of the ammonium exchanged molecular sieve based on sodium oxide, the sodium oxide content of the ammonium exchanged molecular sieve is less than 5% by weight; Carry out the first hydrothermal calcination treatment in step b to obtain the hydrobaked molecular sieve; c, the hydrobaked molecular sieve obtained in step b is subjected to the first dealumination treatment in the acid solution composed of organic acid and inorganic acid, and after filtering and washing, Obtain the first dealuminated molecular sieve; d, carry out alkali treatment on the first dealuminated molecular sieve obtained in step c in an inorganic alkal...

Embodiment 1

[0066] Y molecular sieve (produced by Catalyst Qilu Branch, unit cell parameter 24.63 angstroms) and NH 4 Cl and distilled water were mixed and beaten evenly at a ratio of 1:1:10, ammonium was exchanged at 70°C for 1 hour, the sample was filtered, washed, and dried, and the sodium content of the molecular sieve was determined to be less than 5% by weight. The above-mentioned molecular sieves were calcined at 600° C. and 100% steam for 2 hours. Take 100 g (dry basis mass) of the roasted molecular sieve and add water to prepare a molecular sieve slurry with a solid content of 10% by weight, add 3 g of citric acid during stirring, and then add 400 g of hydrochloric acid (mass fraction 10%) for 30 minutes; heat up to a constant temperature of 75 ° C Stir for 1 h, filter and wash until the filtrate is neutral; add water to the filter cake and beat to obtain a molecular sieve slurry with a solid content of 10% by weight, add 10.42 g of NaOH (purity 96%), heat up to 50 ° C and stir a...

Embodiment 2

[0074] Y molecular sieve (produced by Catalyst Qilu Branch, unit cell parameter 24.63 angstroms) and NH 4 Cl and distilled water were mixed and beaten evenly at a ratio of 1:1:10, ammonium was exchanged at 70°C for 1 hour, the sample was filtered, washed, and dried, and the sodium content of the molecular sieve was determined to be less than 5% by weight. The above-mentioned molecular sieves were calcined at 600° C. and 100% steam for 2 hours. Take 100g of roasted molecular sieve (mass on a dry basis) and add water to prepare a molecular sieve slurry with a solid content of 10% by weight, add 5g of oxalic acid during stirring, and then add 200g of sulfuric acid (mass fraction 10%) for 30 minutes; heat up to 30°C and stir at a constant temperature 2h, filter and wash until the filtrate is neutral; add water and beat the filter cake to obtain a molecular sieve slurry with a solid content of 10% by weight, add 31.25g KOH (purity 96%), heat up to 70°C and stir at a constant temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com