Catalytic conversion method and device for prolific low-carbon olefins

A technology of low-carbon olefins and catalysts, which is applied in the field of catalytic conversion and devices for high-yield low-carbon olefins, can solve the problems of no coupling optimization and further improvement in yield, and achieve increased yield, high hydrocarbon conversion capacity, high and low The effect of carboolefin yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

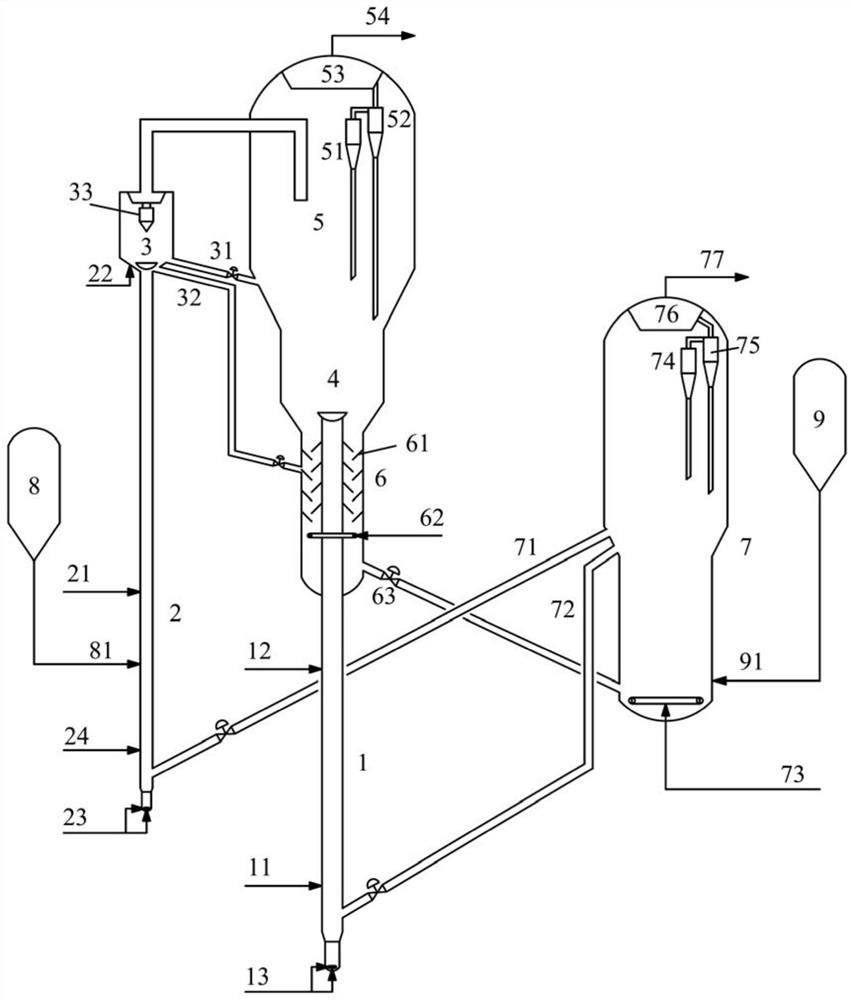

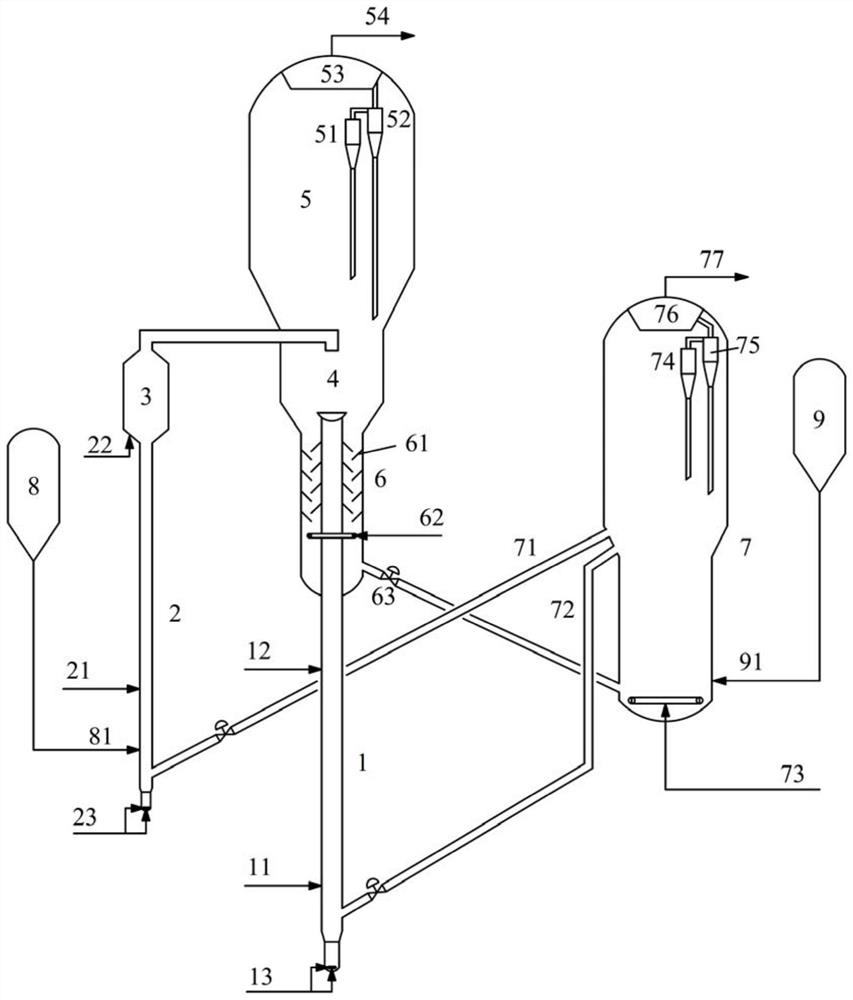

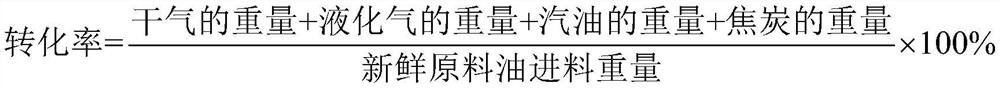

[0070]The tests were carried out on a medium-scale test rig. The plant includes two riser reactors and two fluidized bed reactors. The inner diameter of the first riser reactor 1 is 16mm, and the length is 3200mm. The inner diameter of the second riser reactor 2 is 16mm, and the height is 3000mm. The inner diameter of the second fluidized bed reactor 3 is 50mm, and the height is 300mm. The fluidized bed reactor 4 has an inner diameter of 64 mm and a height of 500 mm. The fresh raw oil is introduced into the bottom of the first riser reactor 1, contacts and reacts with the regenerated catalyst from the regenerator 7, and the reacted oil mixture is introduced into the first fluidized bed reactor 4; cracked heavy oil is introduced into the second riser for reaction The bottom of device 2 is contacted and reacted with the regenerated catalyst from regenerator 7, and the catalyst CAT-1 and C4 hydrocarbons (carbon tetraolefin content is 62.8% by weight) from catalyst storage tank 8...

Embodiment 2

[0072] According to the method of Example 1, the difference is that the C4 hydrocarbons obtained by fractionation are not introduced into the second riser reactor 2, and the light gasoline fraction obtained by fractionation (distillation range 40-80 ° C, olefin content is 65% by weight) Introduced into the second fluidized bed reactor 3, the mass ratio of light gasoline fraction to fresh raw oil is 0.1:1. The reaction conditions and results are shown in Table 3.

Embodiment 3

[0074] According to the method of Example 1, the difference is that in addition to introducing the C4 obtained by fractional distillation into the second riser reactor 2, the light gasoline fraction obtained by fractional distillation (distillation range 40-80 ° C, olefin content is 65% by weight) Introduced into the second fluidized bed reactor 3, the mass ratio of the C4 hydrocarbons, light gasoline fraction and fresh raw oil is 0.05:0.05:1. The reaction conditions and results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com