Milling grooving machining method for high-temperature alloy integral blade ring and blade part

A high-temperature alloy and integral leaf technology, applied in the field of mechanical processing, can solve the problems that a single cutter shaft cannot be rough-grooved, the space for the cutter is small, and the shape of the transfer R is complicated, so as to improve the material removal rate and processing efficiency, avoid The sharp increase in cutting force and the effect of improving machining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

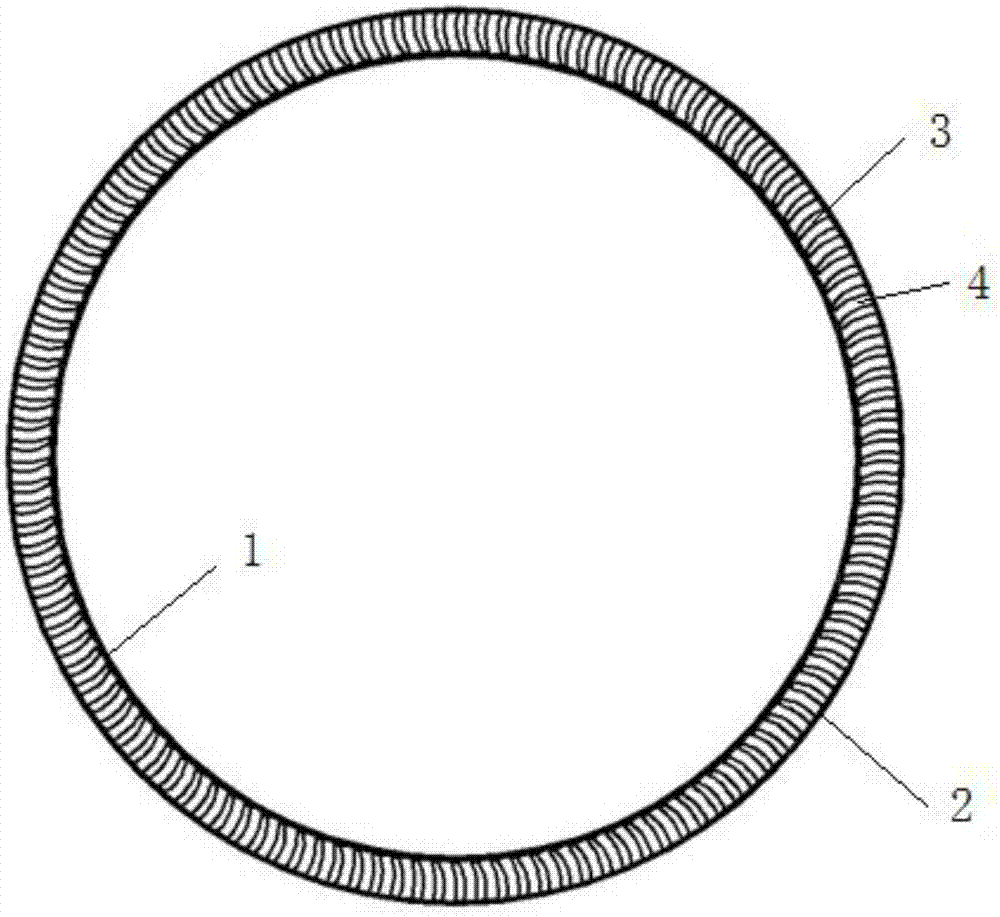

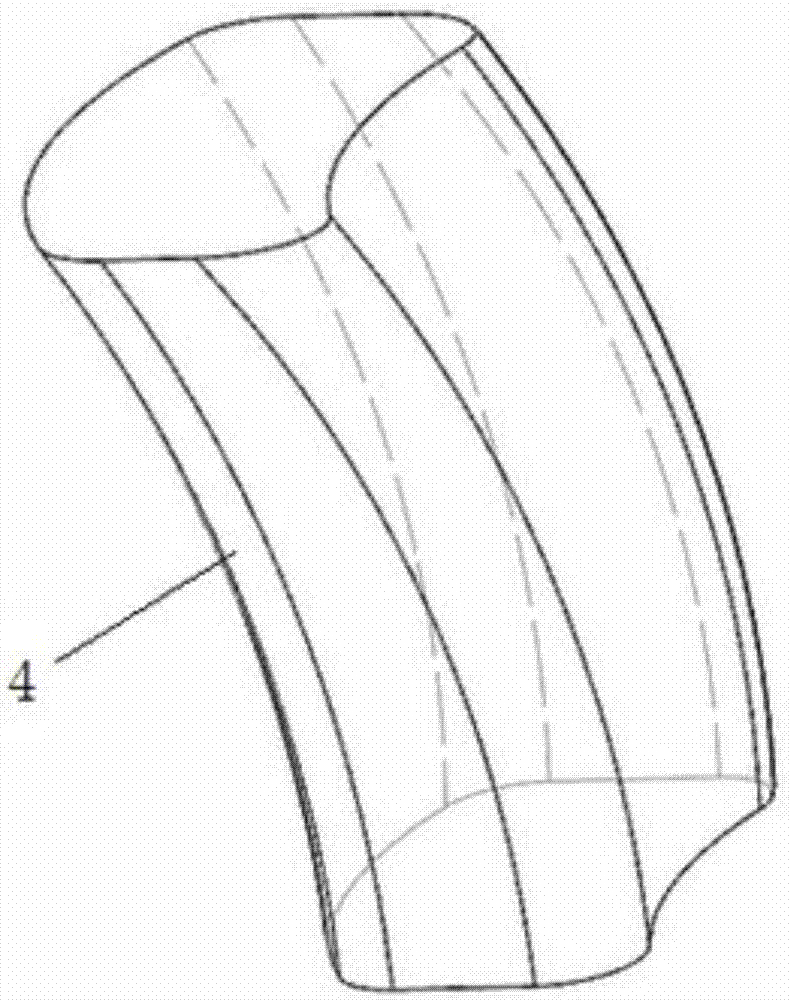

[0032] Such as figure 1 As shown, the integral leaf ring blade parts include inner ring 1, outer ring 2 and blade 3, the material grade is GH4169, the largest outer diameter size: Φ530mm; the smallest inner flow channel diameter size: Φ460mm; the thickness of the part is 30mm; the largest diameter of the blade 3 Chord width: 40mm; total number of blades 3: 130 pieces; minimum distance between adjacent blades 3: 9mm; thickness of inner ring 1 and outer ring 2 is 2-5mm; length of blade 3 is 30-33mm; R=2.5mm; between adjacent blades 3 is the entity 4 that needs to be slotted and removed.

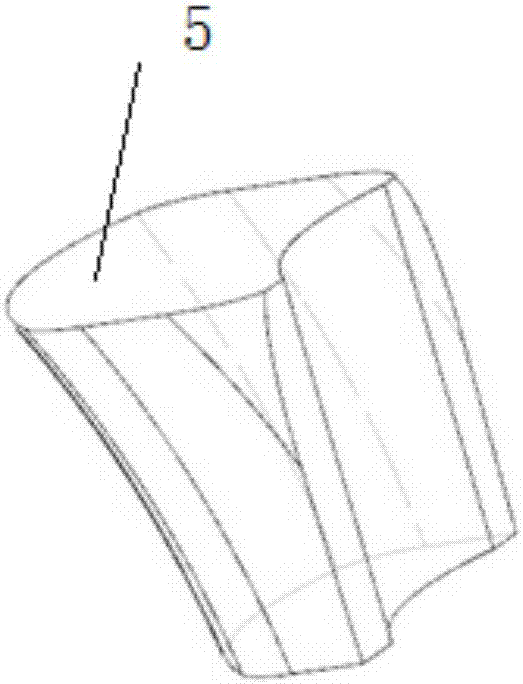

[0033] Such as figure 2 As shown, the entity 4 that needs to be slotted and removed can be simplified as an inverted conical hexahedron with a certain curvature, the length of the upper end is 35mm, the width is 10mm, the length of the lower end is 30mm, the width is 10mm, the narrowest position is 9mm, the height is 30mm, and the rounded corner R is 3mm.

[0034] The processing process incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com