Hot extrusion aluminum profile die

An aluminum profile, hot extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of low pass rate, large width, low extrusion production efficiency, etc., to achieve a reasonable overall structure design and pass the machine High rate, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

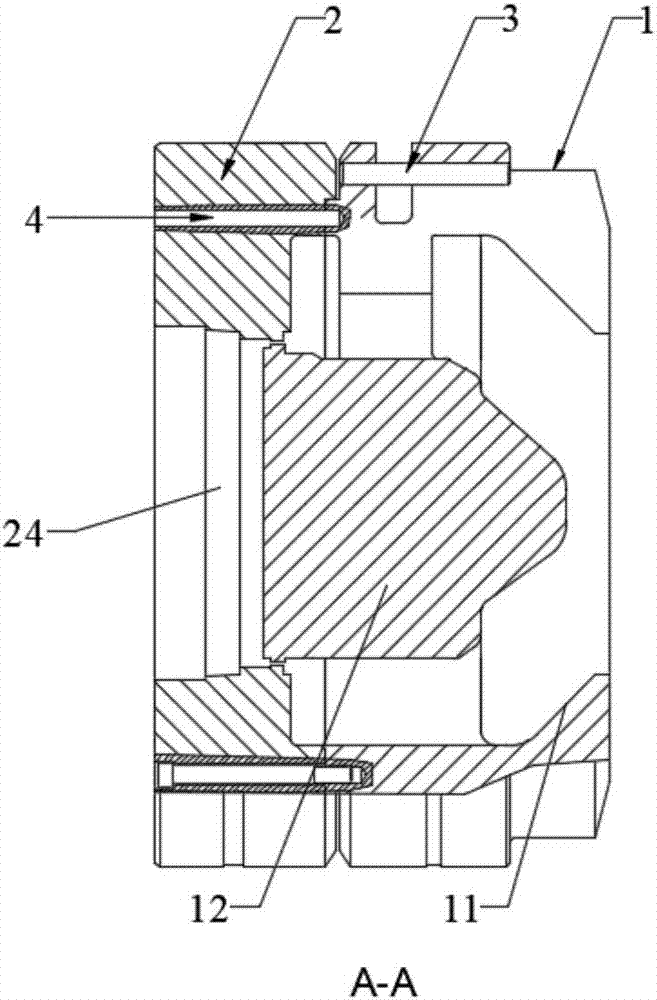

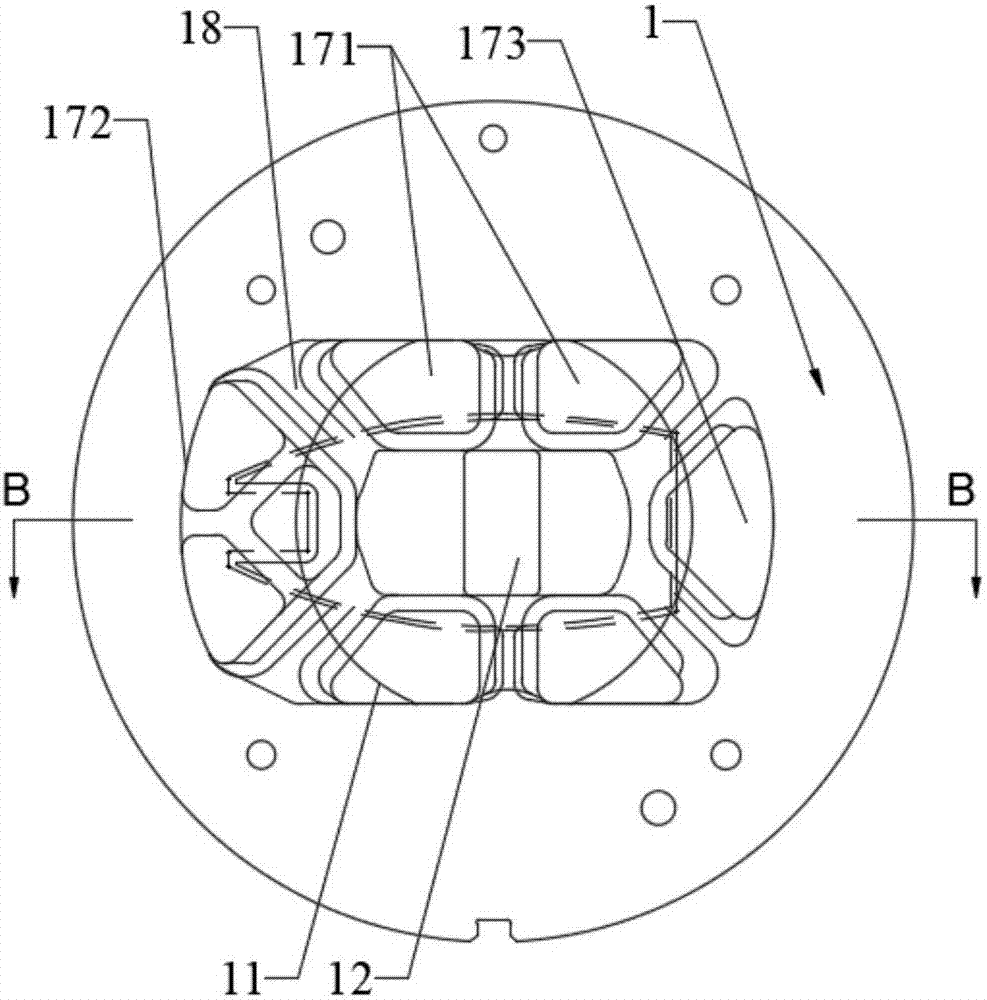

[0035] The preparation process of the above-mentioned hot extrusion aluminum profile mold is as follows: firstly, the first layer of the entrance of the upper mold 1 is made into a super-large wide-spreading curve taper 11 on both sides, which is similar to first converting a circular extrusion cylinder into a flat extrusion cylinder, which is equivalent to changing round ingot extrusion into flat ingot extrusion, increasing the supply of metal on both sides as much as possible; then the tongue core 12 located in the middle of the entrance side of the upper die 1 is designed as a flexible curved convex cone Platform structure, which distributes the metal flow, guides the metal flow to both sides through the flexible curved convex frustum structure, and the metal flow enters the lower die 2 through the diversion hole 17; the lower die 2 adopts a secondary welding chamber, through the first The welding chamber 21 and the second welding chamber 22, and a large mil is made at the b...

Embodiment 1

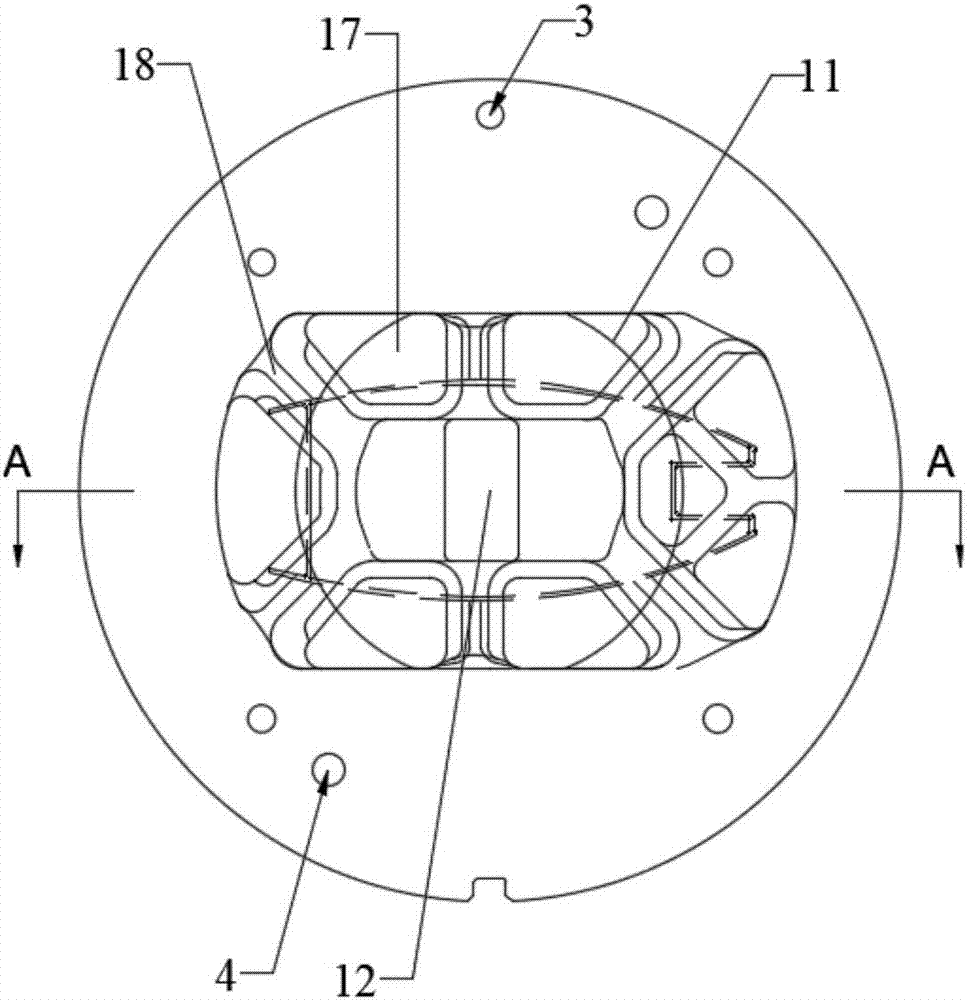

[0051] Please refer to Figure 1 to Figure 7 Shown, embodiment one of the present invention is:

[0052] A hot extruded aluminum profile die, comprising an upper die 1 and a lower die 2 connected to each other;

[0053] The entrance of the feed end of the upper die 1 is provided with a wide-spreading curved tapered surface 11; the middle part of the upper die 1 is provided with a tongue core 12, and the tongue core 12 is a frustum of cone structure with a circular arc protrusion at one end. , the arc protrusion of the tongue core 12 is located inside the upper die 1, and the other end of the tongue core 12 is located outside the discharge end of the upper die 1;

[0054] The opening of the tongue core 12 is provided with a first working belt 13, the right end of the first working belt 13 is provided with an upper empty knife 14, and the left end of the first working belt 13 is provided with a lower empty knife 15;

[0055] The discharge end of the upper mold 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com