Asymmetric-structure fuel cell positive and negative pole plates and galvanic pile formed by same

A fuel cell stack, asymmetric structure technology, applied in the direction of fuel cells, fuel cell grouping, circuits, etc., can solve the problems of homogeneity difference amplification, uneven distribution of battery flow, decrease and other problems, and achieve uniformity improvement and uniformity improvement. The effect of improving the volume specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

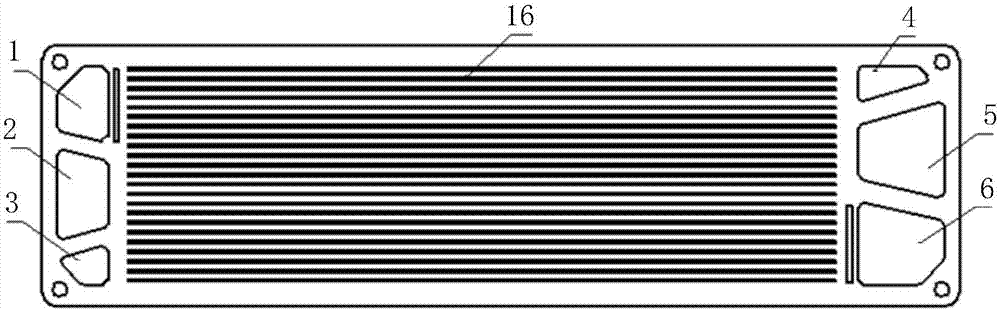

[0045] In the present embodiment, the area of the oxidant inflow channel on the cathode and anode plates is set to 15cm 2 , the ratio α of the area of the oxidant outflow channel to the area of the oxidant inflow channel is set to 1.5, and the area of the reductant inflow channel is set to 6 cm 2 , the ratio α of the area of the reducing agent outflow channel to the area of the reducing agent inflow channel is set to 1, and the area of the coolant inflow channel is set to 16cm 2 , the ratio α of the area of the coolant outflow channel to the area of the coolant inflow channel was set to 1.8. A 290-node electric stack is composed of the above-mentioned cathode, anode plates and membrane electrode structures.

[0046] The area of the oxidant inflow channel on the cathode and anode plates of the comparative example used is set to 15cm 2 , the ratio α of the area of the oxidant outflow channel to the area of the oxidant inflow channel is set to 1 / 1.5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com