Macromolecule nonmetal energy oil unstressed container mixed fuel-electricity integrated pulse steam equipment

A kind of steam equipment and non-metal technology, which is applied in the field of polymer non-metal energy oil non-pressure container mixed combustion and electricity integrated pulsating steam equipment, can solve the problems of large energy consumption, unsafe, large water consumption, etc., and achieve intelligent control High, quick pressure relief, pressure controllable and adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

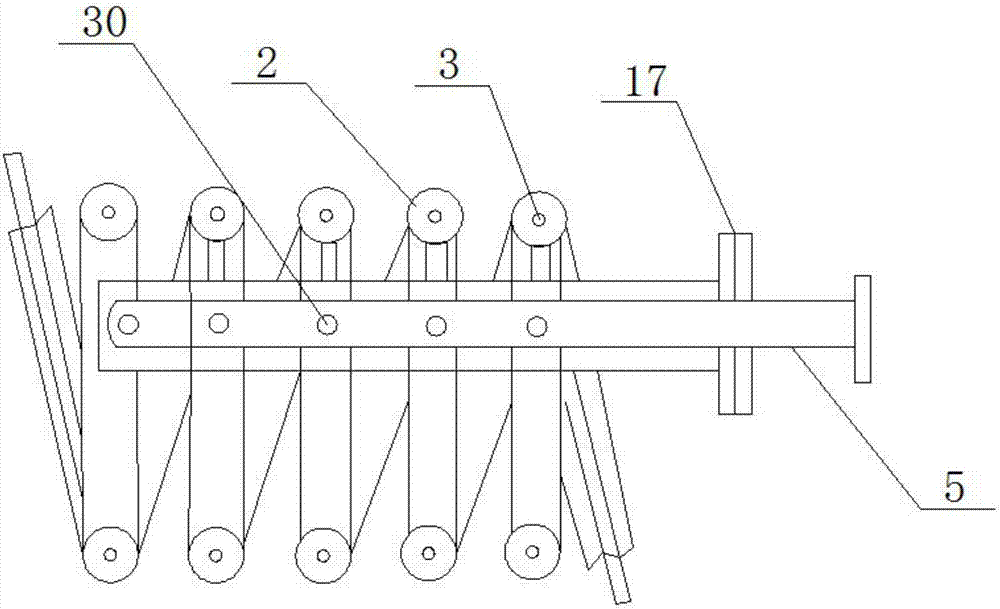

[0021] As a preferred embodiment of the present invention, a first smoke bin 15-1 is provided on one side of the flue pipe 15-2, and a second smoke bin 16 is arranged on one side of the lower flue pipe 15.

[0022] As a preferred embodiment of the present invention, the combustion bed 4 is further provided with a chain row 4-2, and the two ends of the chain row 4-2 are provided with a speed reducer and a driven wheel.

[0023] As a preferred embodiment of the present invention, the oil cylinder 10 is also provided with an air exchange absorption box and a high-mixing compressor.

[0024] As a preferred embodiment of the present invention, the secondary flash coil 7 is provided with a porous distributor 8 , and the balance pipe 9 is provided with an oil and gas pipe 11 .

[0025] As a preferred embodiment of the present invention, the combustion bin 14 is provided with a multi-hole flue gas exchange pipe and a flue gas reverse bin.

[0026] As a preferred embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com