Organic-inorganic compound alkali-free flash setting admixture and preparation method thereof

A composite, accelerator technology, applied in the fields of cement-based cementitious material chemical industry and concrete admixtures, can solve the problems of poor adaptability of alkali-free accelerators, achieve obvious strength increase, increase dissolution rate, and reduce crystallization. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

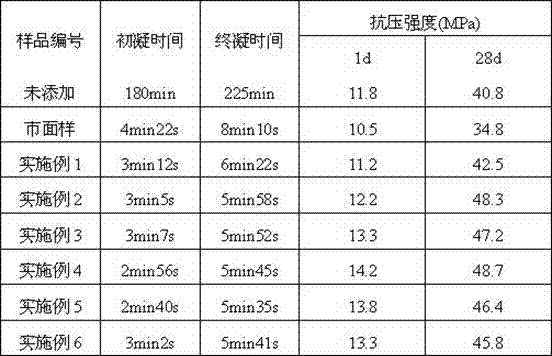

Examples

Embodiment 2

[0080] Step 1, according to total mass parts as 100 parts, weighing

[0081] Nitric acid: 1 part;

[0082] Citric acid: 0.2 parts;

[0083] Aluminum sulfate: 20 parts;

[0084] Calcium sulfate: 6.5 parts

[0085] Diethanolamine: 3.8 parts;

[0086] Industrial grade polyaluminum sulfate: 24 parts;

[0087] Lower alcohol: a composition of ethylene glycol and glycerol with a mass ratio of 1:1, 0.5 parts;

[0088] Wetting agent: a composition of nonylphenol polyoxyethylene ether phosphate monoester and propylene glycol polyoxypropylene polyoxyethylene block polyether with a mass ratio of 1:1, 0.2 parts;

[0089] Anti-settling agent: a mixture of PEG800 modified organobentonite and amide-modified hydrogenated castor oil with a mass ratio of 2:1, 0.05 part;

[0090] The remainder is water;

[0091] Step 2, prepare the aqueous solution of alkanolamine metal complex, specifically as follows:

[0092] 1) Add mineral acid, complexing agent, metal sulfate and 25 parts of water in...

Embodiment 3

[0099] Step 1, according to total mass parts as 100 parts, weighing

[0100] Nitric acid: 1 part;

[0101] Phosphoric acid: 2 parts;

[0102] Tartaric acid: 0.8 parts;

[0103] Aluminum sulfate: 18.7 parts;

[0104] Magnesium sulfate: 3.3 parts

[0105] Diethanol monoisopropanolamine: 6.5 parts;

[0106] Polyaluminum sulfate: 21 parts;

[0107] Lower alcohol: a composition of ethylene glycol and glycerol with a mass ratio of 1:1, 2 parts;

[0108] Wetting agent: a composition of nonylphenol polyoxyethylene ether phosphate monoester and tetradecyl polyoxyethylene ether succinic acid monoester sulfonate with a mass ratio of 1:1, 0.15 parts;

[0109] Anti-settling agent: a mixture of PEG800 modified organobentonite and amide-modified hydrogenated castor oil with a mass ratio of 2:1, 0.02 parts;

[0110] The remainder is water;

[0111] Step 2, prepare the aqueous solution of alkanolamine metal complex, specifically as follows:

[0112] 1) Add mineral acid, complexing age...

Embodiment 4

[0119] Step 1, according to total mass parts as 100 parts, weighing

[0120] Phosphoric acid: 1 part;

[0121] Sodium alginate: 0.2 parts;

[0122] Aluminum sulfate: 22 parts;

[0123] Iron sulfate: 3.7 parts

[0124] Monoethanol diisopropanolamine: 3.5 parts;

[0125] Industrial grade polyaluminum sulfate: 25 parts;

[0126] Lower alcohol: a composition of ethylene glycol and glycerol with a mass ratio of 1:1, 1.5 parts;

[0127] Wetting agent: a composition of nonylphenol polyoxyethylene ether phosphate monoester and aliphatic amine polyoxyethylene ether sulfosuccinic acid monoester disodium salt with a mass ratio of 1:1, 0.2 parts;

[0128] Anti-settling agent: a mixture of PEG800 modified organobentonite and amide-modified hydrogenated castor oil with a mass ratio of 2:1, 0.04 parts;

[0129] The remainder is water;

[0130] Step 2, prepare the aqueous solution of alkanolamine metal complex, specifically as follows:

[0131] 1) Add mineral acid, complexing agent, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com