Industrial dust removal apparatus

A dust removal device, industrial technology, used in transportation and packaging, fixed tubular conduit assemblies, dispersed particle filtration, etc., to avoid fire or explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

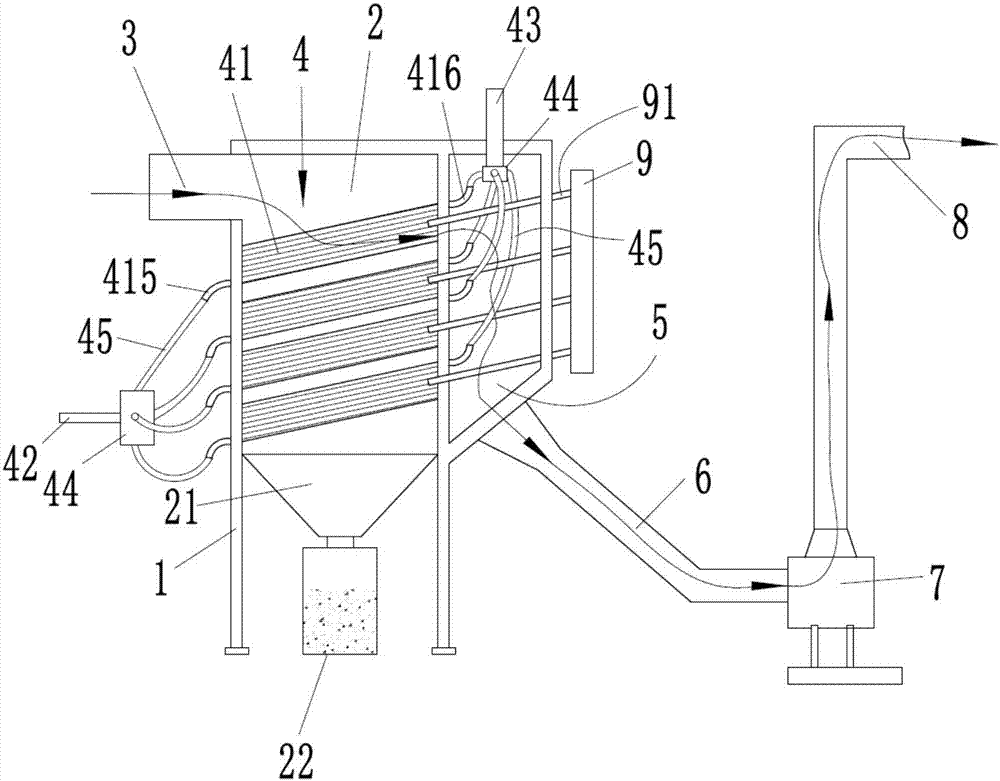

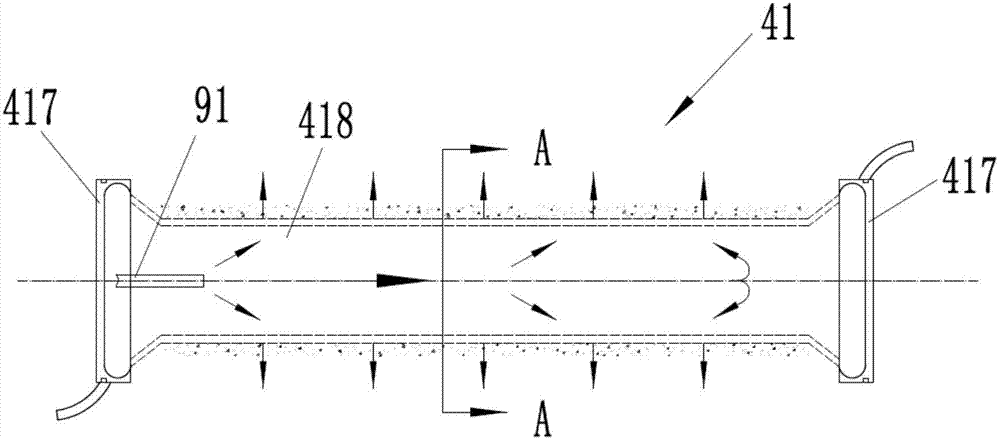

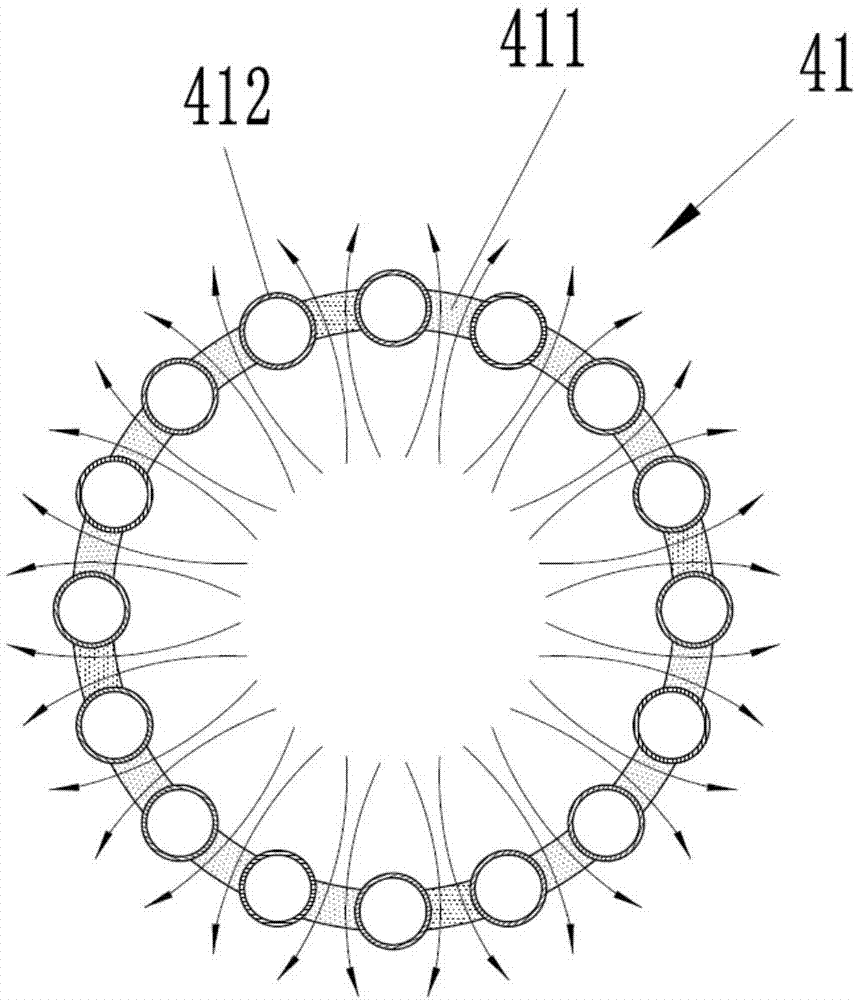

[0028] Refer below Figure 1 to Figure 6 To further explain this application, such as figure 1 The shown industrial dust removal device includes a frame 1, an air outlet pipe 6, an exhaust fan 7 and an exhaust pipe 8. An air intake chamber 2 is arranged above the frame 1, and a dust-carrying gas chamber is provided at the top left end of the air inlet chamber 2. The air inlet 3, the bottom of the air inlet chamber 2 is connected with a dust collection funnel 21, the bottom of the dust collection funnel 21 is provided with a detachable dust collection box 22, and the right side of the air inlet chamber 2 is provided with a separated air outlet chamber 5 , the air outlet pipe 6 is connected to the bottom of the air outlet chamber 5, the exhaust fan 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com