Anti-reflection infrared-resisting coated resin lens and preparation method thereof

A resin lens and anti-infrared technology, which is applied in optical components, instruments, optics, etc., can solve the problems of colored sunglasses such as unclear vision, dry eyes, and poor color discrimination performance, so as to reduce production and operation costs and diversify products , The coating material is simple and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

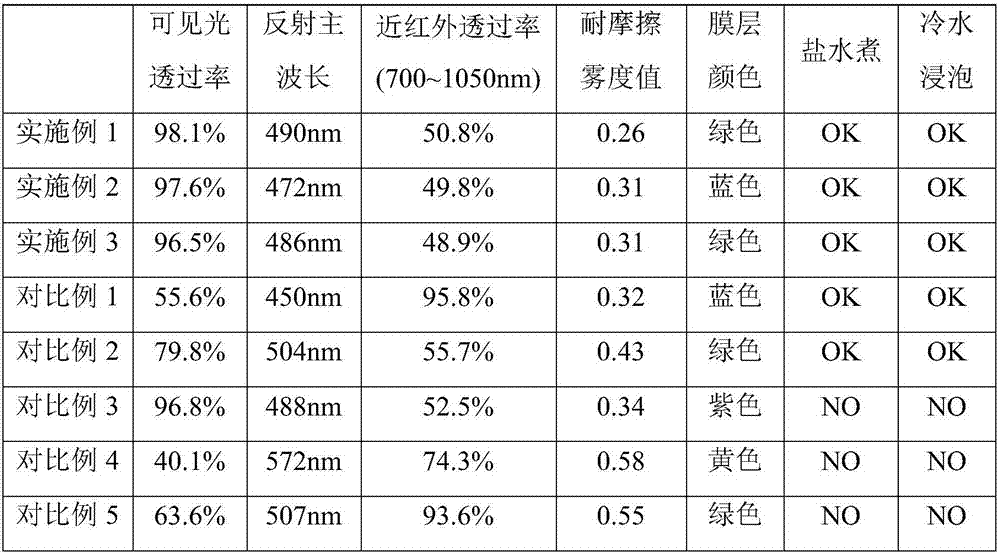

Examples

Embodiment 1

[0037] An anti-reflection and anti-infrared coating resin lens is prepared through the following steps:

[0038] (1) washing and drying the lens matrix for subsequent use;

[0039] (2) Dip-coat the lens substrate treated in step (1) in the hardening solution, and then cure it at 120°C for 2 hours to obtain a hardening layer with a thickness of 2.0 μm; the hardening solution is nano-silicon oxide The solution prepared by mixing with methanol according to the mass ratio of 1:9.

[0040] (3) The anti-reflection and anti-infrared film layer chooses 9-layer structure. Put the lens with the hardened layer into the vacuum evaporation coating chamber, and use the magnetic field to deflect the electron beam to evaporate the material sequentially to coat the hardened layer; the temperature of the coating chamber is set at 50-60°C, and the vacuum is pumped to 2.0×10 -5 Pa starts the electron gun and sets the evaporation rate of each layer of burning powder, the first layer of zirconium...

Embodiment 2

[0043] An anti-reflection and anti-infrared coating resin lens is prepared through the following steps:

[0044] (1) washing and drying the lens matrix for subsequent use;

[0045] (2) Dip-coat the lens substrate treated in step (1) in the hardening solution, and then cure it at 110°C for 2 hours to obtain a hardening layer with a thickness of 2.0 μm; the hardening solution is nano-oxidized A solution prepared by mixing silicon and methanol at a mass ratio of 1:9.

[0046] (3) The anti-reflection and anti-infrared coating layer chooses an 8-layer structure. Put the lens with the hardened layer into the vacuum evaporation coating chamber, and use the magnetic field to deflect the electron beam to evaporate the material sequentially to coat the hardened layer; the temperature of the coating chamber is set at 50-60°C, and the vacuum is pumped to 2.0×10 -5 Pa started to start the electron gun and set the evaporation rate of each layer, the first layer of silicon dioxide layer 1....

Embodiment 3

[0049] An anti-reflection and anti-infrared coating resin lens is prepared through the following steps:

[0050] (1) washing and drying the lens matrix for subsequent use;

[0051] (2) Dip-coat the lens substrate treated in step (1) in the hardening solution, and then cure it at 110°C for 2 hours to obtain a hardening layer with a thickness of 2.5 μm; the hardening solution is nano-oxidized A solution prepared by mixing silicon and methanol at a mass ratio of 1:9.

[0052] (3) The anti-reflection and anti-infrared film layer chooses 9-layer structure. Put the lens with the hardened layer into the vacuum evaporation coating chamber, and use the magnetic field to deflect the electron beam to evaporate the material sequentially to coat the hardened layer; the temperature of the coating chamber is set at 50-60°C, and the vacuum is pumped to 2.0×10 -5 Pa starts the electron gun and sets the evaporation rate of each layer of burning powder, the first layer of zirconium dioxide lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com