Polyester fabric dyeing method

A dyeing method and fabric technology, applied in the field of dyeing, can solve problems such as uneven dyeing, inability to dye with dyeing equipment, simple and rough dyeing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

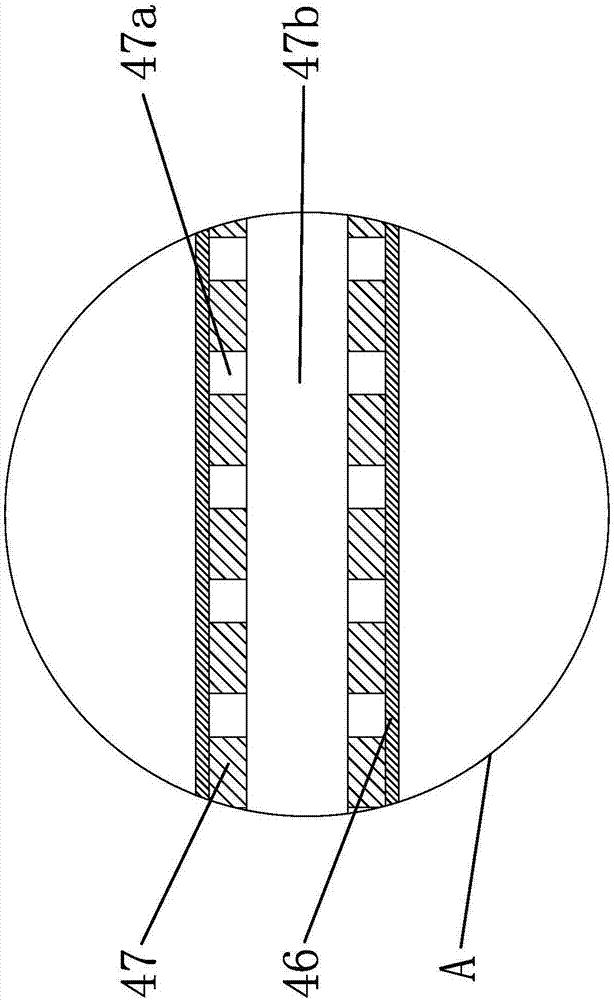

Image

Examples

Embodiment Construction

[0083] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0084] The dyeing method of this polyester fabric, this dyeing method comprises the following steps:

[0085] S1. Pre-treat the fabric first, including fabric preparation, singeing, desizing, scouring, bleaching and mercerizing;

[0086]S2, 0.8-1.5 parts by weight of butyl peroxybenzoate, 1.6 parts by weight of sodium sulfate, 2.8 parts by weight of hydroxypropyl methylcellulose, 2.6 parts by weight of acrylate, and 45 parts by weight of plant dyes are successively dropped into 160 parts by weight Deionized water, and heated to 50 ° C, stirred evenly, to obtain semi-finished dyes; in the present embodiment, butyl peroxybenzoate is 1.1 parts by weight;

[0087] S3, in the dye of the semi-finished product obtained in S2, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com