Management method of electrolytic aluminum whole life cycle

A technology with a full life cycle and management method, applied in the field of electrolytic aluminum management, can solve problems that affect the life of electrolytic cells, maintain a single electrolytic aluminum plant, and fail to grasp and analyze aluminum electrolytic production, so as to improve the life of electrolytic cells and electrolytic production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

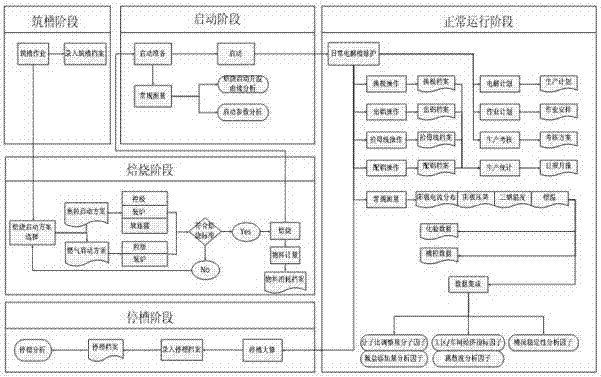

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] As shown in the figure, a management method for the whole life cycle of electrolytic aluminum in the present invention includes the tank building stage, the roasting stage, the start-up stage, the normal production and operation stage, and the tank stop stage;

[0027] Among them, the trenching stage: during the construction period, set up construction standards and process requirements for the construction unit, and manage and record the construction information; the construction information in the trenching stage is entered into the trenching file.

[0028] Roasting stage: during the roasting period, record the material information, operation information, and cell condition information of the electrolyzer; select the roasting start-up plan during the roasting stage, including the coke particle start-up plan and the gas start-up plan; the coke particle start-up plan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com