Automatic material sorting system based on near infrared spectrum

A near-infrared spectrum and sorting system technology, which is applied in the field of automated material sorting systems, can solve problems such as excessive waste water, non-environmental protection, and poor precision, and achieve the effects of low material requirements, fast sorting speed, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

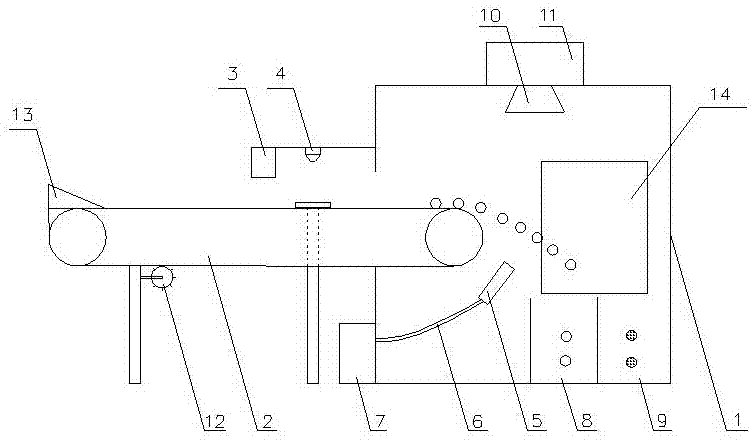

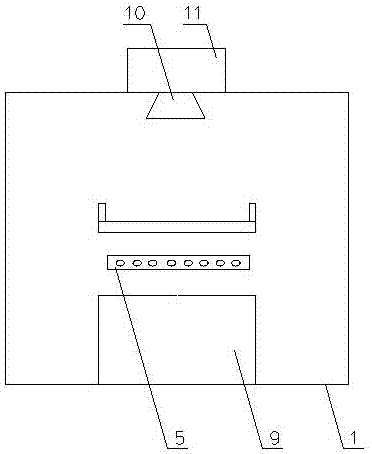

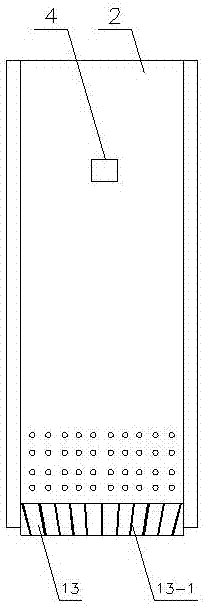

[0011] like Figure 1-3 As shown, the present invention includes a housing 1, a conveyor belt 2, a near-infrared light emitter 3, an infrared light detection probe 4, a group of nozzles 5, an air supply pipe 6, a high-pressure air pump 7, a first storage tank 8, and a second storage tank 9. Dust collection cover 10, fan 11, brush roller 12 and material guide mechanism 13, the left side of the conveyor belt 2 is the feed end, the right side is the discharge end, the conveyor belt 2 discharge end is located in the shell 1, near infrared The light emitter 3 and the infrared light detection probe 4 are respectively installed above the conveyor belt 2, and the near-infrared light emitter 3 is located on one side of the infrared light detection probe 4, and the group of nozzles 5 is evenly distributed below the discharge end of the conveyor belt 2, The high-pressure air pump 7 is provided with an air storage tank, and the high-pressure air pump 7 produces high-pressure air and store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com