Coil panel, manufacturing method thereof and electromagnetic heating equipment

A manufacturing method and coil disk technology, which are applied in the directions of electric/magnetic/electromagnetic heating, coil device, electric heating device, etc., can solve the problems of high manufacturing cost, single coil form, complicated winding process, etc., and achieve low manufacturing cost and reduced cost. Production cost, simple effect of winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

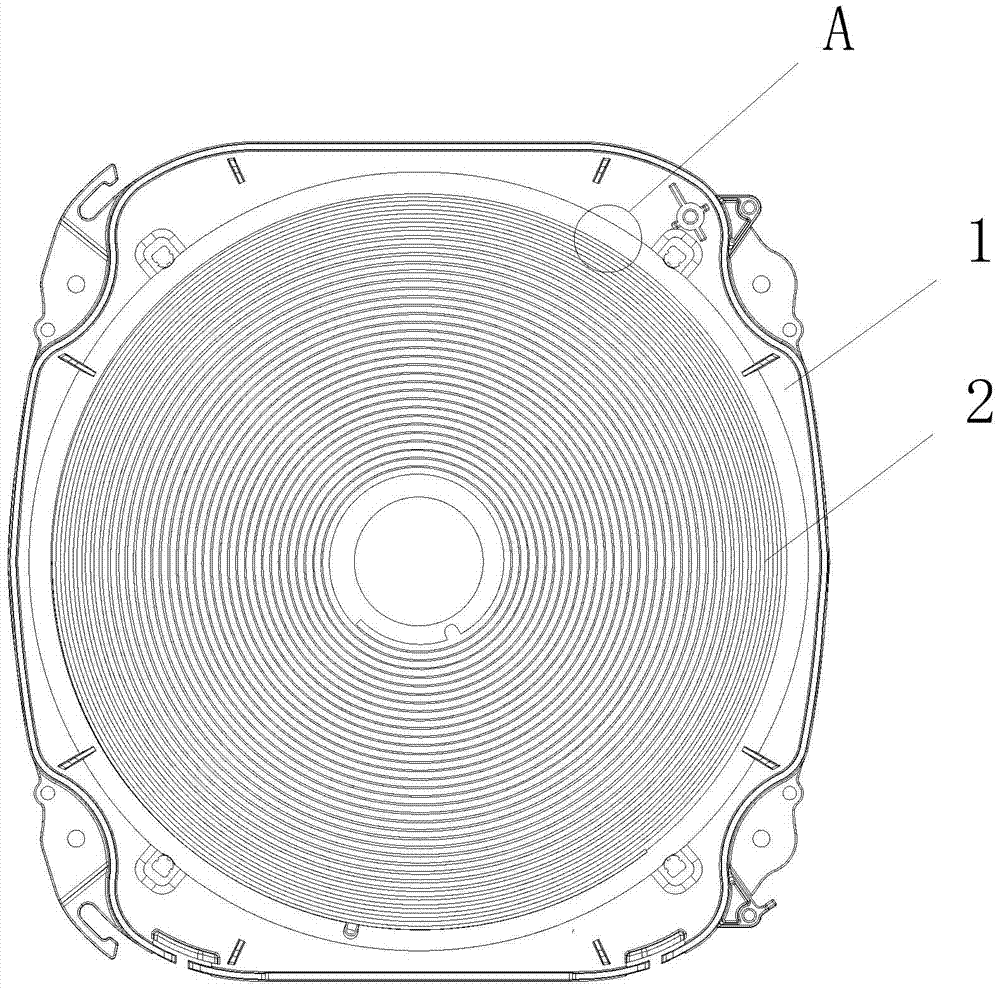

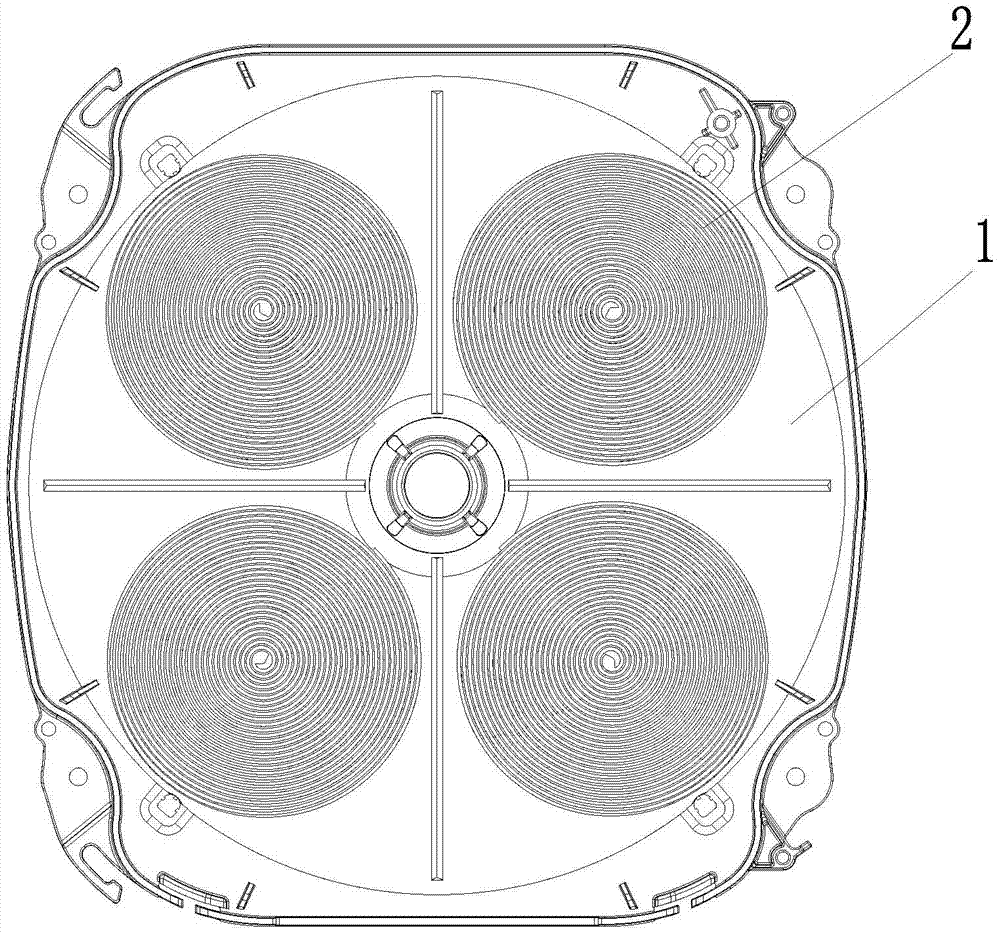

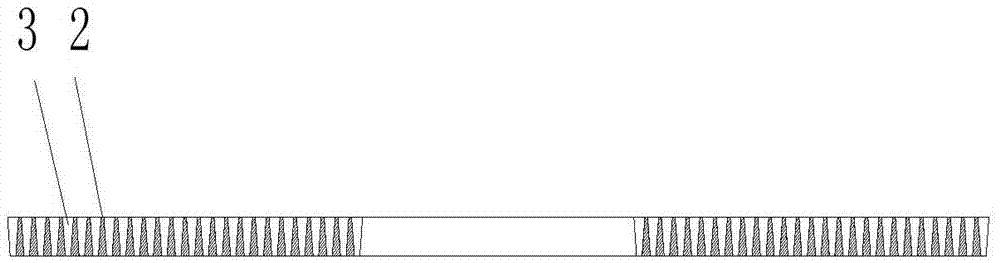

[0053] Such as figure 1 As shown, the coil disk provided in this embodiment includes a carrier 1, and the carrier 1 has at least one group of partition walls 2 extending according to a predetermined winding path, and insulating grooves 3 are formed between adjacent partition walls 2. A noble metal layer 6 formed through activation treatment is attached, and a conductive layer 4 is attached to the noble metal layer 6 .

[0054]It can be seen that the coil disc provided in this embodiment is directly wound on the surface of the carrier 1 to form a coil by attaching the conductive layer 4 . Structures such as limiting grooves and positioning ribs for clamping coils are provided on the upper body, making the structure of the carrier 1 simpler; and coils of various shapes can be wound according to user needs, which has the characteristics of flexible production. In addition, the manufacturing efficiency of this coil disk is much higher than the previous method of winding copper wi...

Embodiment 2

[0072] Such as Figure 7 As shown, the present embodiment provides a method for manufacturing a coil disk, the method includes the following steps:

[0073] S10, forming the carrier 1;

[0074] In this step S10, different molding methods can be adopted according to the material of the carrier 1: when the material of the carrier 1 is plastic, the molten plastic is injected into the mold to form the carrier 1; when the material of the carrier 1 is ceramic, the porcelain clay is first passed through The mold is extruded into a blank, and then the blank is sintered into a carrier 1; when the material of the carrier 1 is metal coated with an insulating material, the metal material is stamped first, and then an insulating layer is formed on the metal by spraying or injection molding.

[0075] S20, performing activation treatment on the carrier 1, so as to attach the noble metal layer 6 on the surface of the carrier 1;

[0076]The specific method for attaching the precious metal la...

Embodiment 3

[0098] This embodiment also provides an electromagnetic heating device, which includes the coil disk in Embodiment 1 to Embodiment 2. The coil disk includes a carrier 1, and the carrier 1 has at least one set of partition walls 2 extending along a predetermined winding path, an insulating groove 3 is formed between adjacent partition walls 2, and precious metals formed by activation treatment are attached to the partition walls 2 Layer 6, the conductive layer 4 is attached on the noble metal layer 6. As for the material and molding method of the coil disk carrier 1, the molding method of the partition wall 2 and the insulating groove 3, the composition of the conductive layer 4 and the method of attaching the conductive layer 4 to the partition wall 2, etc., all can refer to the description of the coil disk above. I won't repeat them here.

[0099] The electromagnetic heating equipment includes an electromagnetic cooker, a frying machine, a soybean milk machine, an electric k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com