Preparation method of bean curd skin

A technology for bean curd skin and soybeans, which is applied to the preservation of dairy products and food ingredients as antimicrobials, food preservation and other directions, can solve the problems of low processing efficiency, short shelf life, easy breakage, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

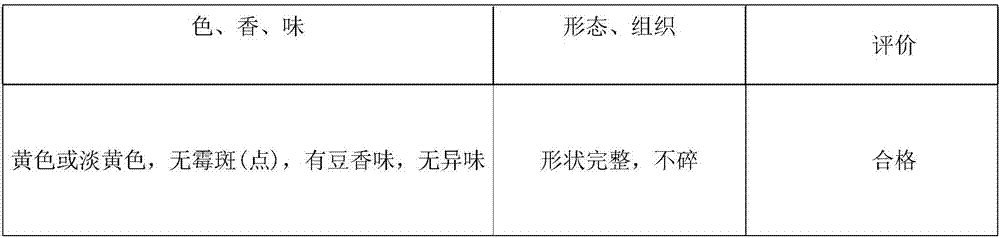

Examples

Embodiment 1

[0036] Embodiment 1: as figure 1 Shown, a kind of preparation method of bean curd skin comprises the following steps:

[0037] (1) Material selection: use soybeans with large grains, uniformity, fullness, no mildew, and no impurities as raw materials;

[0038] (2) Soaking: Soak soybeans in water. The weight ratio of soybeans to water is 1:3. Control the soaking time according to the water temperature and soybean variety. -12°C, soaking time is 12-15 hours, summer temperature is 28-33°C, soaking time is 5-7 hours, winter temperature is around 0°C, soaking time is 18-24 hours;

[0039] (3) Refining: Grinding the soaked soybeans with water to obtain a paste, the requirements for the paste after crushing: not rough or rough, uniform and white, no grain body, and the paste particle size is less than 3 microns;

[0040] (4) Centrifugal filtration: Grinding and centrifuging for 2-3 cycles to separate pulp and slag, and throwing out bean dregs to obtain raw pulp. The solid content o...

Embodiment 2

[0046] Example 2: A method for preparing bean curd skin. The difference from Example 1 is that the ratio of soybeans and water in step (2) is 1:4.

Embodiment 3

[0047] Example 3: A method for preparing bean curd skin, the difference from Example 1 is that the weight-number ratio of soybeans and water in step (2) is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com