A ferro-resistance variable memory and its writing method, reading method and preparation method

An iron resistance variable memory technology, which is applied to electrical components and other directions, can solve the problems of low storage density, increase the resistance ratio of high and low resistance states, and increase the storage window of the iron resistance variable memory, so as to increase the storage window, increase the The effect of the on-off ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

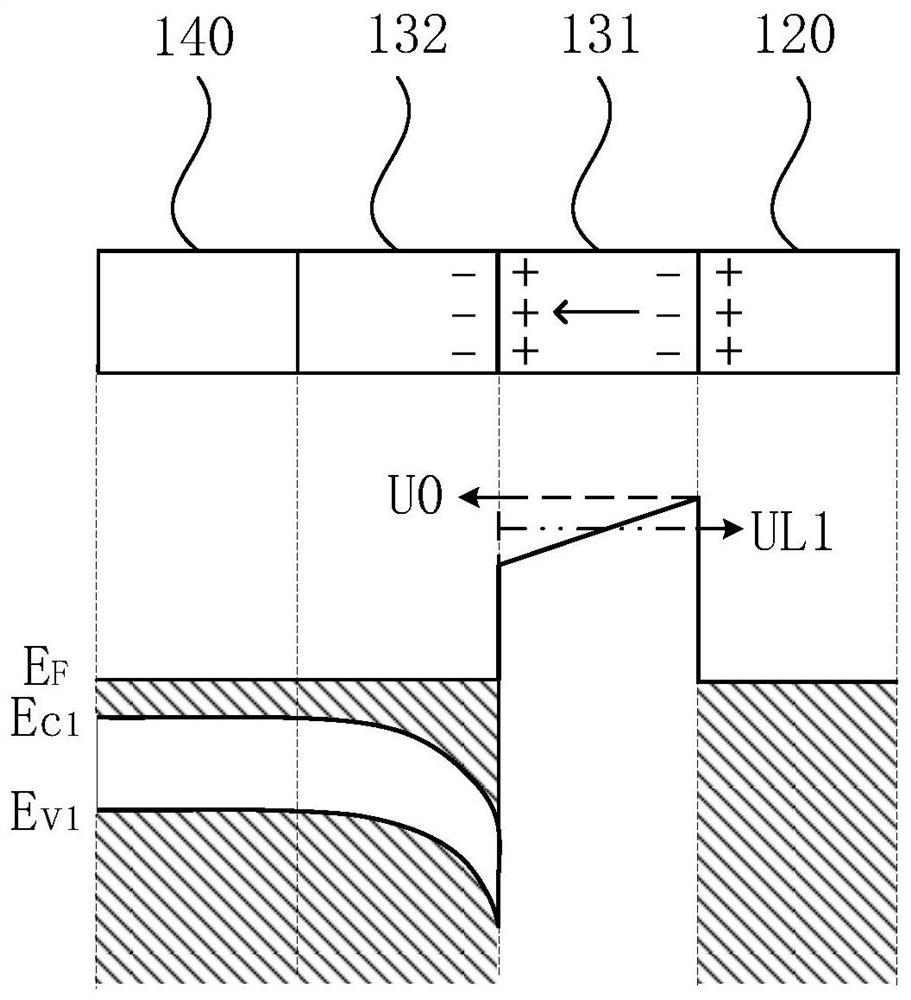

[0043] Usually, the conventional ferro-RRAM directly injects electrons from the top electrode (for example, a metal material layer) to the ferroelectric layer. When the material of the bottom electrode is the same, the conductivity of the top electrode determines the degree of difficulty of electron injection, that is The resistance ratio (R OFF / R ON ). The current RRAM R OFF / R ON less than 10 3 , that is, the storage window is small.

[0044] Wherein, the resistance ratio of the high and low resistance states of the switch layer determines the size of the storage window of the FRAM; meanwhile, the size of the storage window of the FRAM directly determines the storage density of the FRAM. Specifically, the greater the resistance ratio of the high and low resistance states of the switch layer is, the larger the storage window of the ferro-resistance variable memory is, and thus the higher the storage density of the ferro-resistance variable memory is.

[0045] Based on ...

Embodiment 2

[0082] Figure 10 It is a schematic flowchart of a writing method of a ferro-resistive variable memory provided in Embodiment 2 of the present invention, see Figure 10 , on the basis of the first embodiment above, the ferroelectric RRAM provided by this embodiment includes a substrate layer, a bottom electrode, a switch layer and a top electrode stacked in sequence; the switch layer includes a ferroelectric layer and is adjacent to the ferroelectric layer at least one semiconductor layer. The writing method of the ferro-resistive variable memory provided in this embodiment includes:

[0083] S210. Obtain a write instruction of the ferro-resistive variable memory.

[0084] Wherein, the write instruction refers to a machine instruction obtained by a control circuit connected to the ferro-resistive variable memory, which exemplarily includes corresponding instructions such as typing characters or pasting pictures, and the acquisition path exemplarily includes using a keyboard ...

Embodiment 3

[0093] Figure 11 It is a schematic flowchart of a method for reading ferro-resistive memory provided in Embodiment 3 of the present invention, see Figure 11 , on the basis of the first embodiment above, the ferroelectric RRAM provided by this embodiment includes a substrate layer, a bottom electrode, a switch layer and a top electrode stacked in sequence; the switch layer includes a ferroelectric layer and is adjacent to the ferroelectric layer at least one semiconductor layer. The writing method of the ferro-resistive variable memory provided in this embodiment includes:

[0094] S310. Obtain a read instruction of the FRAM.

[0095] Wherein, wherein, the reading instruction refers to a machine instruction obtained by a control circuit connected to the ferro-resistive variable memory, exemplarily including instructions corresponding to displaying characters, displaying pictures, playing audio and video, etc., and the obtaining path includes clicking the mouse and other ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com