Preparation method and application of cigarette filter tip and graphene composite material

A composite material and filter technology, which is applied in the field of cigarette filter/graphene composite material and cigarette filter/graphene composite material preparation, can solve the problem of low recovery rate and achieve simple process, good environmental and economic benefits, and excellent The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

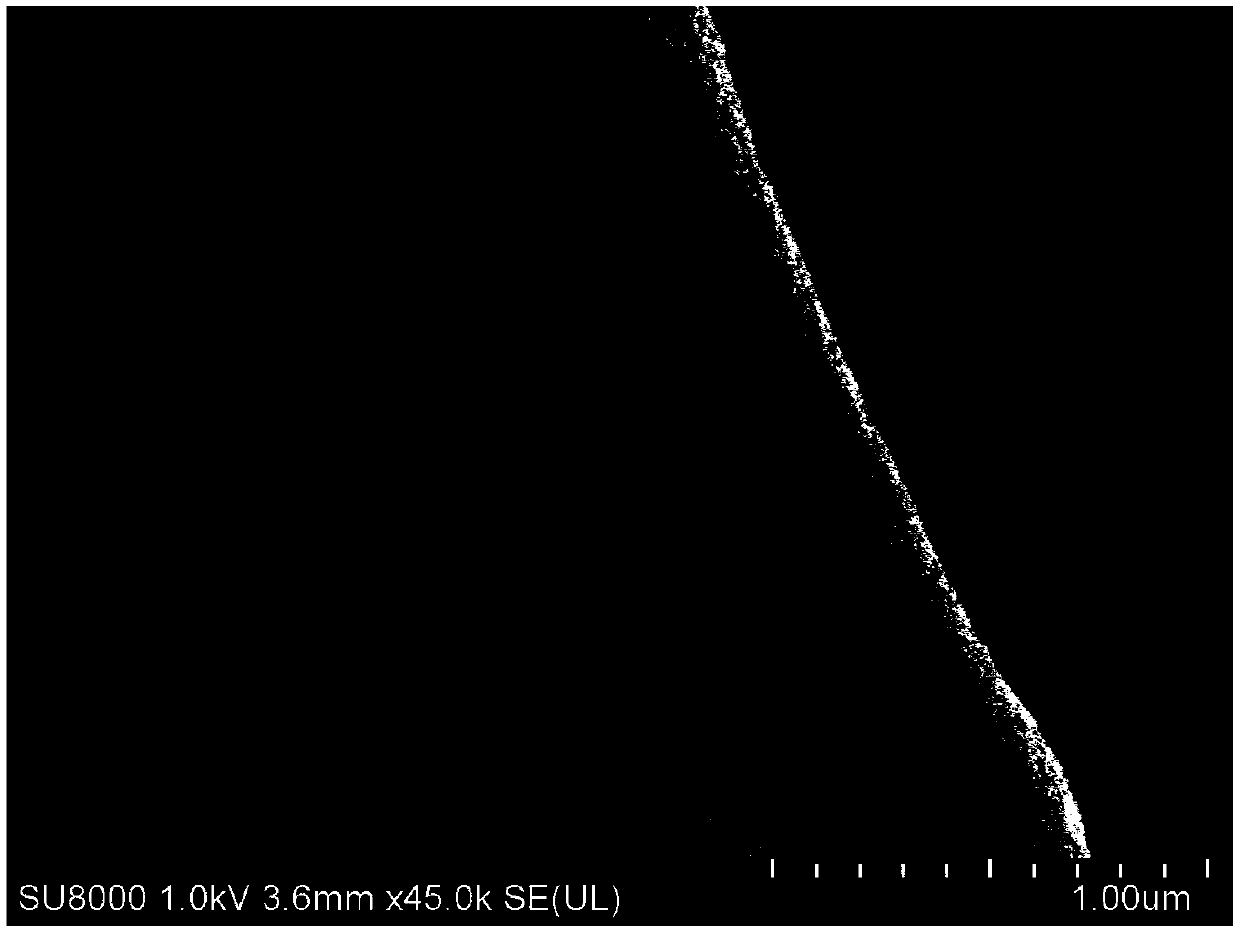

[0032] Disperse 8 mg of graphene in 40 ml of ethanol and ultrasonically disperse for 30 min. According to the mass-volume ratio of the cigarette filter tip and the dispersion liquid being 0.01g / ml, soak the waste cigarette filter tip in the ethanol dispersion liquid of graphene for 20s, then remove it and place it on a petri dish for 3min. Subsequent immersion in the dispersion was repeated 10 times. Dry the soaked cigarette filter in an oven at a temperature of 70° C. for 2 hours. The dried cigarette filter was placed in a crucible and carbonized in a tube furnace. Firstly, nitrogen gas is introduced with a flow rate of 40 sccm. The temperature of the furnace is raised to 800°C-820°C and then kept for 180 minutes at a heating rate of 10-20°C / min. After the furnace cools down to room temperature, the nitrogen gas is turned off. Obtained cigarette filter tip / graphene composite SEM picture such as figure 1 As shown, the porous structure of the composite material can be clearl...

Embodiment 2

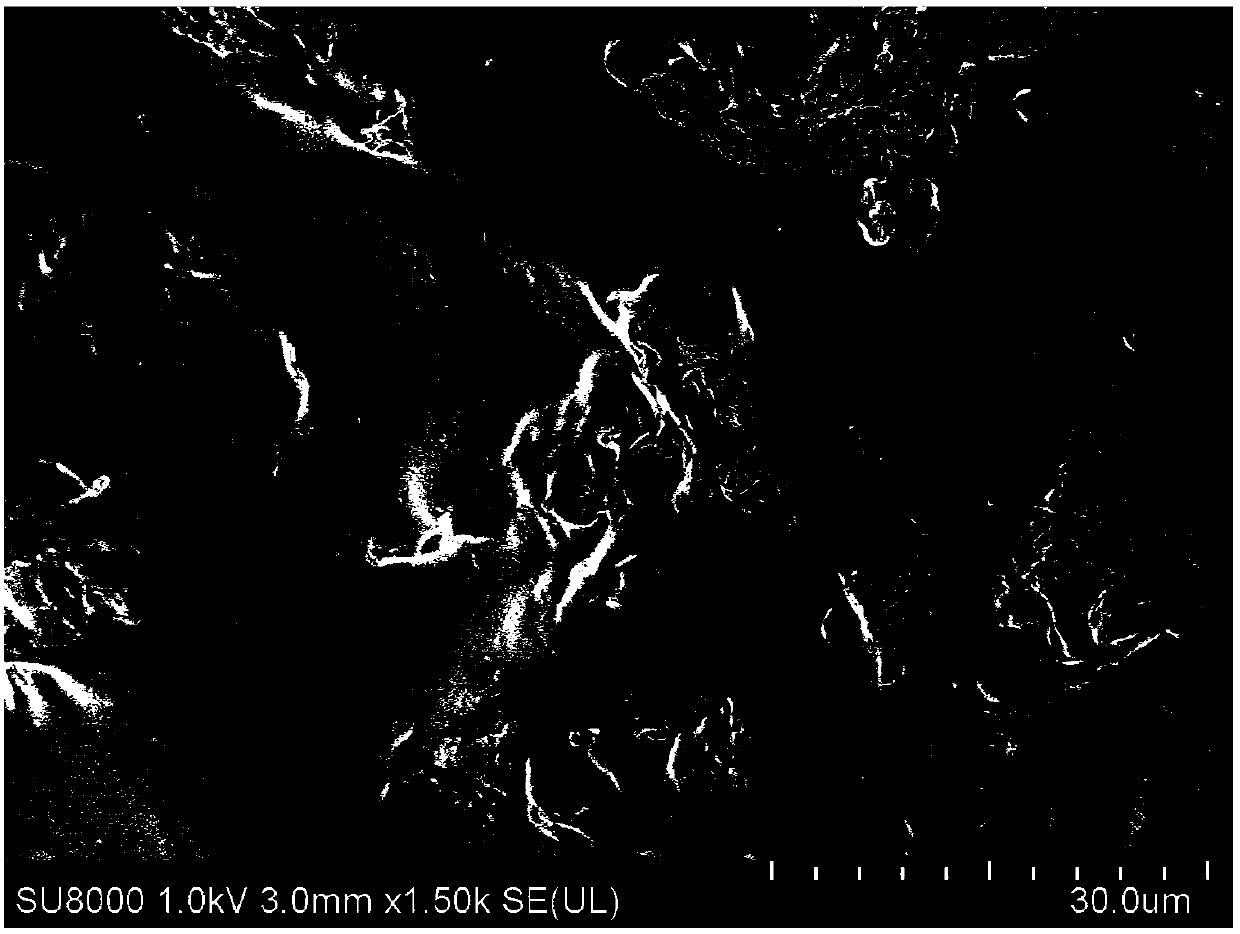

[0034] Disperse 20mg of graphene in 40ml of ethanol and ultrasonically disperse for 30min. According to the mass-volume ratio of the cigarette filter to the dispersion liquid of 0.15 g / ml, soak the waste cigarette filter in the ethanol dispersion of graphene for 60 seconds, then remove it and place it on a petri dish for 3 minutes. Subsequent immersion in ethanol dispersion, this process was repeated 15 times. Dry the soaked cigarette filter in an oven at a temperature of 100° C. for 1 hour. The dried cigarette filter was placed in a crucible and carbonized in a tube furnace. Firstly, nitrogen gas is introduced with a flow rate of 70 sccm. The temperature of the furnace is raised to 840°C-860°C and then kept for 160 minutes at a heating rate of 10-20°C / min. After the furnace cools down to room temperature, the nitrogen gas is turned off. Get the cigarette filter / graphene composite material SEM picture such as figure 2 As shown, it can be clearly seen that there is graphene...

Embodiment 3

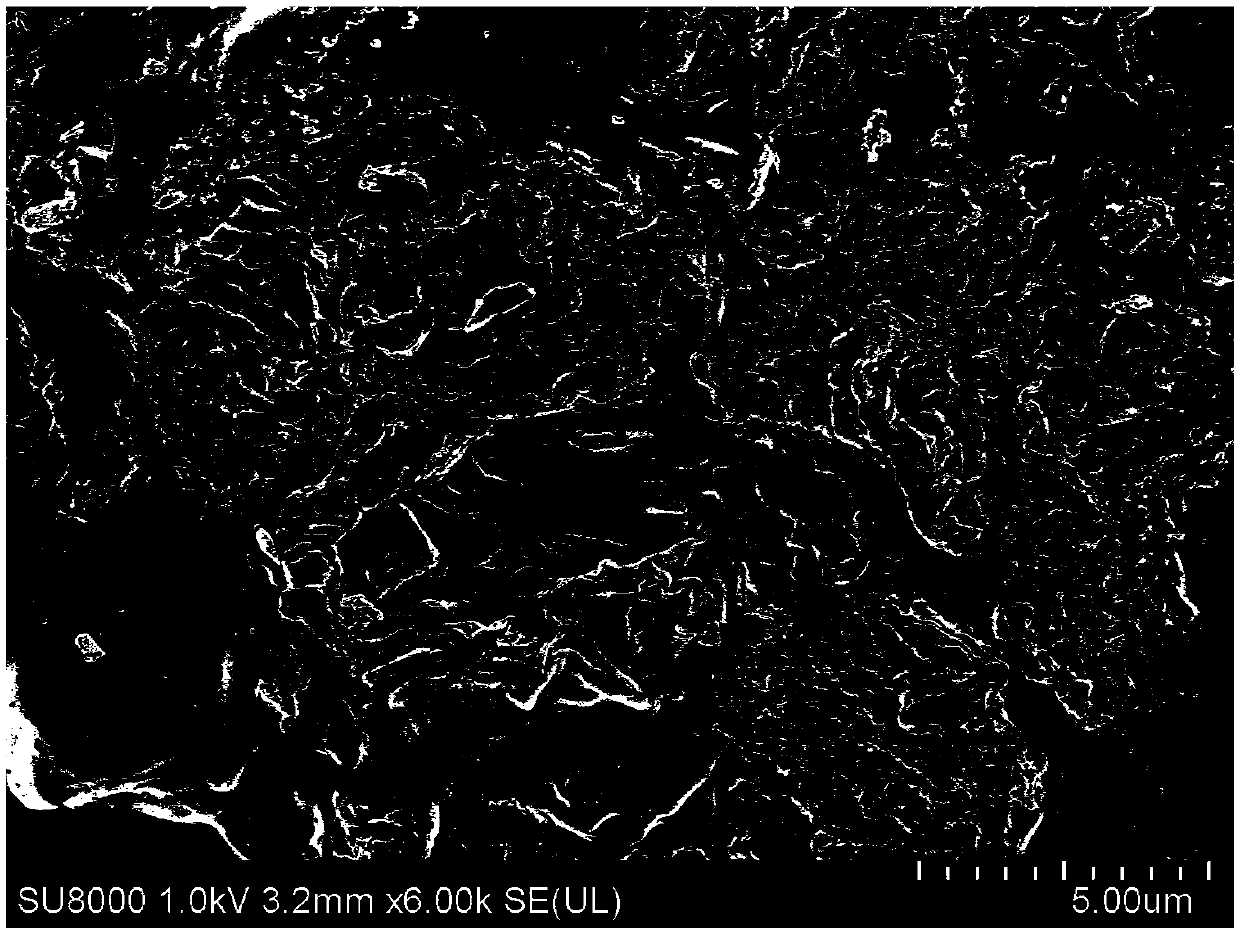

[0036] Disperse 40mg of graphene in 40ml of ethanol and ultrasonically disperse for 30min. According to the mass volume ratio of the cigarette filter tip and the dispersion liquid being 0.05g / ml, soak the waste cigarette filter tip in the ethanol dispersion liquid of graphene for 30s, then remove it and place it on a petri dish for 2min. Subsequent immersion in ethanol dispersion, this process was repeated 20 times. Dry the soaked cigarette filter in an oven at a temperature of 85° C. for 1.5 hours. The dried cigarette filter was placed in a crucible and carbonized in a tube furnace. Firstly, nitrogen gas is introduced with a flow rate of 100 sccm. The temperature of the furnace is raised to 880°C-900°C and then kept for 120 minutes at a heating rate of 10-20°C / min. After the furnace cools down to room temperature, the nitrogen gas is turned off. Get the cigarette filter / graphene composite material SEM picture such as image 3 As shown, it can be seen that there are many do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com