Support set for metal detection corrosive container

A metal detection and corrosion resistance technology, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of no practical application value, complex structure of test piece bracket, interference of corrosion test results, etc., and achieve improvement Metal corrosion efficiency, wide application range, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

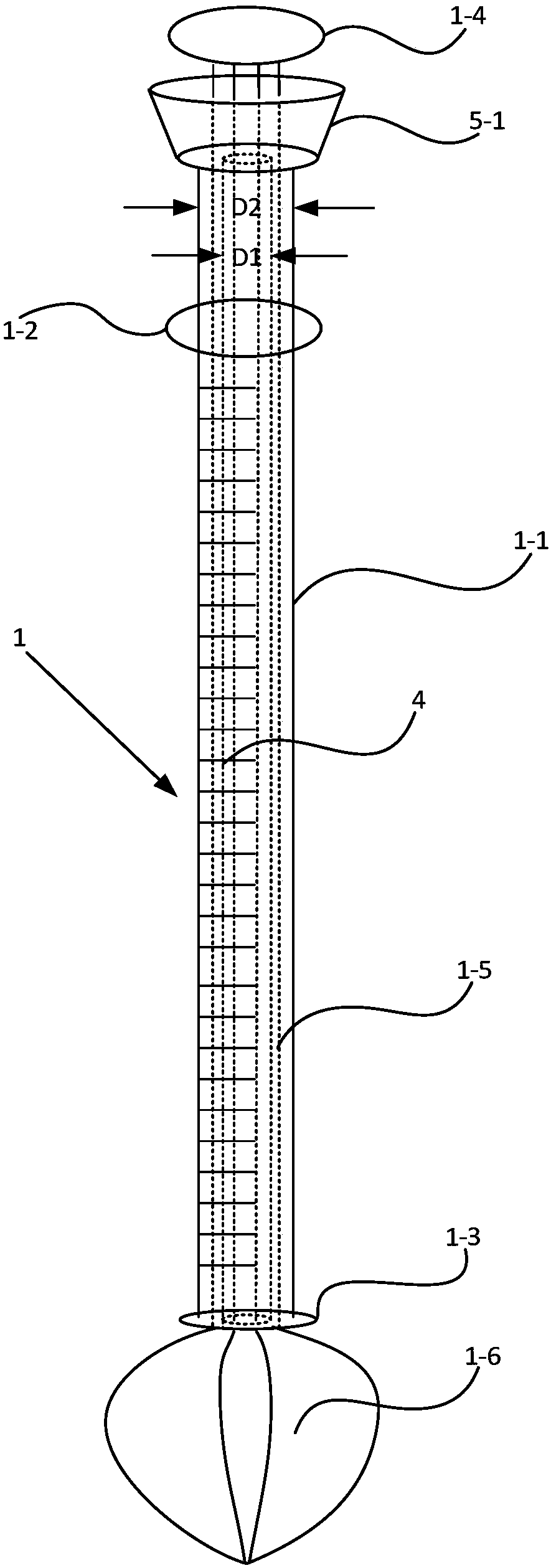

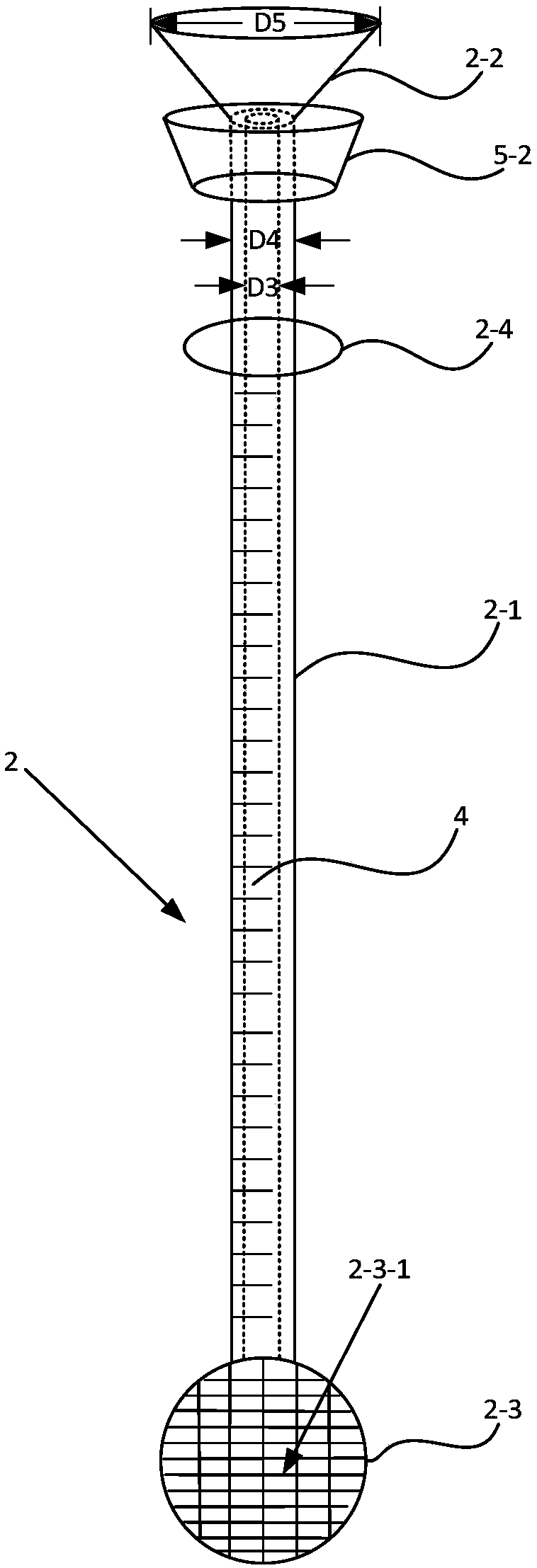

[0041] Embodiment: a metal detection corrosive container bracket set, such as Figure 1 to Figure 3 As shown, it includes a first support 1 for carrying block solids and a second support 2 for carrying particles, the number of the first support can be 3 to 4, and the number of the second support can be 5 to 8;

[0042] The first bracket is provided with a first pipe section 1-1, and the upper end of the first pipe section is provided with a first baffle 1-2 in the circumferential direction. The outer diameter of the first baffle is generally 0.5cm to 0.8cm, depending on the buckle The outer diameter of the first baffle is evaluated by the width of the inner opening. Generally, the outer diameter of the first baffle is greater than the width of the buckle. The lower end of the first pipe section is circumferentially provided with a second baffle 1-3. There are two turnback wires 1-5, each of which is a thread extending from the upper end down through the lower end and then turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com