Waste heat recovery device for oil-electric hybrid vehicle

A technology of waste heat recovery device and oil-electric hybrid power, applied in safety devices, noise reduction devices, exhaust devices, etc., can solve the problems of energy waste, high charging costs, low fuel utilization rate, etc., to reduce charging costs and energy loss The effect of less and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

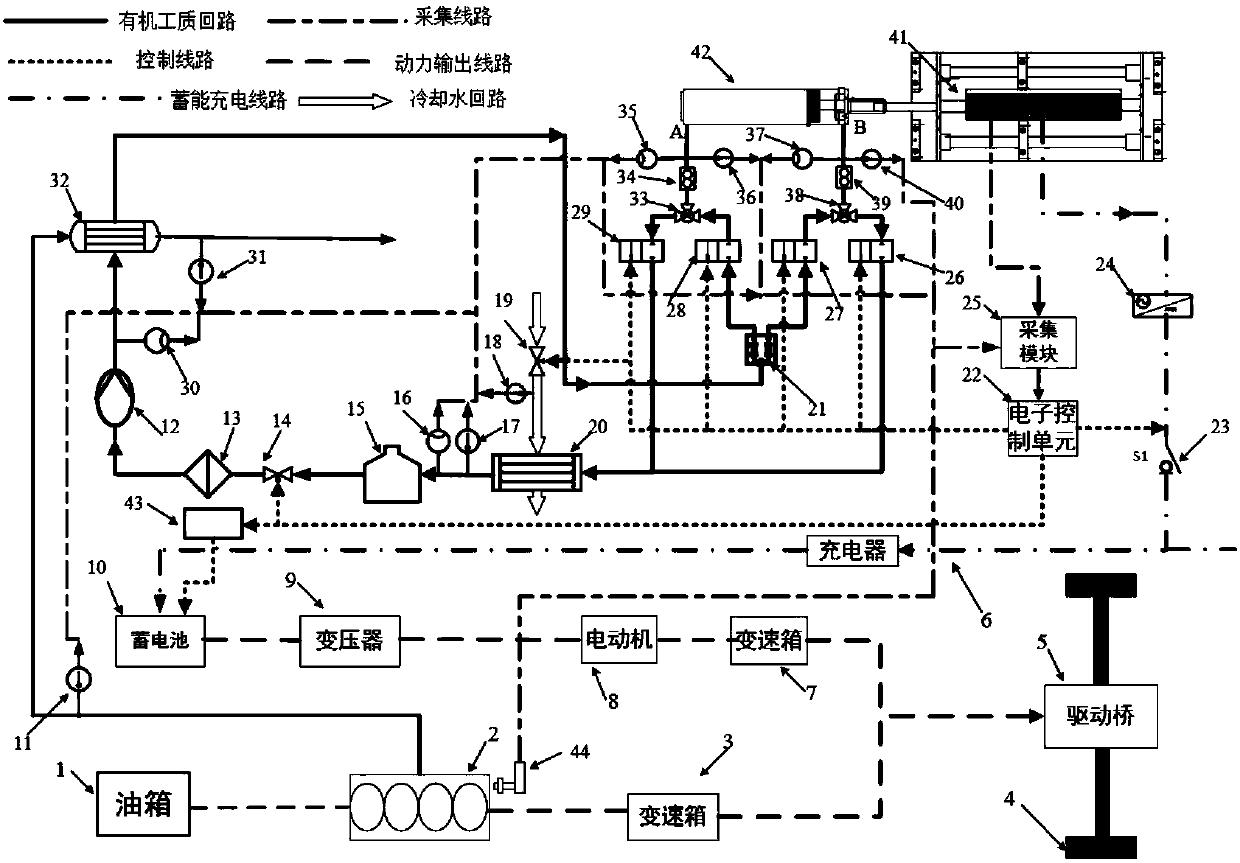

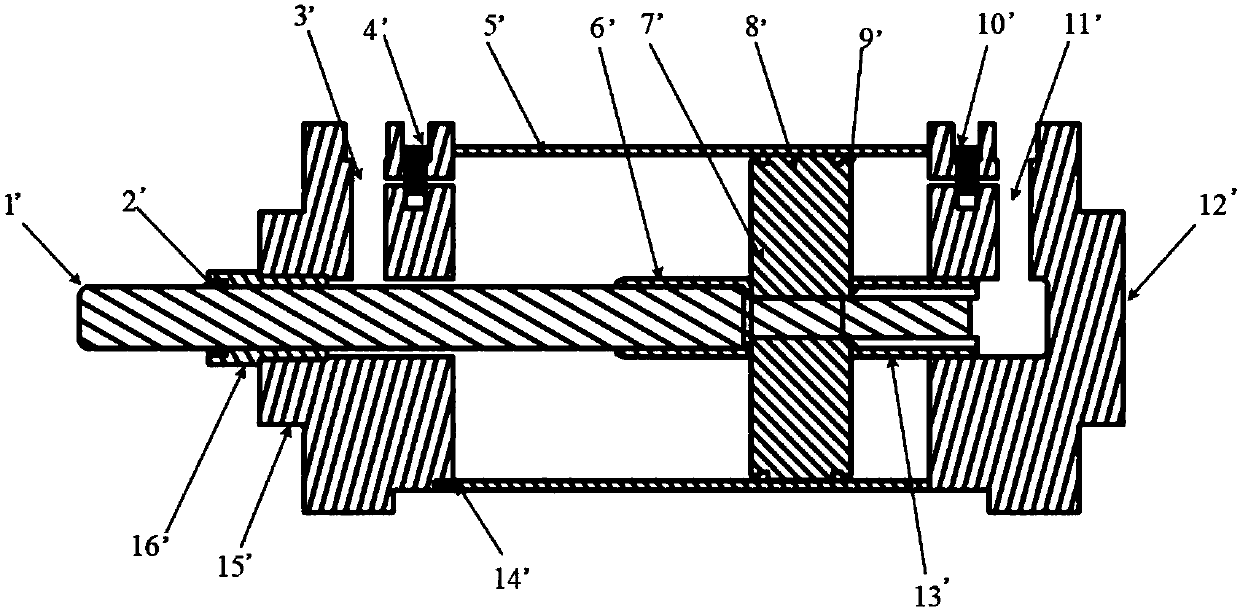

[0028] figure 1 It is a schematic diagram of the waste heat recovery system device of a gasoline-electric hybrid vehicle. The device mainly includes an internal combustion engine exhaust heat recovery system, an energy storage charging system, a power output system, and an acquisition control system. The above internal combustion engine exhaust waste heat recovery system includes internal combustion engine 2, exhaust passage, evaporator 32, flow divider 21, first three-way valve 33, second three-way valve 38, free piston expander 42, condenser 20, storage The liquid tank 15, the first electric valve 14, the working medium filter 13, the working medium pump 12 and the connected working medium pipeline; the above-mentioned energy storage charging system includes a free piston expander 42, a permanent magnet cylindrical linear generator 41 , rectifier 24, switch relay 23, charger 6, storage battery 10 and connecting circuit; The above-mentioned power output system includes drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com