A method for determining the horsepower of fracturing water

A method of determining water horsepower, which is applied in earthwork drilling, wellbore/well components, complex mathematical operations, etc., can solve the problem of large influence of water horsepower determination, difficulty in obtaining coefficients of empirical formulas, and large deviations between calculation results and actual conditions, etc. problem, to achieve the effect of accurate fracturing water horsepower, simple and accurate calculation, and accurate friction calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In order to overcome the difficulties in obtaining the coefficients of the fracturing fluid friction in the prior art using empirical formulas, the calculation results have large deviations from the actual ones, and the technical problems that have a large impact on the determination of water horsepower.

[0033] This embodiment provides a method for determining fracturing water horsepower, which includes the following steps:

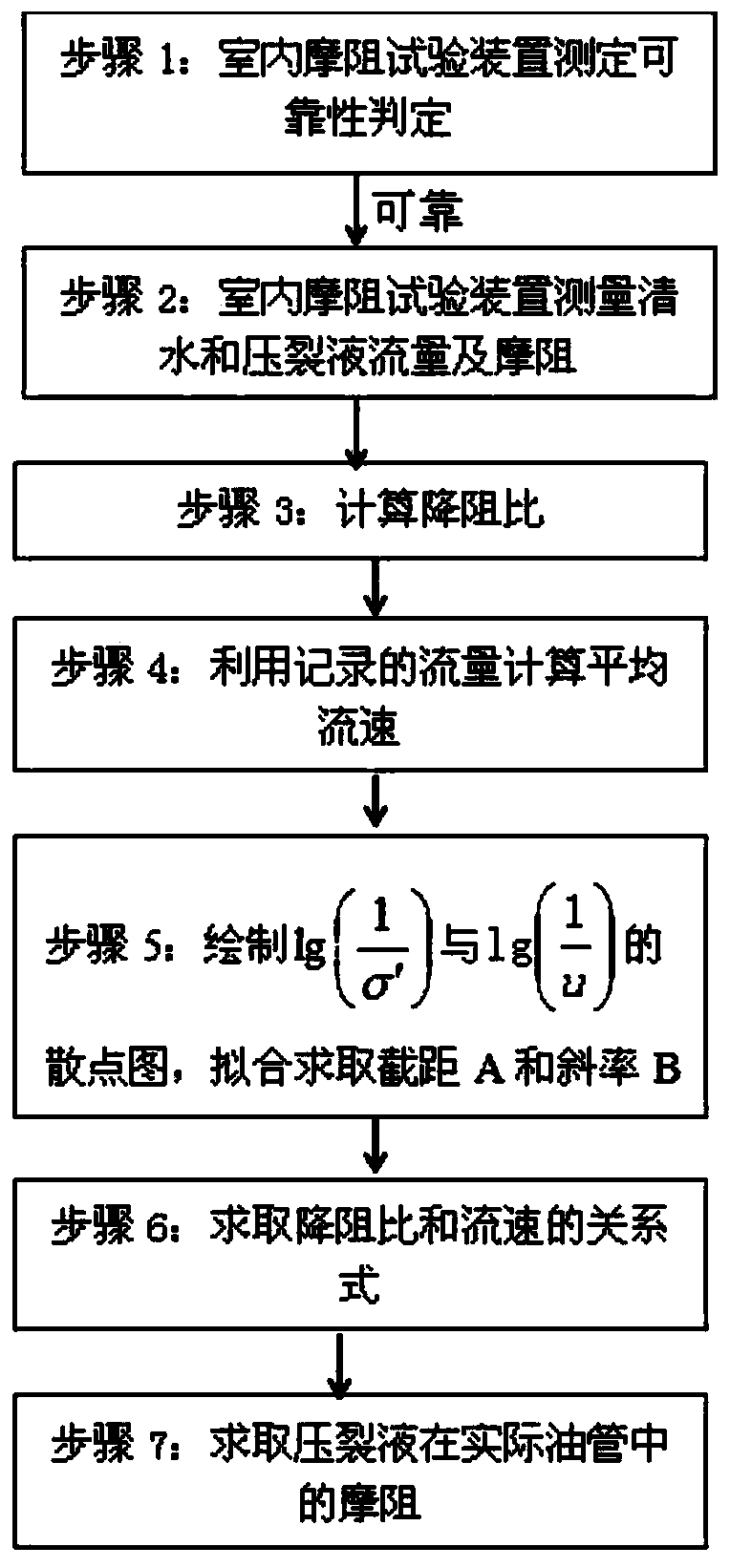

[0034] Step 1) Calculate the frictional resistance of fracturing fluid, the process is as follows (see figure 1 ):

[0035] (1) Verify the accuracy of the test results of the indoor friction test device. The error less than 10% indicates that the indoor friction test device is reliable;

[0036] (2) Configure the fracturing fluid to be measured, and use the indoor friction test device to measure the friction resistance of the fracturing fluid in at least three different pipe string inner diameters and determine the friction resistance of the clean water a...

Embodiment 2

[0046] On the basis of Example 1, this example provides a method for determining the fracturing water horsepower. The accuracy of the test results of the indoor friction test device is verified by the following method: the indoor friction test device is used to determine the Measured value of frictional resistance of clean water under different flow rates of column inner diameter Δp w ′, and the theoretical value of friction resistance of clear water Δp w For comparison, if the error is less than 10%, the indoor friction test device is reliable.

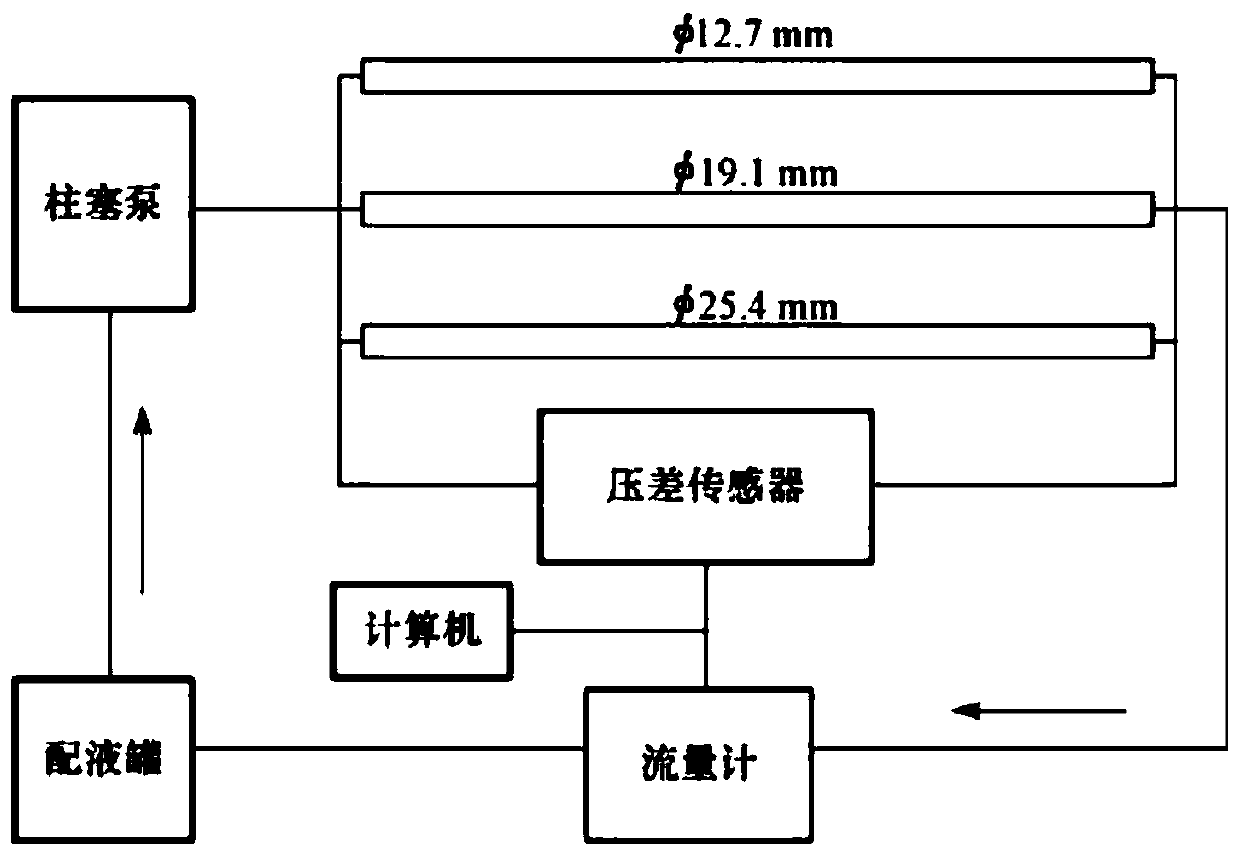

[0047] Wherein, the indoor friction test device includes a liquid distribution tank, a plunger pump, a pipe string and a flow meter which are connected in sequence, a pressure sensor is connected in parallel to the pipe string, and the pressure sensor and the flow meter are both connected to a computer. Such as figure 2 As shown, the outlet of the flow meter is connected with the liquid distribution tank, and the fracturing fluid can be...

Embodiment 3

[0051] On the basis of the foregoing embodiments, the present invention is used to determine the fracturing water horsepower when a guar gum fracturing fluid with a mass concentration of 0.08% is used for fracturing.

[0052] Step 1) Calculate the friction resistance of the guar gum fracturing fluid with a mass concentration of 0.08%:

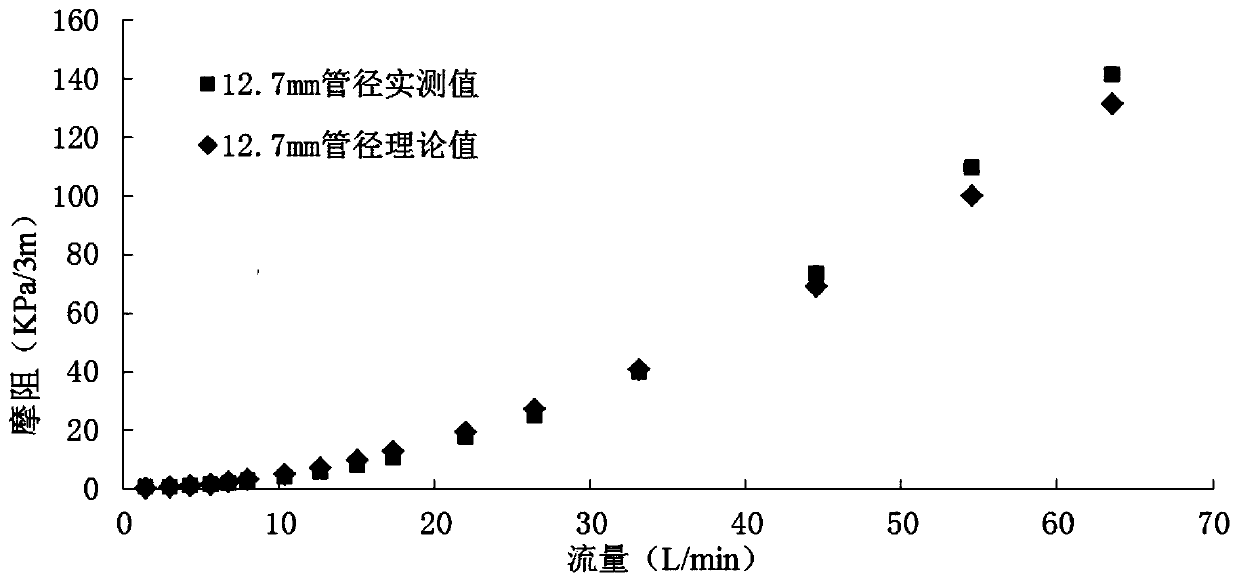

[0053] (1) Adopt figure 2 In the indoor friction test device shown, the temperature rises to the temperature that needs to be tested. First, determine the friction resistance of the clean water under three different pipe column inner diameters D and different flow rates Q, and compare with the theoretical formula calculation results, and draw the clean water under rectangular coordinates. The curve of flow rate, measured value of friction and theoretical value of friction to verify whether the result of equipment test is accurate. If the error is less than 10%, the indoor friction test device is reliable; image 3 , Figure 4 The middle is the compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com