On-line preparation method for hygroscopic yarn in Sirofil composite spinning method

A composite spinning and lofil technology, applied in the field of textile processing, can solve the problems of prolonging the production cycle, increasing the production cost, complicating the production process, etc., and achieving the effect of increased fiber moisture absorption and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

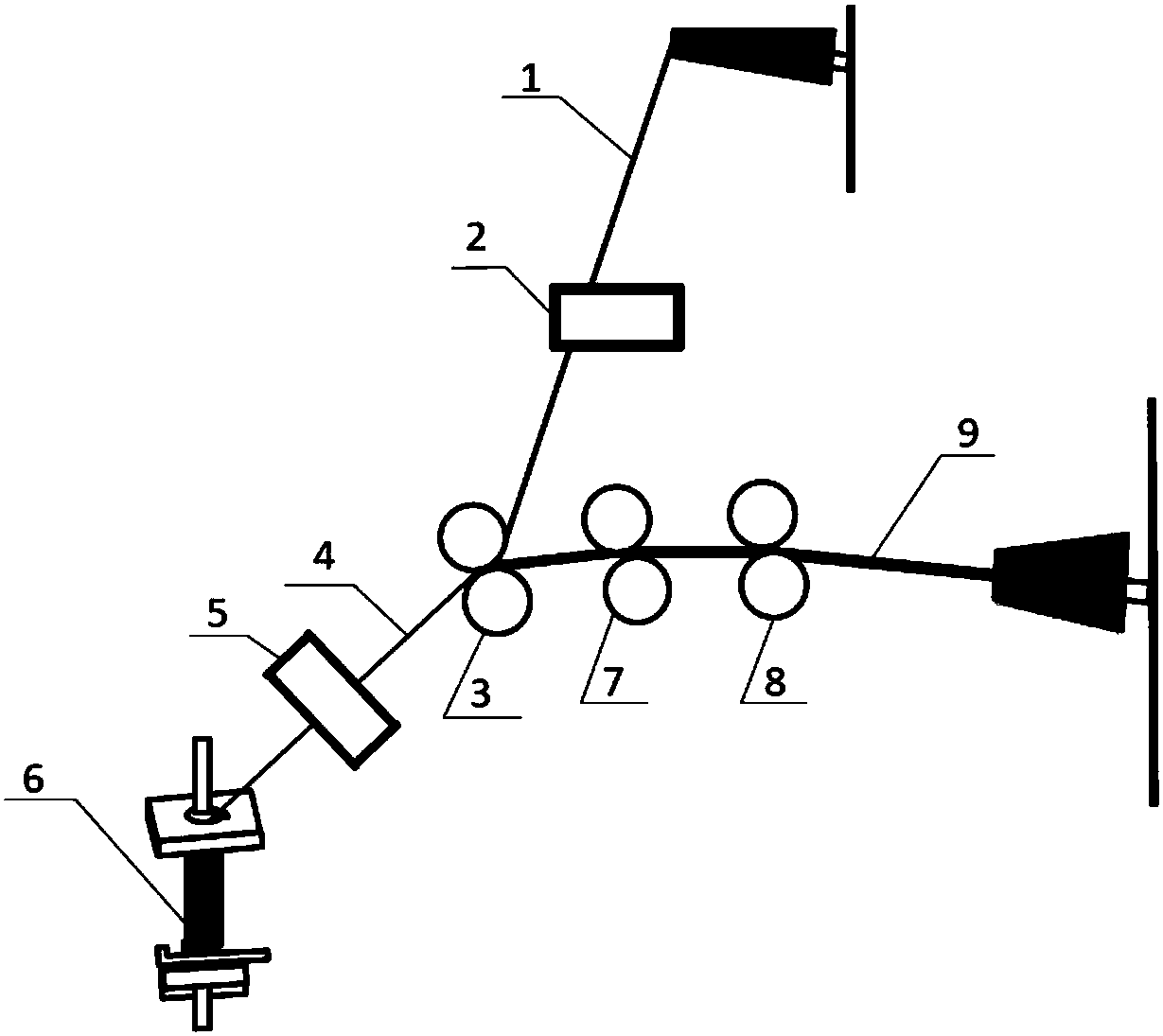

Method used

Image

Examples

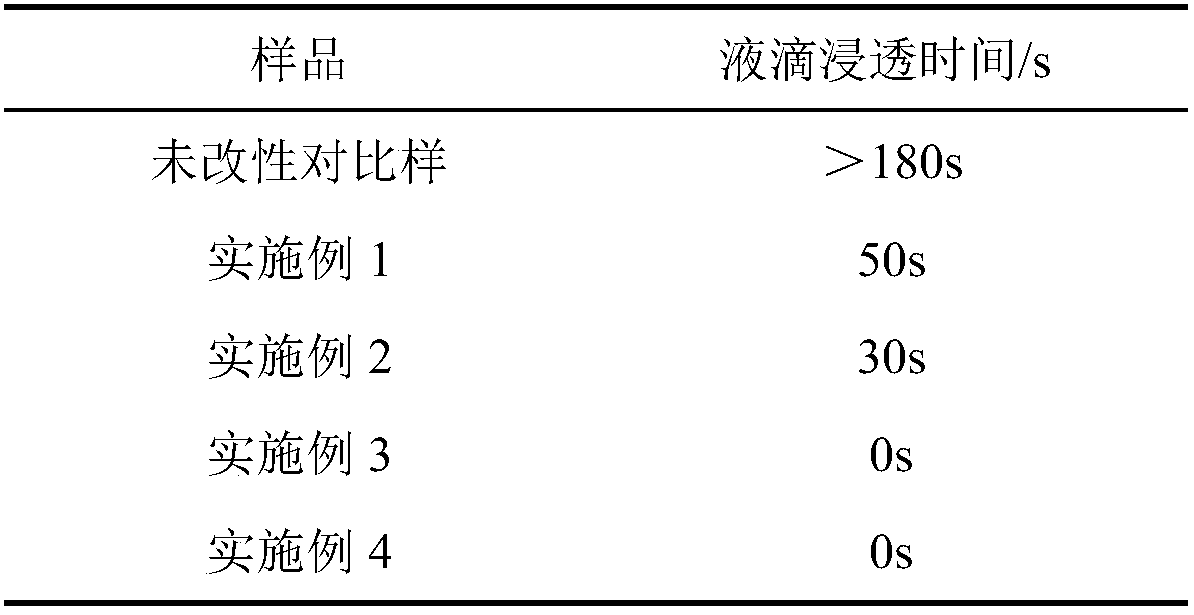

Embodiment 1

[0013] A modification device is set in the running path from the polyester filament to the front roller on the ring spinning frame. The modification device is composed of a flow control device and a wetting device. The flow control device can use a syringe pump, and the wetting device uses a sponge wetting device. A hose is connected between the flow control device and the wetting device. The flow control device adjusts the flow speed of the modified liquid. The wetting device applies a modified liquid to the polyester filaments. The modified liquid is composed of anhydrous ethanol and fatty alcohol polyoxyethylene. Ether is mixed, and the mass ratio of absolute ethanol and fatty alcohol polyoxyethylene ether is 97:3. The flow rate of the flow control device in the modification device is 40 drops / min. A drying device is installed between the front roller on the ring spinning frame and the spinning tube. The drying device can use infrared radiation heaters, and the polyester fila...

Embodiment 2

[0015] A modification device is set in the running path from the polyester filament to the front roller on the ring spinning frame. The modification device is composed of a flow control device and a wetting device. The flow control device can be a peristaltic pump, and the wetting device can be a sponge wetting device. A hose is connected between the flow control device and the wetting device. The flow control device adjusts the flow speed of the modified liquid. The wetting device applies a modified liquid to the polyester filaments. The modified liquid is composed of anhydrous ethanol and fatty alcohol polyoxyethylene. A mixture of ether, the mass ratio of anhydrous ethanol and fatty alcohol polyoxyethylene ether is 95:5. The flow rate of the flow control device in the modification device is 50 drops / min. A drying device is installed between the front roller of the ring spinning frame and the spinning tube. The drying device can be a resistance heater. The polyester filament i...

Embodiment 3

[0017] A modification device is set in the running path from the polyester filament to the front roller on the ring spinning frame. The modification device is composed of a flow control device and a wetting device. The flow control device can use a syringe pump, and the wetting device uses a sponge wetting device. A hose is connected between the flow control device and the wetting device. The flow control device adjusts the flow speed of the modified liquid. The wetting device applies a modified liquid to the polyester filaments. The modified liquid is composed of anhydrous ethanol and fatty alcohol polyoxyethylene. A mixture of ether, the mass ratio of anhydrous ethanol and fatty alcohol polyoxyethylene ether is 93:7. The flow rate of the flow control device in the modification device is 60 drops / min. A drying device is installed between the front roller of the ring spinning frame and the spinning tube. The drying device can use infrared radiation heaters. The polyester filamen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com