A startup and shutdown process of biomass gasifier coupled with coal-fired units

A technology for coal-fired units and gasifiers, which is applied in the gasification process, the manufacture of combustible gas, and the petroleum industry. The effect of safe shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

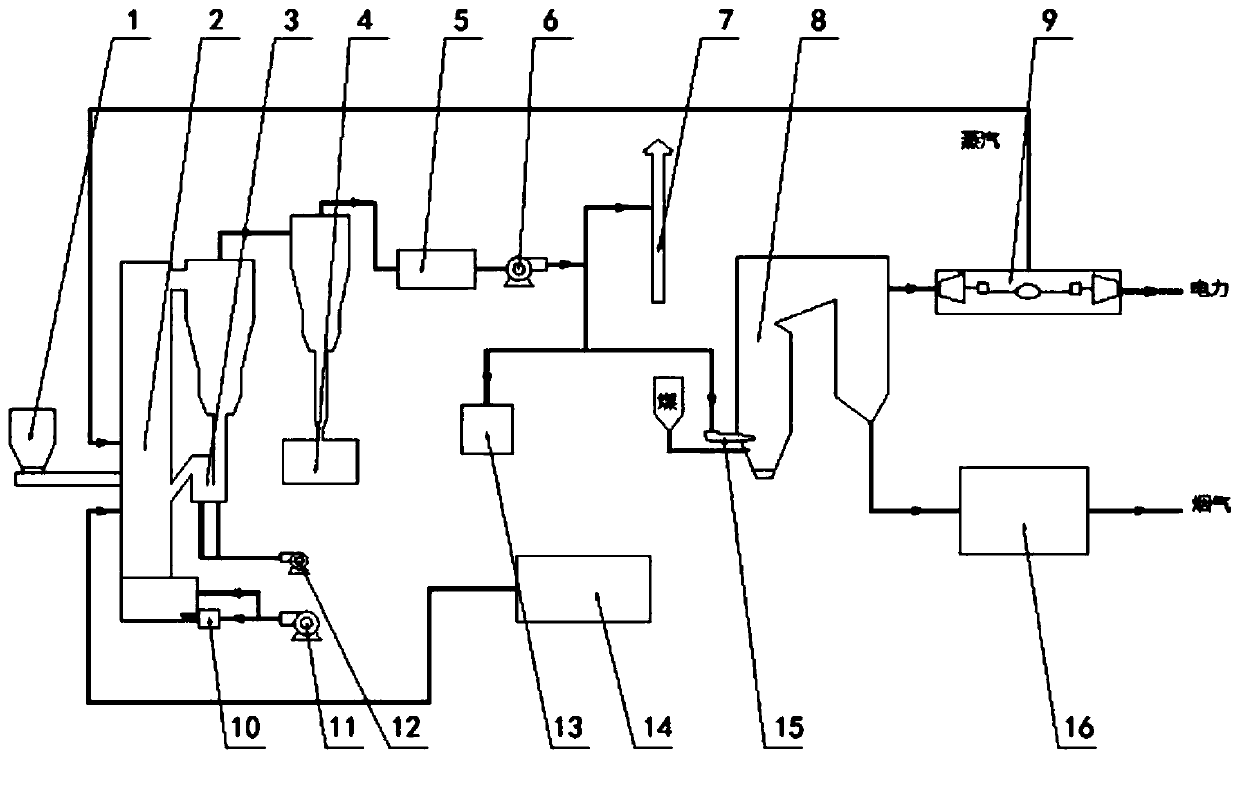

Image

Examples

Embodiment 1

[0059] Taking rice husk raw material as an example, a start-up and shutdown process of a biomass gasifier coupled with a coal-fired unit includes the following steps:

[0060] (1) Furnace start-up process

[0061] A. Ignition start

[0062] A1. Put the gas into the pipeline of the boiler system, start the air induction device and the blower device, adjust the pressure of the feeding port to keep it at about -200-0Pa, and keep the pressure constant during the furnace start-up process;

[0063] A2. Start the return device, adjust the flow rate of the fluidized medium and the return medium until the bed material in the return device flows stably;

[0064] A3. Start the ignition burner, observe the combustion situation of the ignition burner, monitor the change of oxygen amount, and keep the combustion completely stable;

[0065] A4. Keep the burner burning stably, adjust the amount of oil and air in the burner, monitor the temperature rise in the dense phase area, and control t...

Embodiment 2

[0095] Taking wheat straw molding fuel raw materials as an example, a start-up and shutdown process of a biomass gasifier coupled with a coal-fired unit includes the following steps:

[0096] (1) Furnace start-up process

[0097] A. Ignition start

[0098] A1. Put the gas into the pipeline of the boiler system, start the air induction device and the blower device, adjust the pressure of the feeding port to keep it at about -100 to 50Pa, and keep the pressure constant during the process of starting the furnace;

[0099] A2. Start the return device, adjust the air flow rate of the fluidized medium and the return medium to the stable flow of the bed material in the return device;

[0100] A3. Start the ignition burner, observe the combustion situation of the ignition burner, monitor the change of oxygen amount, and keep the combustion completely stable;

[0101] A4. Keep the burner burning stably, adjust the amount of oil and air in the burner, monitor the temperature rise in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com