Anti-corrosion rubber capable of isolating ultrasonic waves

A kind of anti-corrosion rubber and ultrasonic technology, applied in the field of anti-corrosion rubber, to achieve excellent ultrasonic absorption performance and good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

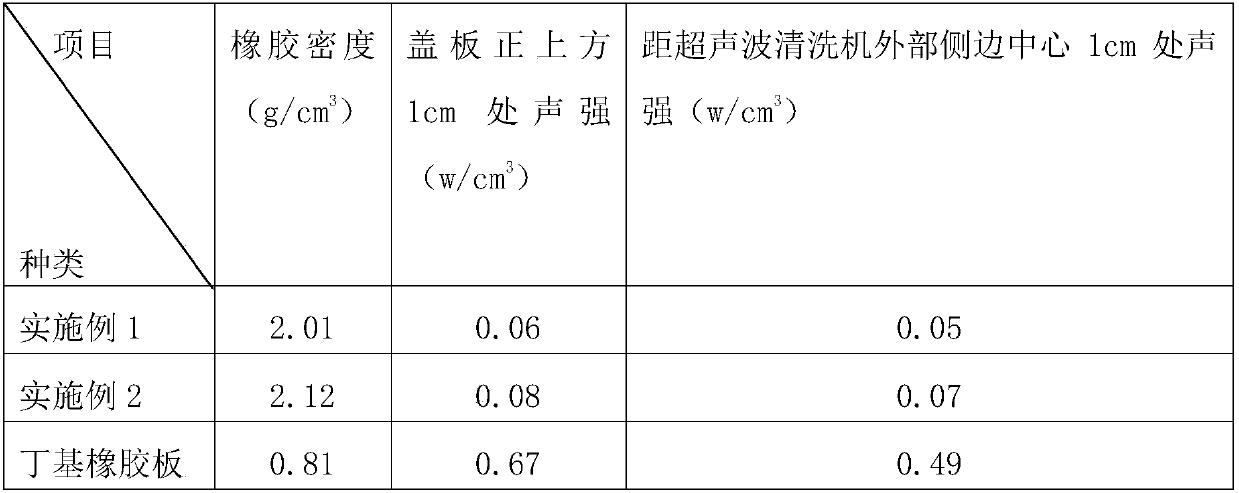

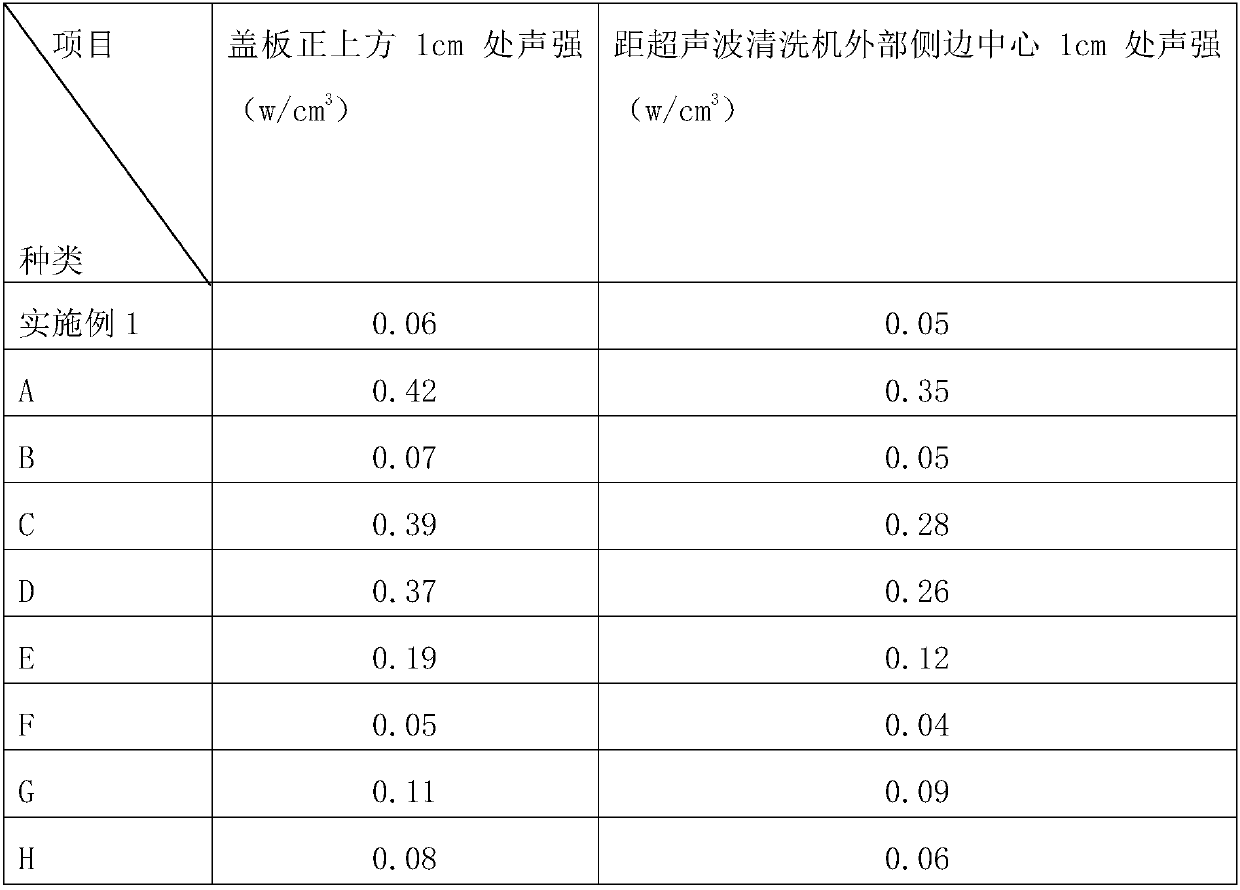

Examples

Embodiment 1

[0020] Graphene oxide was prepared by the Hummers method. Cool 4L of 98% concentrated sulfuric acid to 0°C, add 20g of graphene, 10g of sodium nitrate and 6g of potassium permanganate, stir magnetically in a water bath at 0°C for 5 hours, heat up to 35°C, and react 30min, add 1L of deionized water, rapidly raise the temperature to 98°C, keep for 15min, stop heating, use 40°C deionized water to make up to 10L, add 1L of 30% hydrogen peroxide and 7L of 5% hydrochloric acid for pickling, magnetically stir for 5min, centrifuge and wash (7000r Remove the supernatant after centrifuging at 10 min at 10 min, stir for 1 min, add deionized water and centrifuge at 7000 r / min for 10 min, repeat this 3 times or more) until the pH is close to neutral to obtain graphite oxide, ultrasonic 2 h, make it fully peeled off, A graphene oxide suspension was prepared.

[0021] The hollow glass microspheres were leached in a 3.0 mg / ml graphene oxide suspension for 5 minutes, and then dried at 120° C. ...

Embodiment 2

[0036] Graphene oxide was prepared by the Hummers method. Cool 4L of 98% concentrated sulfuric acid to 0°C, add 20g of graphene, 10g of sodium nitrate and 6g of potassium permanganate, stir magnetically in a water bath at 0°C for 5 hours, heat up to 35°C, and react 30min, add 1L of deionized water, rapidly raise the temperature to 98°C, keep for 15min, stop heating, use 40°C deionized water to make up to 10L, add 1L of 30% hydrogen peroxide and 7L of 5% hydrochloric acid for pickling, magnetically stir for 5min, centrifuge and wash (7000r Remove the supernatant after centrifuging at 10 min at 10 min, stir for 1 min, add deionized water and centrifuge at 7000 r / min for 10 min, repeat this 3 times or more) until the pH is close to neutral to obtain graphite oxide, ultrasonic 2 h, make it fully peeled off, A graphene oxide suspension was prepared.

[0037] The hollow glass microspheres were leached in a 3.5 mg / ml graphene oxide suspension for 5 minutes, and then dried at 120° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com