Method for extracting ursolic acid from Cynomorium songaricum by using eutectic solvent/salt aqueous two-phase system

A low eutectic solvent, two-phase system technology, applied in the direction of steroids, organic chemistry, etc., to achieve the effect of short phase separation time, good biocompatibility, easy to scale up and industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

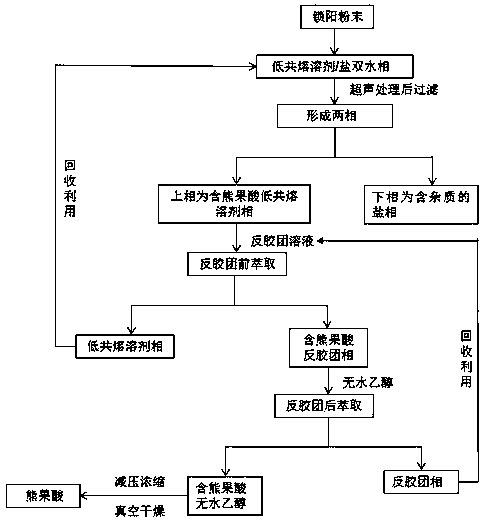

Image

Examples

Embodiment 1

[0030] (1) Formation of deep eutectic solvent / salt two-phase system: K 2 HPO 4 After adding a certain amount of distilled water to fully dissolve, add a deep eutectic solvent composed of choline chloride and urea (molar ratio 1:1), and form a two-phase aqueous system after mixing. In the aqueous two-phase system, the mass percentage of the deep eutectic solvent is 25%, K 2 HPO 4 The quality score of is 38%.

[0031] (2) Ultrasonic-assisted extraction: Cynomorium powder is added to the two-phase system according to the solid-liquid ratio of 1:50 (g / g), the ultrasonic power is 300W, the pulse working mode is ultrasonic 2s, intermittent 2s, ultrasonic at 30°C Treat for 20min. Filter, and the filtrate is allowed to stand for 1h to form two phases, the upper phase is the deep eutectic solvent phase containing ursolic acid; the lower phase is the impurity-containing K 2 HPO 4 Mutually;

[0032] (3) Secondary aqueous two-phase extraction: In the above-mentioned deep eutectic s...

Embodiment 2

[0036] (1) Formation of deep eutectic solvent / salt two-phase system: K 2HPO 4 After adding a certain amount of distilled water to fully dissolve, add a deep eutectic solvent composed of choline chloride and 1.3-butanediol (molar ratio 1:2), and form an aqueous two-phase system after mixing. In the aqueous two-phase system, the mass fraction of the deep eutectic solvent is 28%, K 2 HPO 4 The mass fraction is 35%.

[0037] (2) Ultrasonic-assisted deep eutectic solvent / salt two-phase extraction: Cynomorium powder is added to the two-phase system at a solid-to-liquid ratio of 1:100 (g / g), the ultrasonic power is 500W, and the pulse working mode is Sonicate for 2s, intermittently for 2s, and sonicate at 30°C for 10min. After filtering, the filtrate was allowed to stand for 1.5 hours to form two phases, the upper phase being a deep eutectic solvent phase containing ursolic acid; the lower phase being a salt solution containing impurities.

[0038] (3) Secondary aqueous two-phas...

Embodiment 3

[0042] (1) Formation of deep eutectic solvent / salt two-phase system: K 2 HPO 4 After adding a certain amount of distilled water to fully dissolve, add a deep eutectic solvent composed of choline chloride and glycerin (molar ratio 1:1), and form a two-phase aqueous system after mixing. In the aqueous two-phase system, the mass fraction of the deep eutectic solvent is 30%, K 2 HPO 4 The quality fraction is 40%.

[0043] (2) Ultrasonic-assisted deep eutectic solvent / salt two-phase extraction: Cynomorium powder is added to the two-phase system at a solid-to-liquid ratio of 1:75 (g / g), the ultrasonic power is 350W, and the pulse working mode is Sonicate for 2s, intermittently for 2s, and sonicate at 40°C for 25min. After filtration, after the filtrate was allowed to stand for 1 h, two phases were formed, the upper phase was a deep eutectic solvent phase containing ursolic acid; the lower phase was K 2 HPO 4 solution.

[0044] (3) Secondary aqueous two-phase extraction: In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com