High-efficiency waste sulfuric acid concentration method

A waste sulfuric acid, high-efficiency technology, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve the problems of inability to improve the purity of sulfuric acid, equipment loss rate, etc., to achieve high concentration and purification efficiency, improve purity , the effect of increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

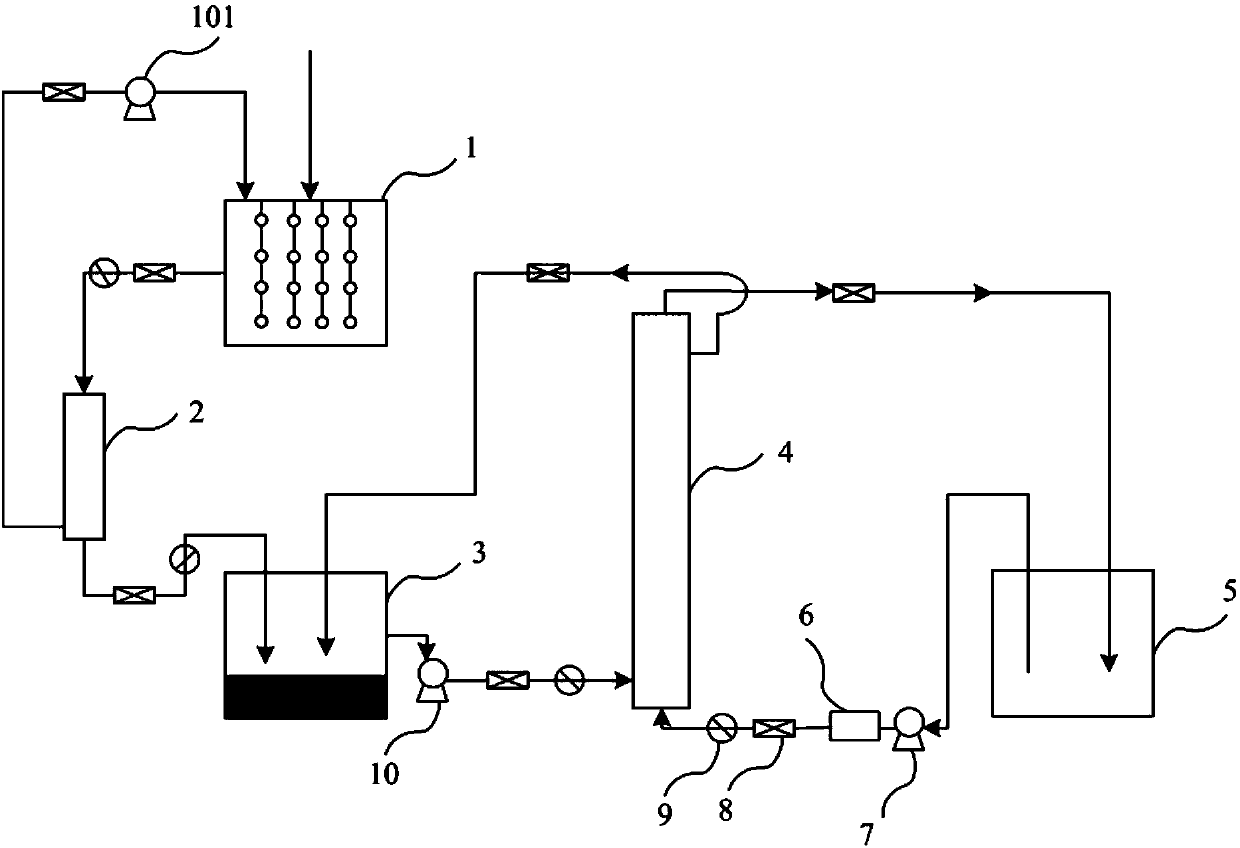

[0028] A method for concentrating high-efficiency waste sulfuric acid, comprising the following steps:

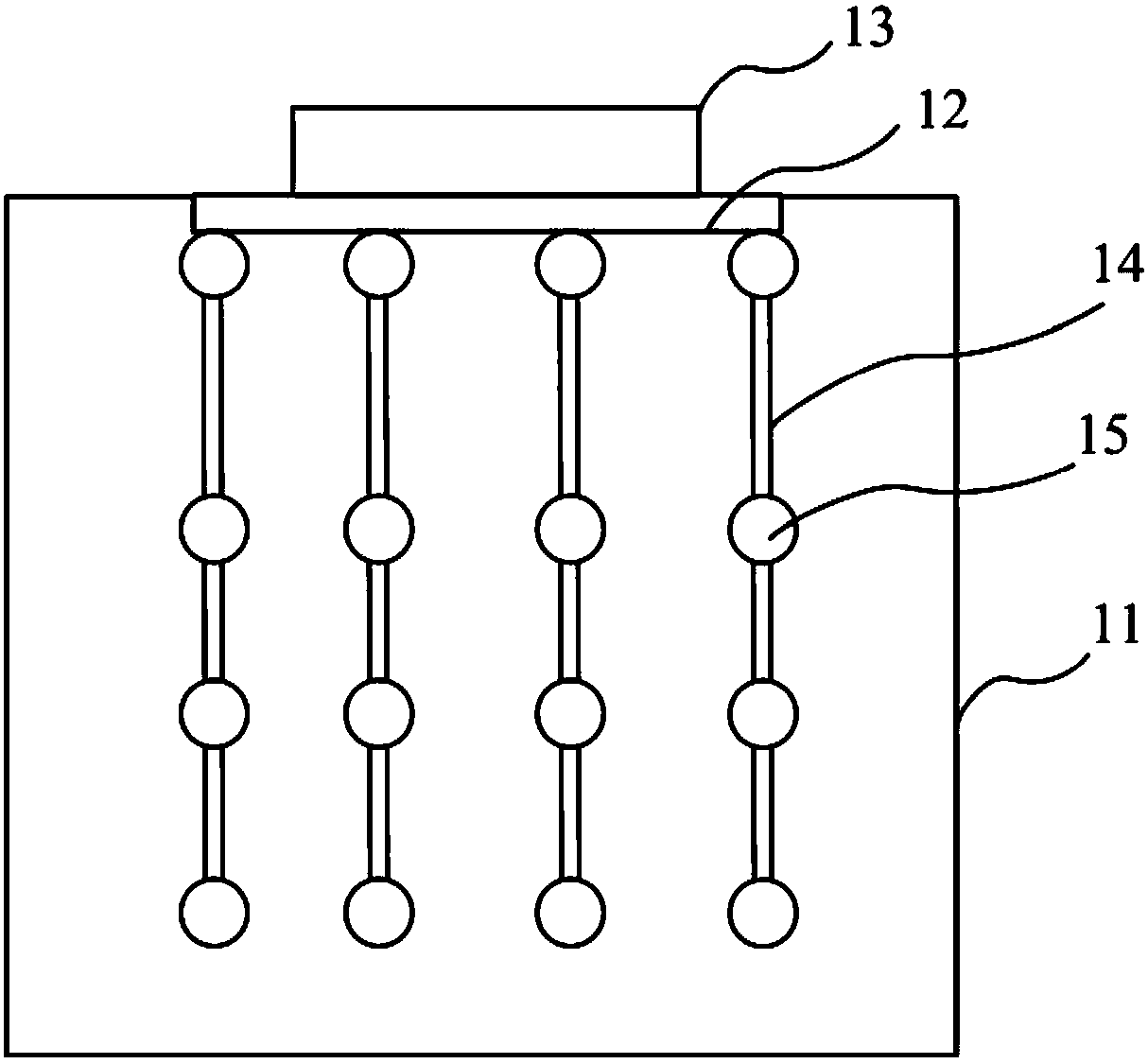

[0029] S1, the waste sulfuric acid is subjected to precipitation reaction in the precipitation tank 1: first place the waste sulfuric acid to be treated in the precipitation tank 1, and add polyaluminum ferric sulfate. The dosage of polyaluminum ferric sulfate is 0.01 per liter of waste sulfuric acid. -0.05g, turn on the rotating motor 13, stir for 5 minutes after the addition, and flocculate Fe 3+ 、Cr 3+ 、Cr 6+ After the metal cations are filtered by the filter 2, the filtered water is obtained;

[0030] Before heating and concentrating, the waste sulfuric acid flows through the liquid circuit for precipitating waste sulfuric acid (the two water flow switches on the liquid circuit for precipitating waste sulfuric acid are turned on, and the rest of the water flow switches are closed), and the metal cations in the waste sulfuric acid are fully recovered by circulation twi...

Embodiment 2

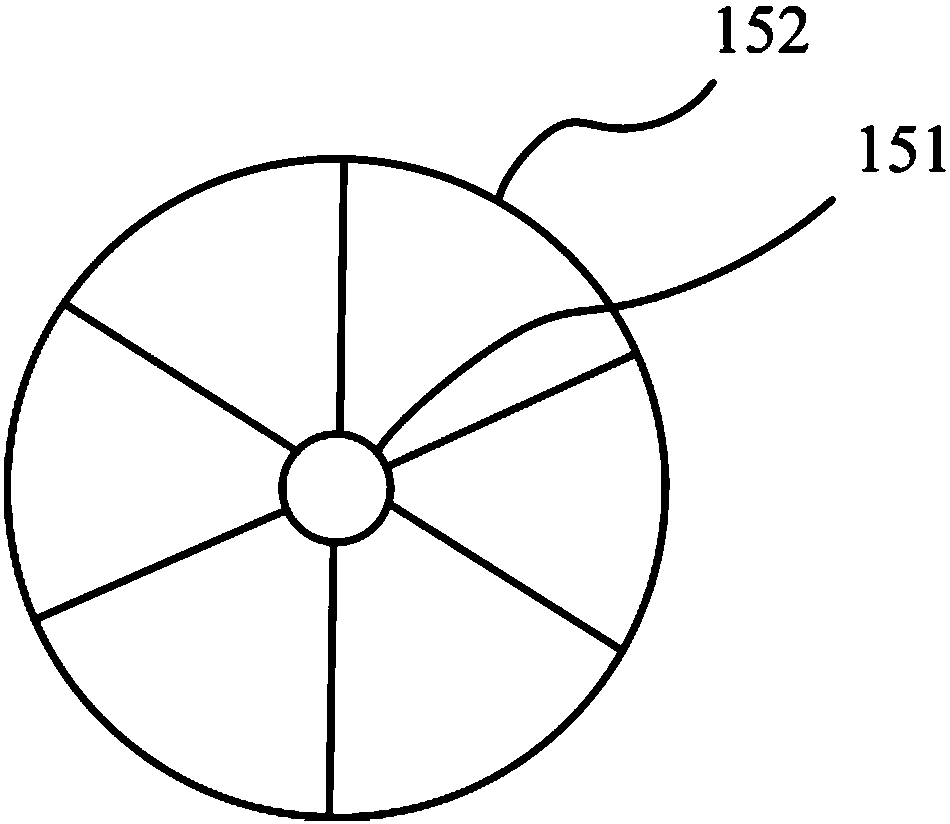

[0038] A method for concentrating high-efficiency waste sulfuric acid, the operation steps are basically the same as those in Example 1, the difference is that the process is heated to 60°C in S2. Wherein in S1, the shell wall of the porous spherical shell 152 is provided with a plurality of openings with a diameter of 10-20 microns; the diameter of the flow hole on the wall of the central connecting pipe 151 is 1.5-3 microns; The hole diameter of the water outlet on the stirring tube 14 is 4-5 microns; in S3, the hole diameter of the hollow fiber membrane is 0.2-0.5 microns.

Embodiment 3

[0040] A high-efficiency method for concentrating waste sulfuric acid, the operation steps are basically the same as those in Example 1, the difference is that the process is heated to 65°C in S2.

[0041] Taking Examples 1-3 as examples below, the sulfuric acid enrichment and purification effect of the present invention is illustrated.

[0042] Get the pickling waste liquid sample (numbered as A) and the chromium electroplating wastewater sample (numbered as B) of the factory, process according to the method of embodiment 1-3 respectively, the concentrated sulfuric acid in the heating tank 3, then detect before and after treatment Fe in samples A and B 3+ 、Cr 6+ 、Cr 3+ 、Cu 2+ , Zn 2+ 、Al 3+ , Pb 2+ content, the results are shown in Table 1. The results in Table 1 show that after two rounds of purification and three rounds of concentration in wastewater samples A and B, the concentration of metal ions was significantly reduced, and Fe 3+ Reduced by more than 88%, Cr 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com