Metal wires and manufacturing and on-line cooling method thereof

A manufacturing method and technology of metal wire, which is applied in the manufacture of metal wire and on-line cooling, and in the field of metal wire, can solve the problems of insufficient processing allowance, distortion and deformation of the receiving plate, and insufficient hardness of the surface, so that it is not easily deformed by heat or failure, high heat resistance and deformation resistance, excellent performance of spring steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

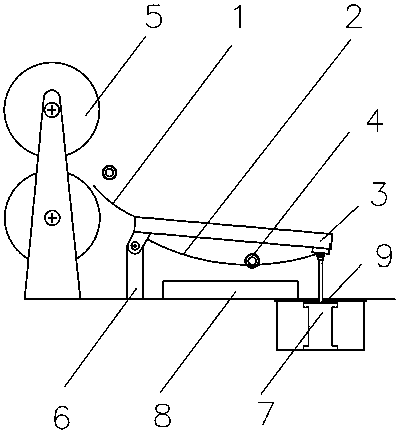

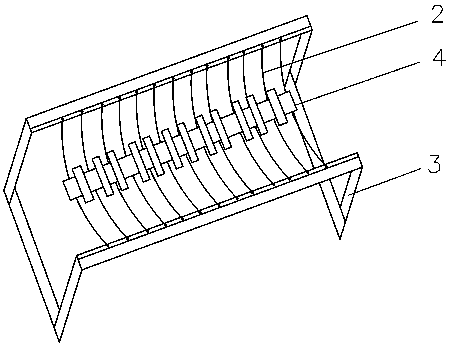

[0028] see below figure 2 , figure 2 It shows that the blanking device of the present invention has used the metal wires arranged at intervals, and the structure of the wires arranged at intervals is completely different from the receiving plate of the traditional technology, and the metal wires arranged at intervals have played the following roles at least: first, the cam The contact area between the shaft 4 and the metal wire is small, and the metal wire is smooth throughout, which avoids collisions and bumps with the camshaft. Secondly, the sliding speed of the camshaft 4 on the wire is slowed down, avoiding flying out of the connection due to the inertia of the drop. Part 2 risk.

[0029] exist figure 1 Among them, the material receiving part 2 adopts the metal wire structure arranged at intervals, which achieves higher production efficiency through a simple structure.

[0030] As an indispensable part of the present invention, the material selection and manufacture a...

Embodiment 2

[0037] In this embodiment, the material and manufacturing process of the metal wire are further optimized.

[0038] The Ni-based alloy with a weight percentage content of Fe between 10% and 16%, specifically selects 14% Fe content by weight percentage, and also includes the following components (weight percentage): 15% Cr, 0.5% Al, 3 % Mo, 0.2% W, 7% Co, 0.5% C.

[0039] The deformation rate of each section of the wire drawing process is 30%, and the finished product is heat-treated at a constant temperature of 720°C for 12 hours.

Embodiment 3

[0041] The difference between this embodiment and embodiment 2 is:

[0042] The Ni-based alloy with a weight percentage content of Fe between 10% and 16%, the Fe weight percentage content is specifically selected as 16%, including the following components: 20% Cr, 2% Al, 2.5% Mo, 0.9 % W, 5% Co, 0.8% C.

[0043] The deformation rate of each section of the wire drawing process is 35%, and the finished product is heat-treated at a constant temperature of 750°C for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com