Main board impurity removing device for computer hardware production

A technology for computer hardware and motherboards, which is applied in the field of motherboard impurity removal devices for computer hardware production, which can solve problems such as reducing the quality of computers and motherboards, and achieve the effects of preventing fine impurities from dispersing, protecting the health of the body, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

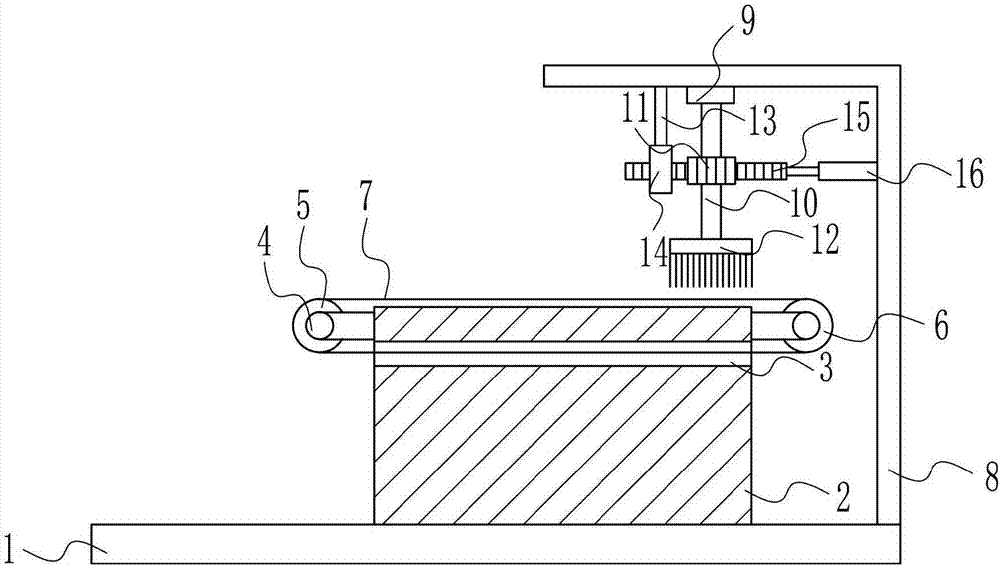

Embodiment 1

[0036] A motherboard impurity removal device for computer hardware production, such as Figure 1-6 As shown, it includes a base plate 1, a workbench 2, a first motor 4, a first pulley 5, a second pulley 6, a flat belt 7, a support plate 8, a bearing seat 9, a rotating shaft 10, a gear 11, a brush 12, a vertical The rod 13, the guide sleeve 14, the rack 15 and the telescopic device 16, the top of the bottom plate 1 is provided with a workbench 2, the upper part of the workbench 2 is provided with an opening 3 horizontally, and the left side of the workbench 2 is provided with a first motor 4, The output shaft of the first motor 4 is connected with a first pulley 5 through a coupling, and a second pulley 6 is installed on the upper left side of the table 2 by bolting, and the second pulley 6 is connected with the first pulley 5. There is a flat belt 7, the flat belt 7 passes through the opening 3, the top of the bottom plate 1 is provided with a support plate 8, the middle of th...

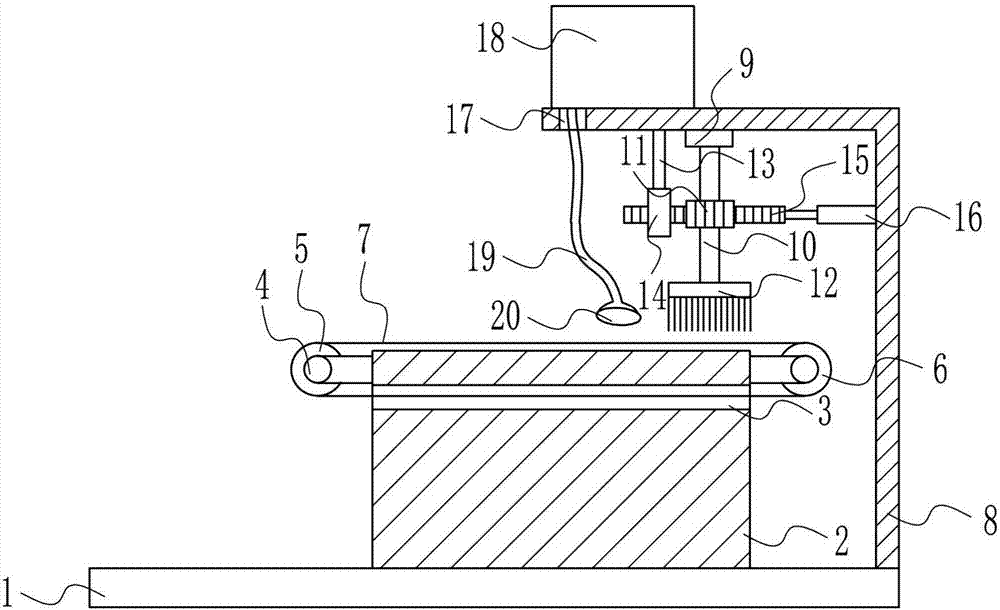

Embodiment 2

[0038] A motherboard impurity removal device for computer hardware production, such as Figure 1-6 As shown, it includes a base plate 1, a workbench 2, a first motor 4, a first pulley 5, a second pulley 6, a flat belt 7, a support plate 8, a bearing seat 9, a rotating shaft 10, a gear 11, a brush 12, a vertical The rod 13, the guide sleeve 14, the rack 15 and the telescopic device 16, the top of the bottom plate 1 is provided with a workbench 2, the upper part of the workbench 2 is provided with an opening 3 horizontally, and the left side of the workbench 2 is provided with a first motor 4, The output shaft of the first motor 4 is connected with a first pulley 5 through a coupling, and a second pulley 6 is installed on the upper left side of the table 2 by bolting, and the second pulley 6 is connected with the first pulley 5. There is a flat belt 7, the flat belt 7 passes through the opening 3, the top of the bottom plate 1 is provided with a support plate 8, the middle of th...

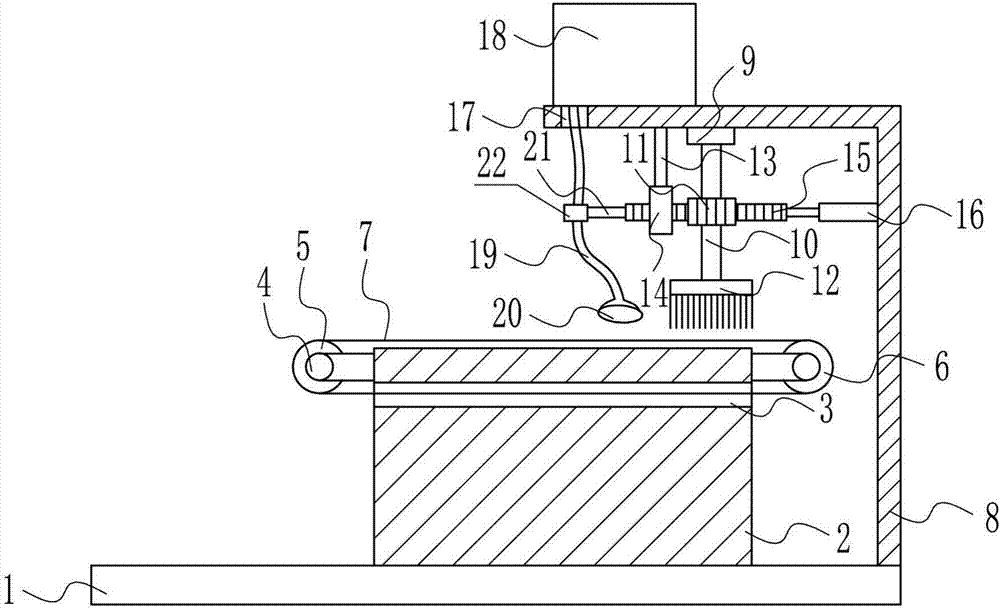

Embodiment 3

[0041] A motherboard impurity removal device for computer hardware production, such as Figure 1-6 As shown, it includes a base plate 1, a workbench 2, a first motor 4, a first pulley 5, a second pulley 6, a flat belt 7, a support plate 8, a bearing seat 9, a rotating shaft 10, a gear 11, a brush 12, a vertical The rod 13, the guide sleeve 14, the rack 15 and the telescopic device 16, the top of the bottom plate 1 is provided with a workbench 2, the upper part of the workbench 2 is provided with an opening 3 horizontally, and the left side of the workbench 2 is provided with a first motor 4, The output shaft of the first motor 4 is connected with a first pulley 5 through a coupling, and a second pulley 6 is installed on the upper left side of the table 2 by bolting, and the second pulley 6 is connected with the first pulley 5. There is a flat belt 7, the flat belt 7 passes through the opening 3, the top of the bottom plate 1 is provided with a support plate 8, the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com