Surface molded 3D (Three Dimensional) printing method and system

A 3D printing and surface forming technology, applied in the field of rapid prototyping, can solve the problems of expensive introduction, slow response, unsatisfactory equipment manufacturing precision, etc., achieve high efficiency and reduce equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

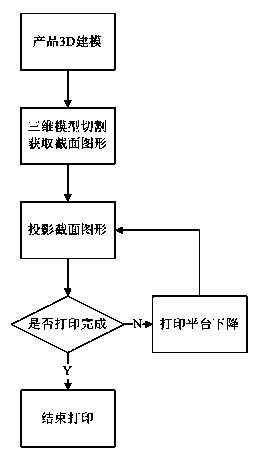

[0036] Such as figure 1 As shown, the surface forming 3D printing method of this embodiment includes the following steps:

[0037] S1. Carry out 3D modeling of the product to be printed, and divide the built 3D model into multi-layer cross-sectional graphics. 3D modeling can be made by various existing commercial software. Taking CAD as an example, the 3D model can be made through CAD and stored in the form of STL file, and then slice the STL file to obtain multi-layer interface graphics. The number of cut surfaces is related to the size of the product to be printed, and it is preferable to control the printing thickness of each layer within the range of 10-100 microns to ensure printing accuracy.

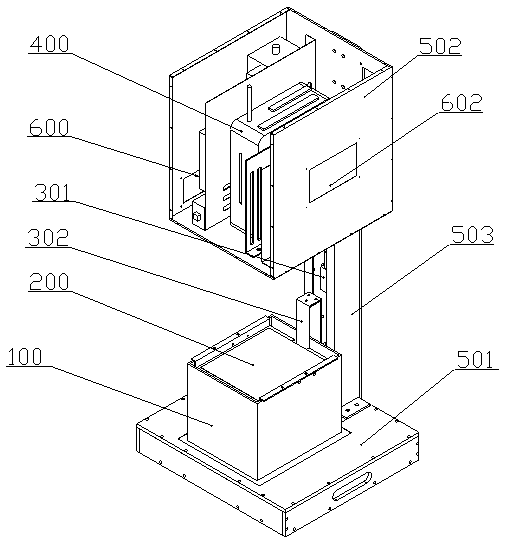

[0038] S2. Install a predetermined amount of liquid light-curing material in the liquid tank, place the printing platform in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com