A manual mechanical cleaning device

A cleaning device and manual mechanical technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as uneconomical use, and achieve high work efficiency, convenient work, and low input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

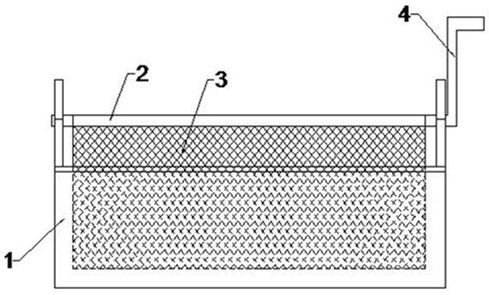

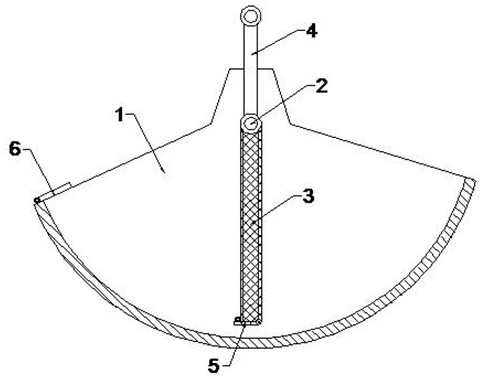

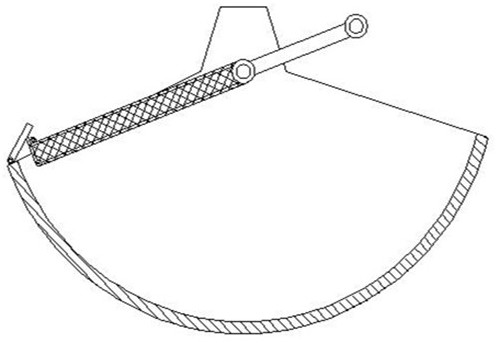

[0022] like figure 1 , figure 2 , Image 6 As shown, a manual mechanical cleaning device includes a cylinder body 1 and a material holding device arranged inside the cylinder body 1; wherein the central axis of the cylinder body 1 is arranged along the horizontal direction, and the section along the vertical direction is fan-shaped, and the fan-shaped end surface The angle formed by the structure is 110°~145°; the material holding device includes a rotating shaft 2 fixed on both sides of the upper end of the cylinder body 1, a material net 3 arranged below the rotating shaft 2 and a handle 4 fixed at the end of the rotating shaft 2; The axis coincides with the central axis of the cylinder body 1, and the upper end has a feed port arranged along the central axis direction and communicated with the material net 3; the distance between the lower end surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com