Thermoelectric conversion device

A thermoelectric conversion device and thermoelectric conversion technology, which are applied in the manufacture/processing of thermoelectric devices, electrical components, thermoelectric devices using only Peltier or Seebeck effect, etc., and can solve the problems of interface fatigue, complex manufacturing process, performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

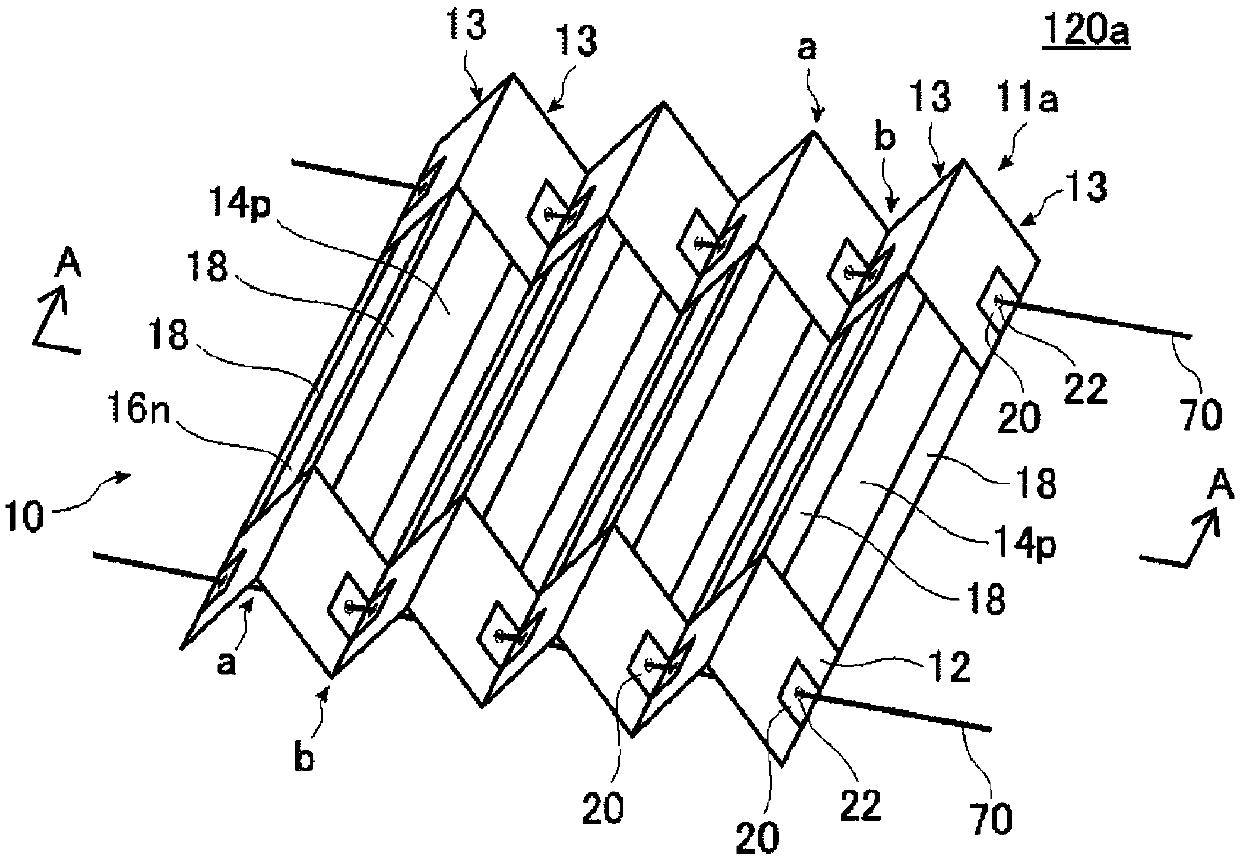

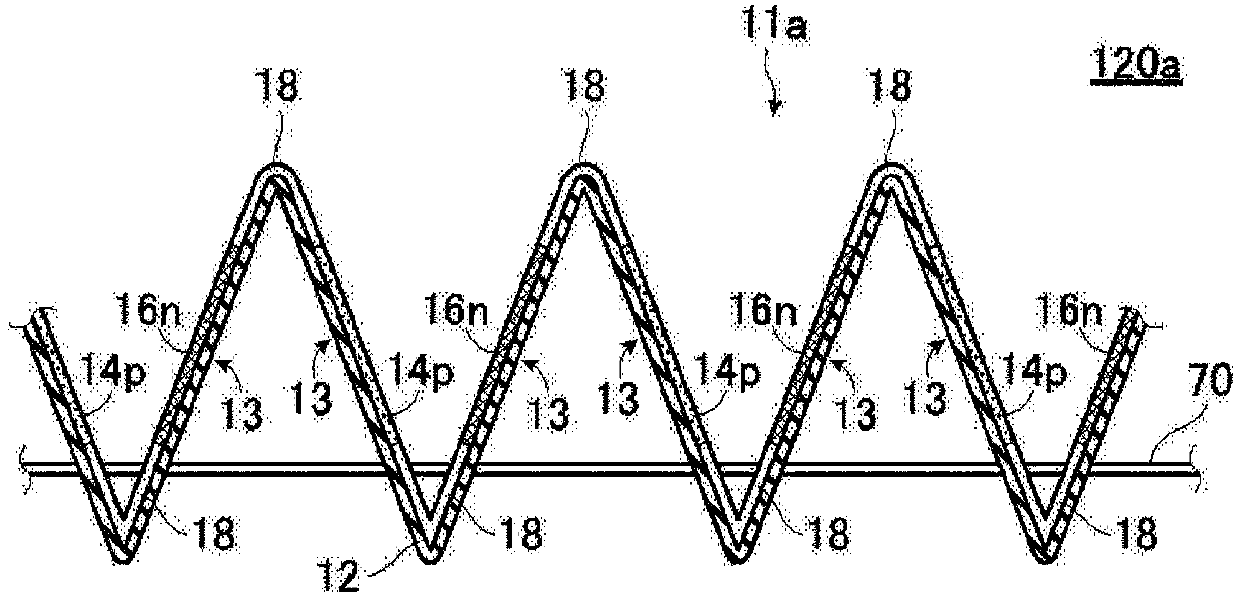

[0063] Hereinafter, the thermoelectric conversion device of the present invention will be described in detail based on preferred embodiments shown in the drawings.

[0064] In addition, in the following, "-" which shows a numerical range includes the numerical value described on both sides. For example, ε is a numerical value α to a numerical value β, which means that the range of ε is a range including the numerical value α and the numerical value β, and expressed in mathematical notation, it is α≤ε≤β.

[0065] Regarding the angle, unless otherwise specified, it means that the difference from the exact angle is within a range of less than 5°. The difference from the exact angle is preferably less than 4°, more preferably less than 3°.

[0066] In addition, "same" and "same" are defined as including an error range generally allowed in the technical field. In addition, "the whole surface" and the like include not only the case of 100%, but also the error range generally allow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com