Self-supporting disordered graphite carbon/carbon nanotube composite spring and preparation method and application thereof

A carbon nanotube composite, carbon nanotube fiber technology, applied in spring/shock absorber manufacturing, springs, low internal friction springs, etc. Good stability, simple operation, good self-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

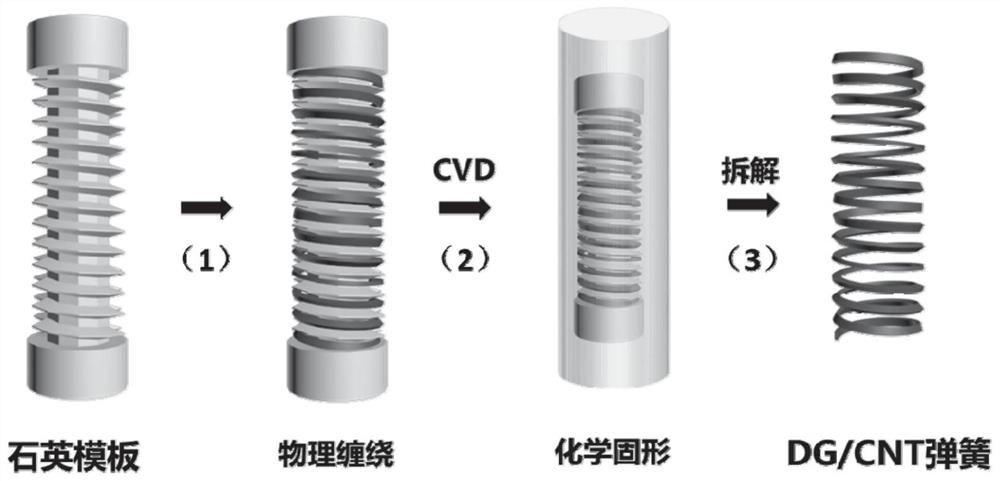

[0030] One aspect of the embodiments of the present invention provides a method for preparing a self-supporting disordered graphitic carbon / carbon nanotube composite spring, which includes:

[0031] Provide carbon nanotube fibers;

[0032] Fixing the carbon nanotube fibers on a template with a helical structure by physical winding;

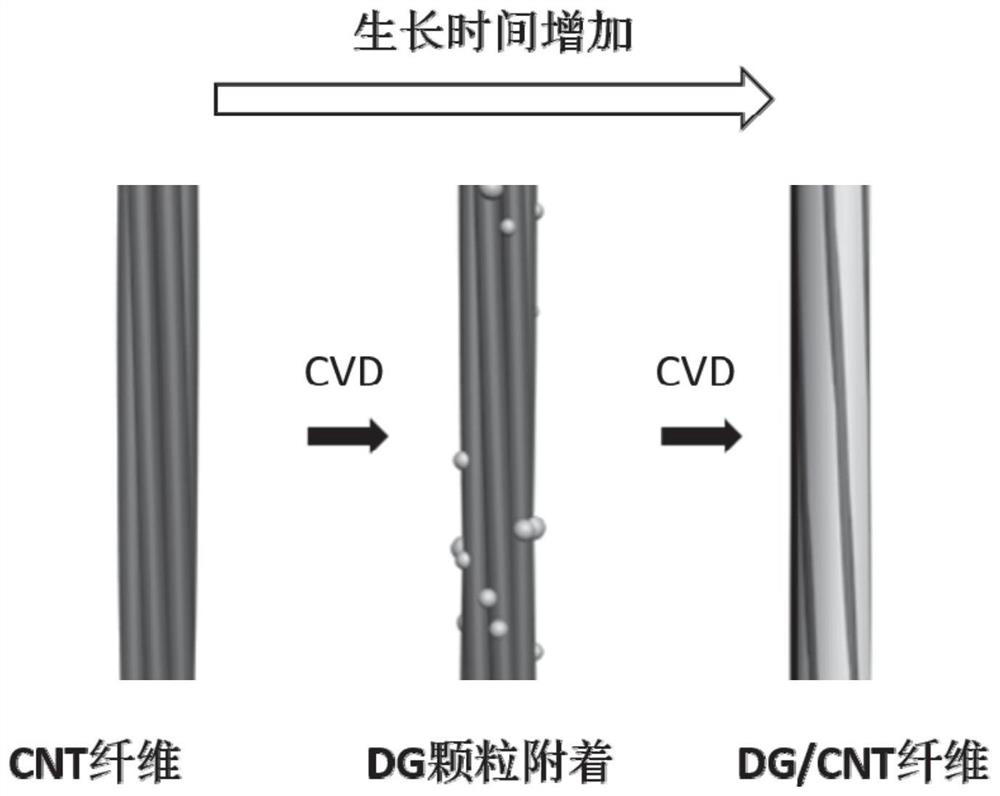

[0033] And, adopt the chemical vapor deposition method to carry out the deposition of amorphous graphitic carbon to the obtained helical carbon nanotube fiber wound on the template, thereby obtain the self-supporting disordered graphitic carbon / carbon nanotube composite spring with helical spring structure ( DG / CNT spring).

[0034] Further, the thread and pitch of the formwork with thread structure in the present invention can be designed in different sizes according to the application scenarios, and the dimensional parameters of the prepared composite spring are exactly the same as those of the formwork.

[0035] In some more specific embodime...

Embodiment 1

[0064] (1) Winding the CNT fiber on a quartz stud with thread, the thread diameter of the quartz stud is 5mm, and the pitch is 1mm;

[0065] (2) placing the fixed carbon nanotube fiber together with the quartz stud in the reaction chamber of the chemical vapor deposition equipment;

[0066] (3) Introduce methane and hydrogen into the reaction chamber, so that methane begins to pyrolyze at 1000°C to generate disordered graphitic carbon, which is deposited on the surface of the carbon nanotube fiber at the same time, and the deposition time is 30 minutes to obtain DG / CNT fiber composite materials;

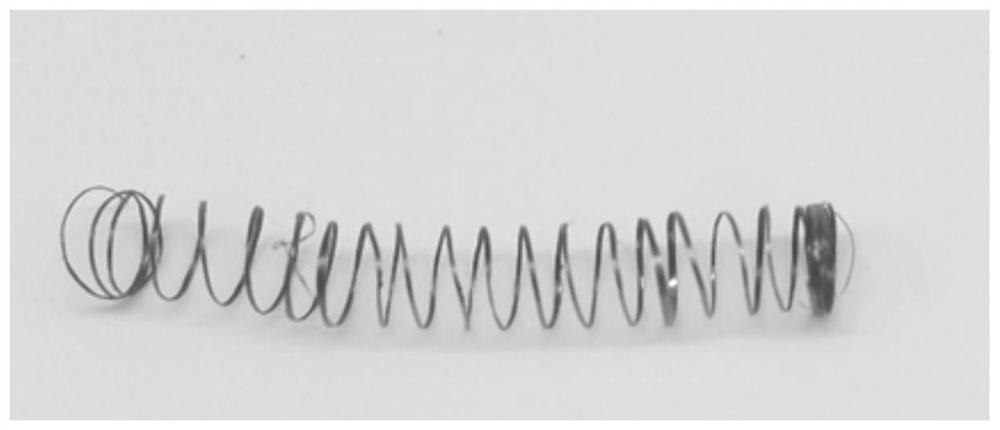

[0067] (4) After the chemical vapor deposition is completed, the DG / CNT fiber is disassembled from the quartz stud to obtain a self-supporting disordered graphite carbon / carbon nanotube composite spring (DG / CNT spring), and the prepared DG / CNT spring Macro picture such as image 3 As shown, the topography of the microstructure is shown in Figure 4 and Figure 5 shown.

[0068] ...

Embodiment 2

[0073] (1) Winding the CNT fiber on a quartz stud with thread, the thread diameter of the quartz stud is 1.5mm, and the pitch is 0.5mm;

[0074] (2) placing the fixed carbon nanotube fiber together with the quartz stud in the reaction chamber of the chemical vapor deposition equipment;

[0075] (3) Introduce methane and hydrogen into the reaction chamber, so that methane begins to pyrolyze at 1000°C to generate disordered graphitic carbon, which is deposited on the surface of the carbon nanotube fiber at the same time, and the deposition time is 30 minutes to obtain DG / CNT fiber composite materials;

[0076] (4) After the chemical vapor deposition is completed, the DG / CNT fiber is disassembled from the quartz stud to obtain a self-supporting disordered graphite carbon / carbon nanotube composite spring (DG / CNT spring), and the prepared DG / CNT spring pictures such as Figure 7 As shown, the topography of the microstructure and Figure 4 and Figure 5 unanimous.

[0077] Perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com