Diamond substrate and method for producing diamond substrate

A diamond and substrate technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve problems such as inability to manufacture diamond substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

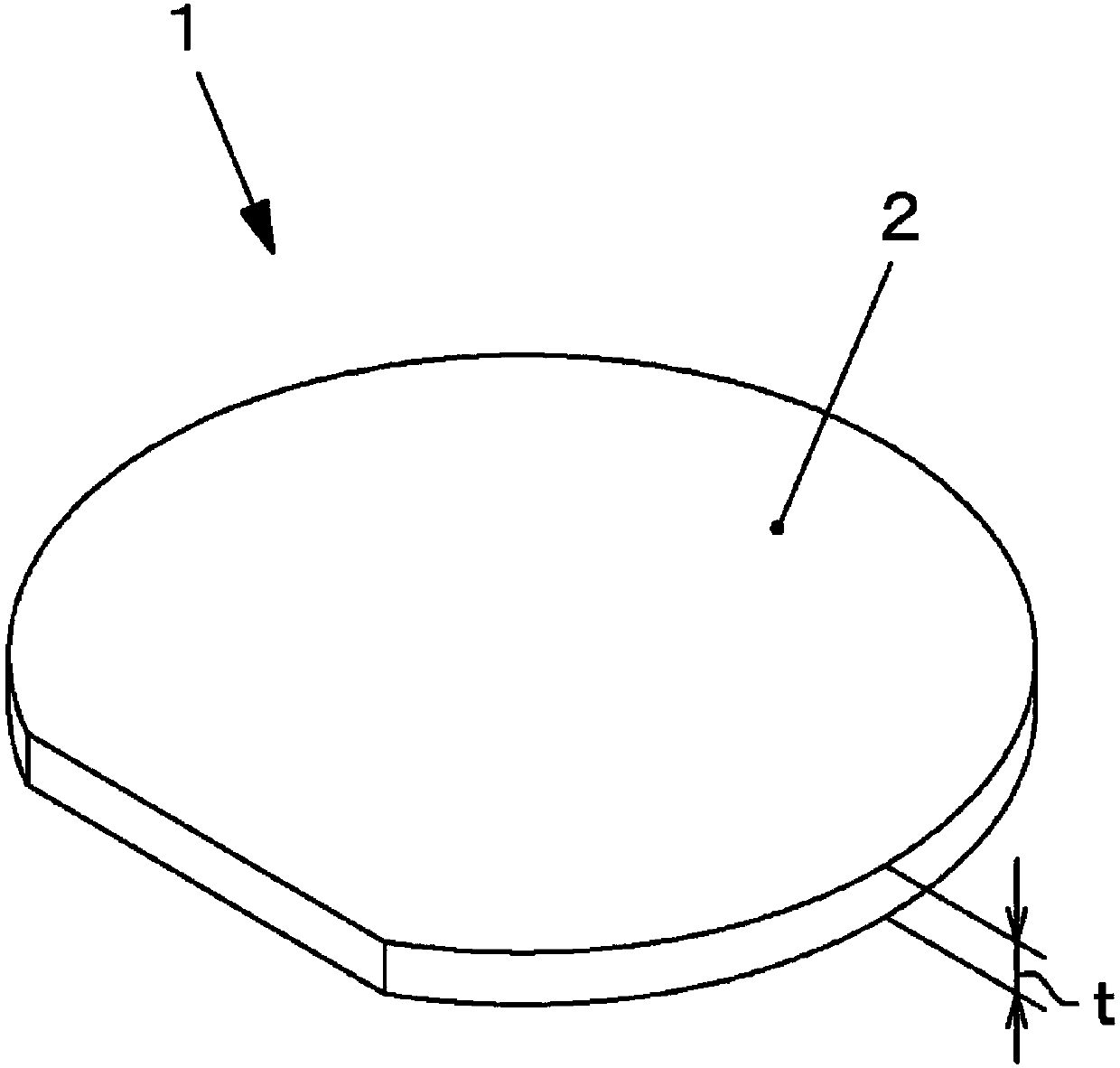

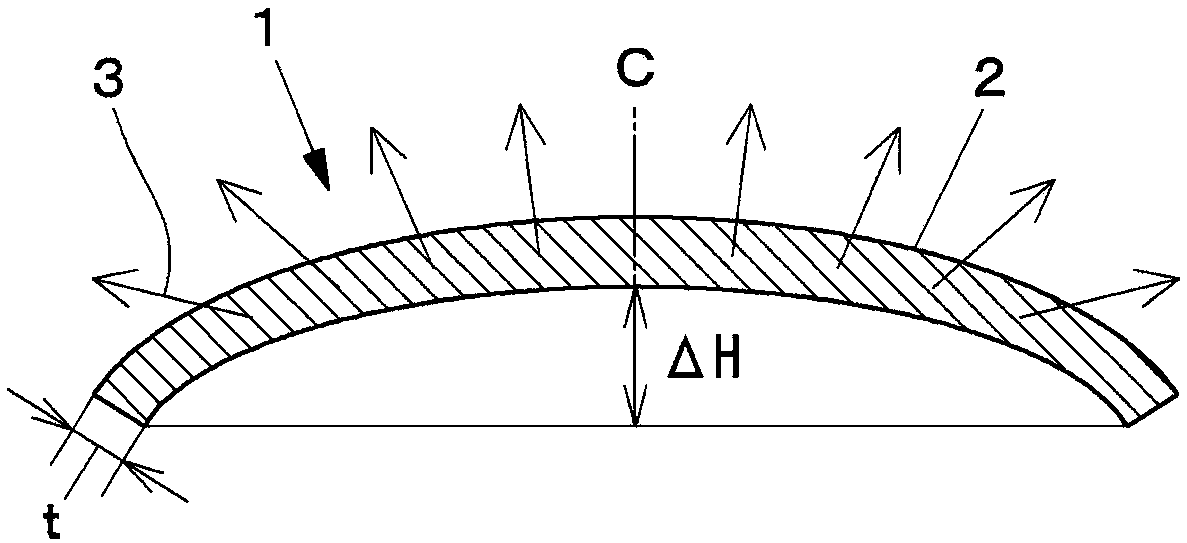

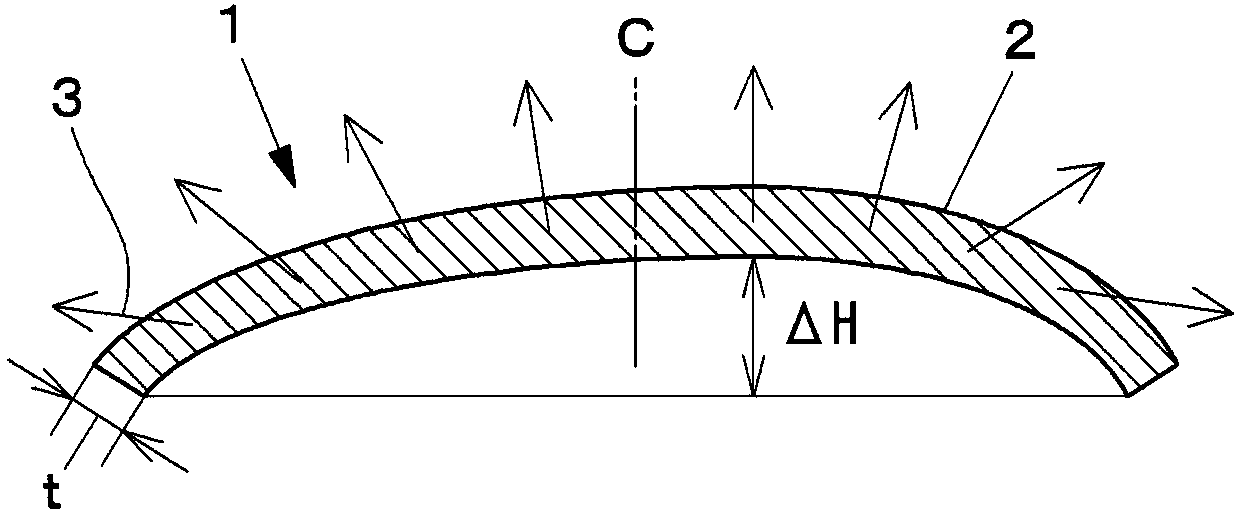

[0057] The first feature of this embodiment is that the diamond substrate is composed of a diamond single crystal, the difference between the highest part and the lowest part in the thickness direction of the diamond substrate exceeds 0 μm and is 485 μm or less, and the deviation of the crystal axis angle over the entire surface of the diamond substrate is More than 0° and less than 3.00°. According to this structure, the crystal axis of the semiconductor film formed on the entire surface of the diamond substrate can be reduced from the influence of the deviation of the crystal axis of the diamond substrate, so the angle deviation of the crystal axis of the semiconductor film is reduced, and the deviation of the semiconductor film can be suppressed. Properties deviate within the plane. At the same time, when heating a functional thin film (such as a semiconductor film, etc.) during film formation, the temperature in the surface of the diamond substrate can be made more uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com