ECO (Epichlorohydrin) ion-conducting type spongy charging roller and preparation method thereof

An ion-conducting and conductive sponge technology, which is applied to equipment, corona discharge devices, and electrical recording technology applying charge patterns, etc., can solve the problems of short service life, poor conductivity, mechanical properties and durability problems such as poor performance, long service life, improved electrical conductivity, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

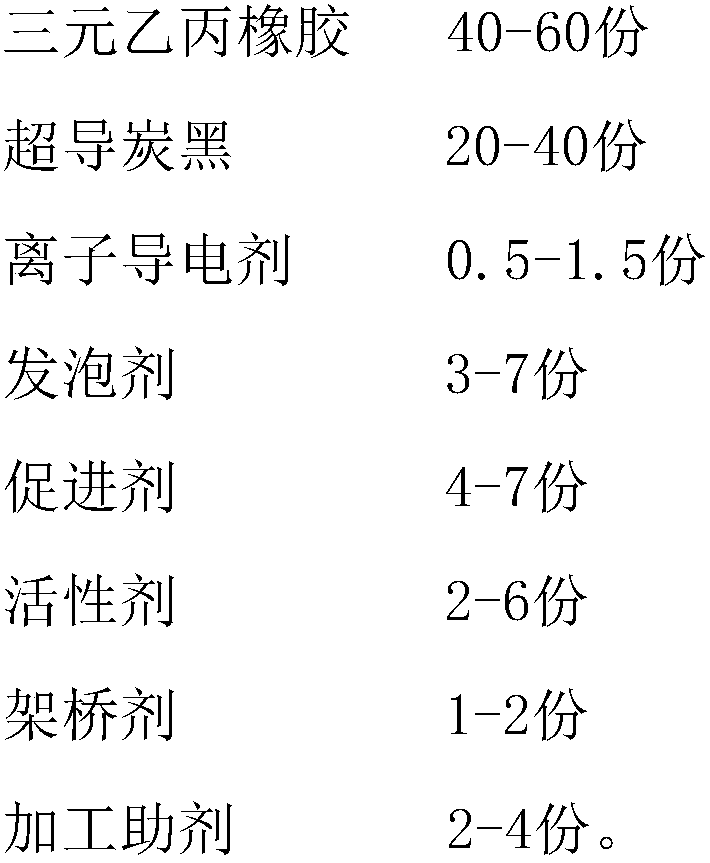

[0043] An ECO ion-conductive sponge charging roller, comprising a roller shaft, a foamed conductive sponge layer sleeved outside the roller shaft, and an ECO ion-conductive rubber layer sleeved outside the foamed conductive sponge layer; the foamed conductive sponge The layer is made of the following raw materials in parts by weight:

[0044]

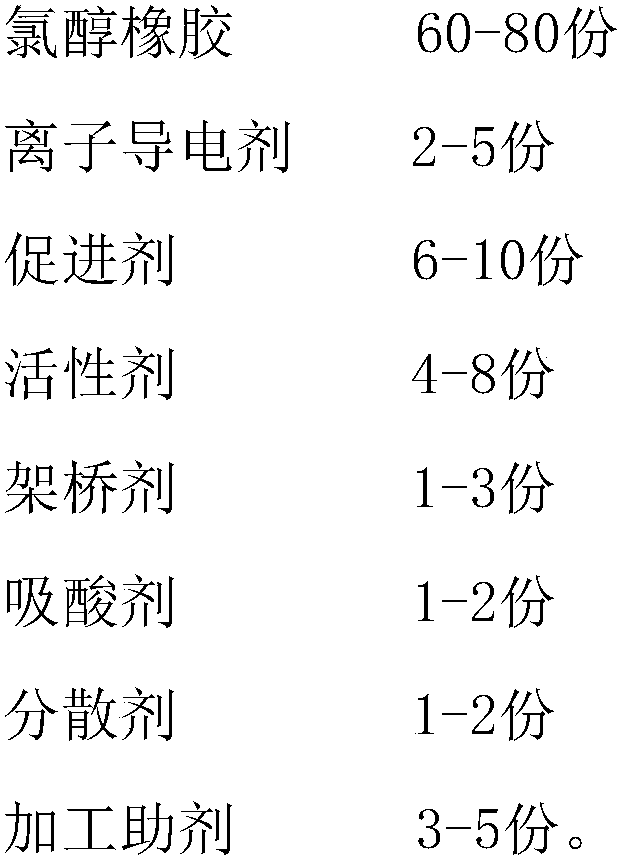

[0045] The ECO ion conductive rubber layer is made of the following raw materials in parts by weight:

[0046]

[0047] The ion-conducting agent is ammonium sulfate, ammonium nitrate or ammonium iodide.

[0048] The blowing agent is a mixture composed of 4,4-oxobisbenzenesulfonyl hydrazide, azodicarbonamide and diisopropyl azodicarboxylate in a weight ratio of 2:1.5:1.

[0049] The accelerator is a mixture of zinc dibutyldithiocarbamate and 2-mercaptobenzothiazole in a weight ratio of 2:1; the active agent is made of zinc oxide, zinc stearate and polyethylene glycol A mixture of diols in a weight ratio of 1.5:0.8:1.

[0050]The...

Embodiment 2

[0059] The difference between this embodiment and the above-mentioned embodiment 1 is that the foamed conductive sponge layer is made of the following raw materials in parts by weight:

[0060]

[0061]

[0062] The ECO ion conductive rubber layer is made of the following raw materials in parts by weight:

[0063]

[0064] The ionic conductive agent is LiBF 4 、LiPF 6 or LiAsF 6 .

[0065] The foaming agent is a mixture composed of 4,4-oxobisbenzenesulfonyl hydrazide, azodicarbonamide and diisopropyl azodicarboxylate in a weight ratio of 2.5:1.8:1.

[0066] The accelerator is a mixture of zinc dibutyldithiocarbamate and 2-mercaptobenzothiazole in a weight ratio of 2.5:1; the active agent is made of zinc oxide, zinc stearate and polyethylene A mixture of diols in a weight ratio of 1.8:0.9:1.

[0067] The bridging agent is a vinyl chloride-vinyl acetate-butyl acrylate terpolymer with a vinyl chloride unit content of 45%, a vinyl acetate unit content of 27.5%, and a ...

Embodiment 3

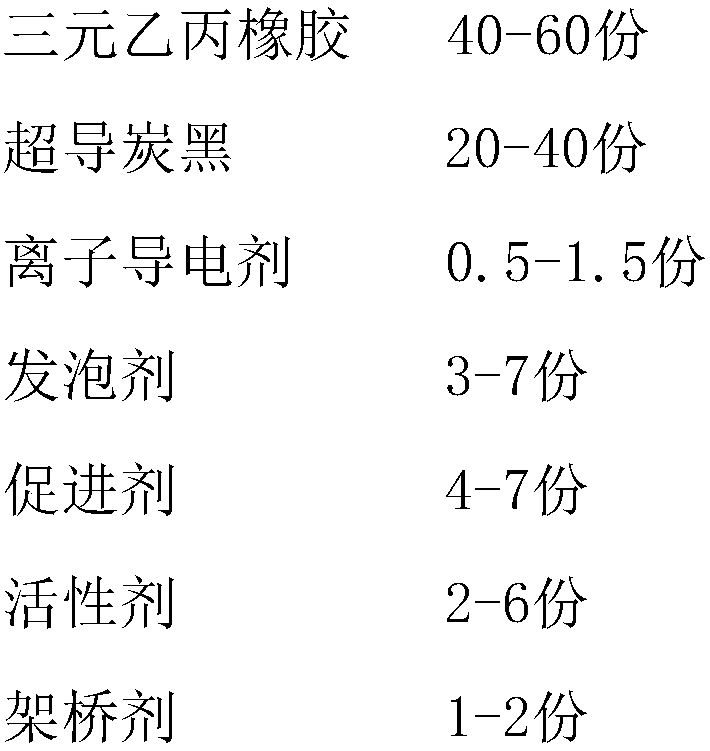

[0070] The difference between this embodiment and the above-mentioned embodiment 1 is that the foamed conductive sponge layer is made of the following raw materials in parts by weight:

[0071]

[0072] The ECO ion conductive rubber layer is made of the following raw materials in parts by weight:

[0073]

[0074] The ion-conducting agent is LiSbF 6 or LiCF 3 SO 3 .

[0075] The foaming agent is a mixture composed of 4,4-oxobisbenzenesulfonyl hydrazide, azodicarbonamide and diisopropyl azodicarboxylate in a weight ratio of 3:2:1.

[0076] The accelerator is a mixture of zinc dibutyldithiocarbamate and 2-mercaptobenzothiazole in a weight ratio of 3:1; the active agent is made of zinc oxide, zinc stearate and polyethylene A mixture of diols in a weight ratio of 2:1:1.

[0077] The bridging agent is a vinyl chloride-vinyl acetate-butyl acrylate terpolymer with a vinyl chloride unit content of 50%, a vinyl acetate unit content of 25%, and a butyl acrylate unit content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com