Bobbin winder of doubling machine

A technology of winding device and spool, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve problems such as limiting the use range of braided cladding, and achieve far-reaching application prospects and economic prospects, convenient maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

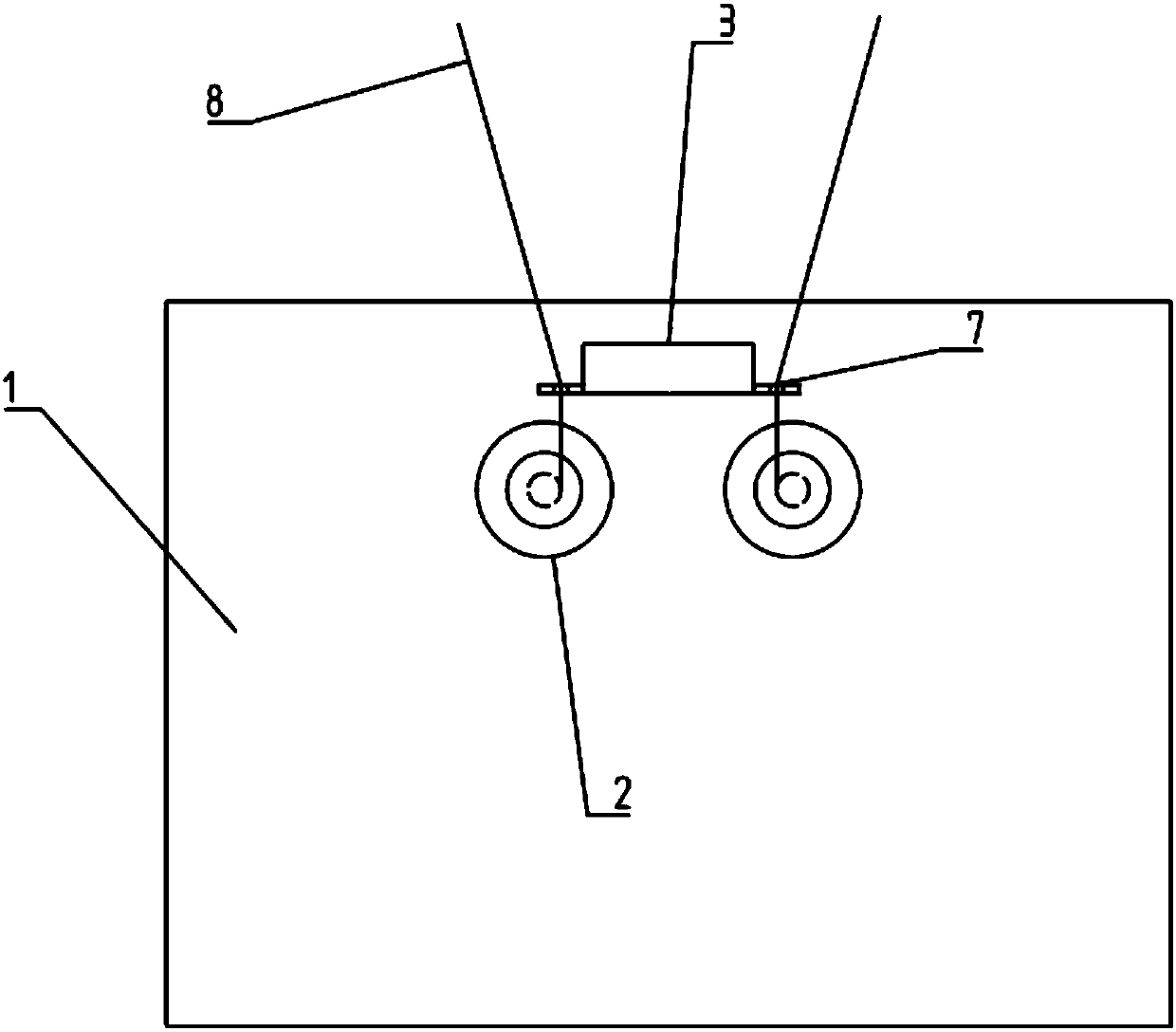

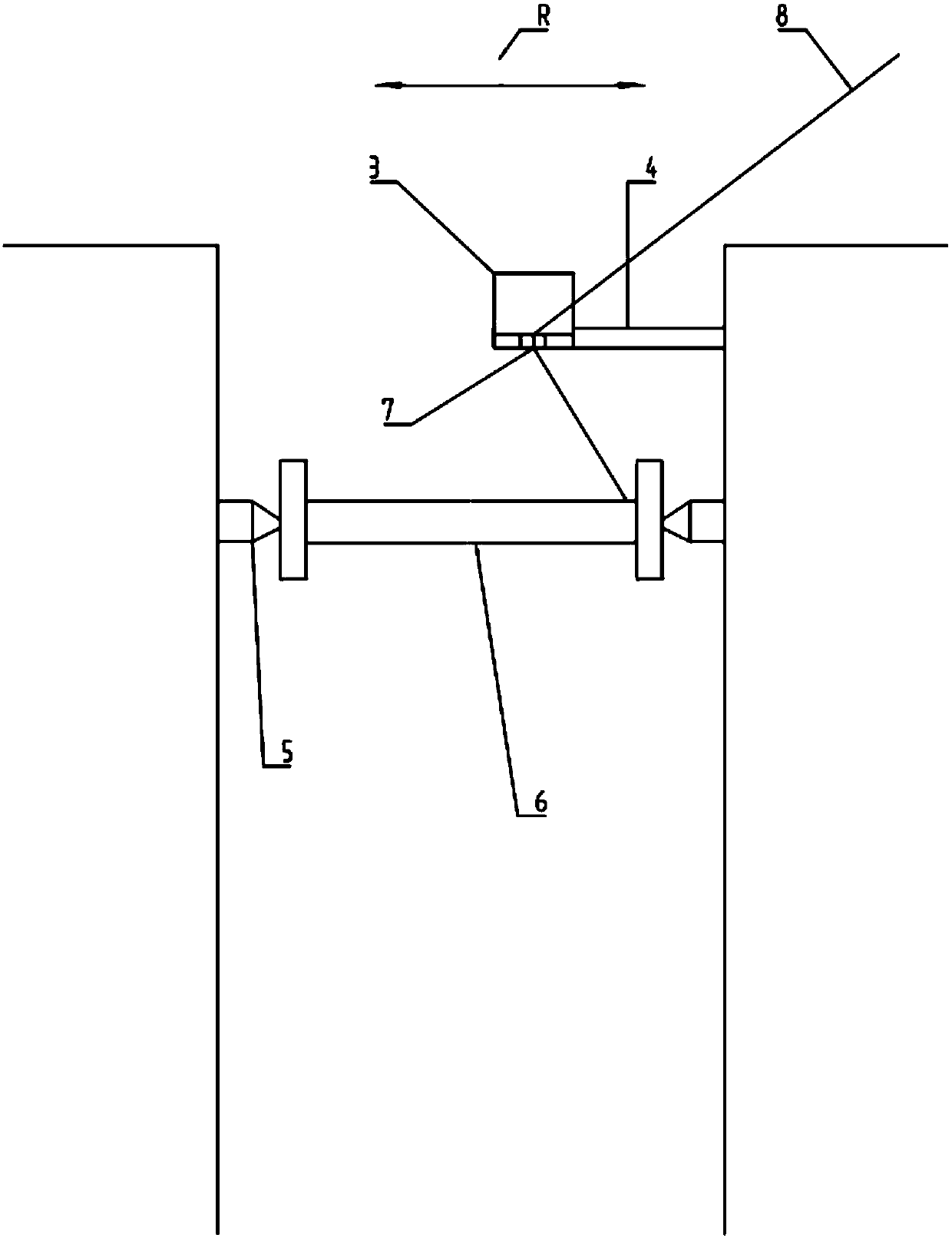

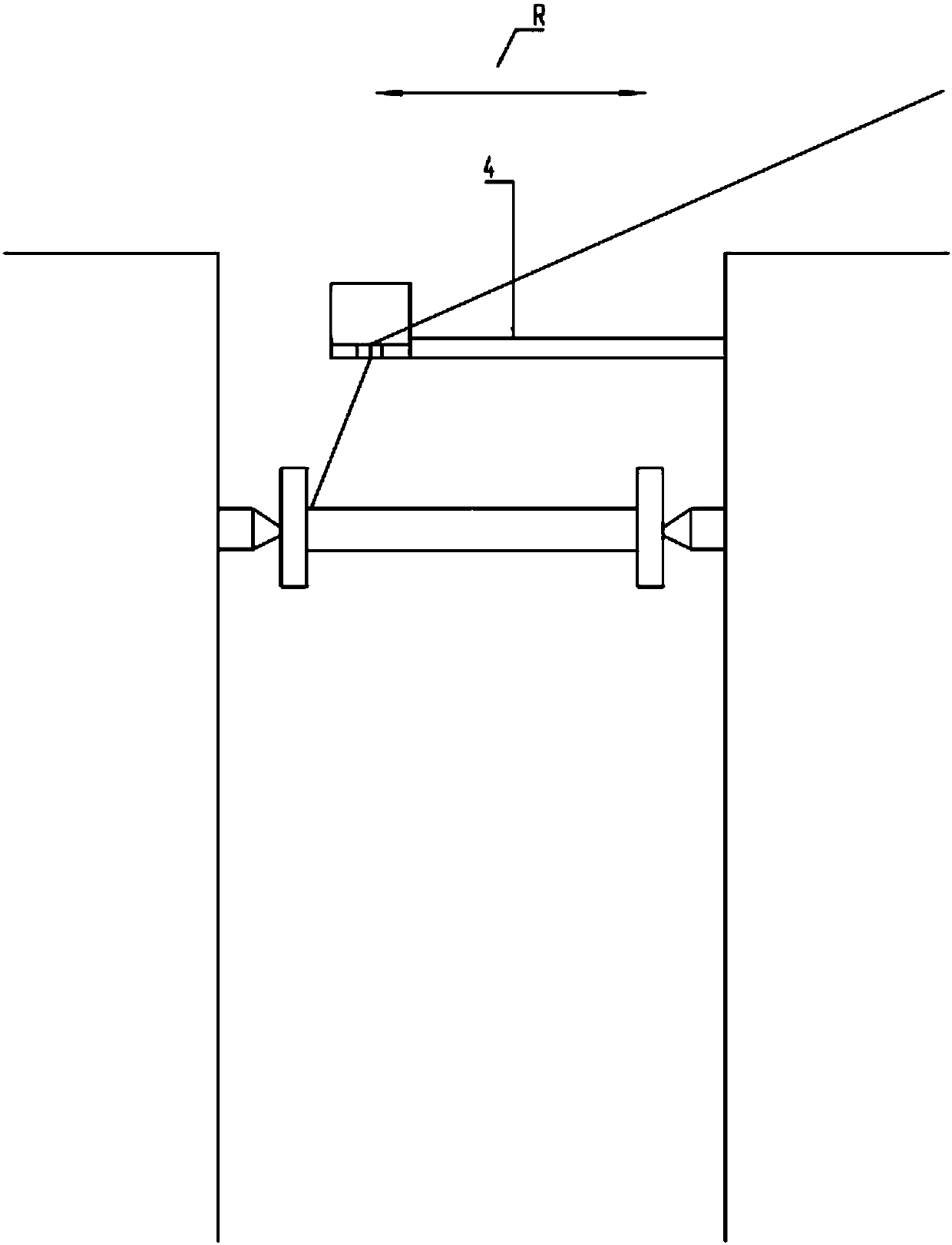

[0015] Such as Figure 1-3 Shown is an embodiment of the winding device of the doubling machine according to the present invention.

[0016] The winding device of the doubling machine includes a machine 1, a rotor 2, a wire guide 3, a slide bar 4, a clamping part 5, a bobbin 6, and a wire hole 7, wherein the machine 1 is composed of two parts and separated from each other by a certain distance, A space for accommodating the bobbin 6 is formed between them, a pair of symmetrical rotors 2 are arranged on the front of a part of them, a wire guide 3 is arranged above the two rotors 2, and wire holes 7 are respectively arranged on both sides of the wire guide 3 , the yarn 8 is wound onto the bobbin 6 located on the rotor 2 through the wire hole 7, wherein the rotor 2 is provided with a clamping part 5 for clamping both ends of the bobbin 6, the thread guide 3 is connected with a slide bar 4, and the slide One end of the rod 4 is connected to the thread guide 3, and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com