Robot hardware abrasive belt grinding unit device based on program reuse

An abrasive belt grinding and unit device technology, applied in automatic grinding control devices, abrasive belt grinders, program control manipulators, etc., can solve the problems of inconsistent grinding quality and poor inheritance of grinding procedures, and achieve high quality, high-quality batch grinding. The effect of high grinding stability and easy production change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in more detail and complete below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

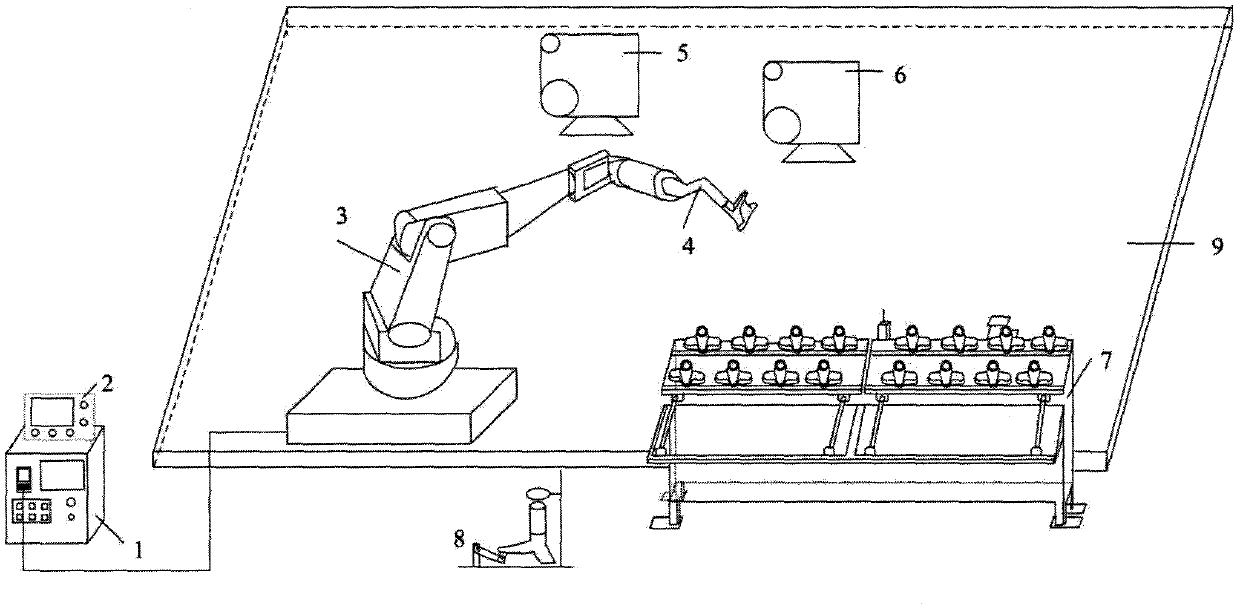

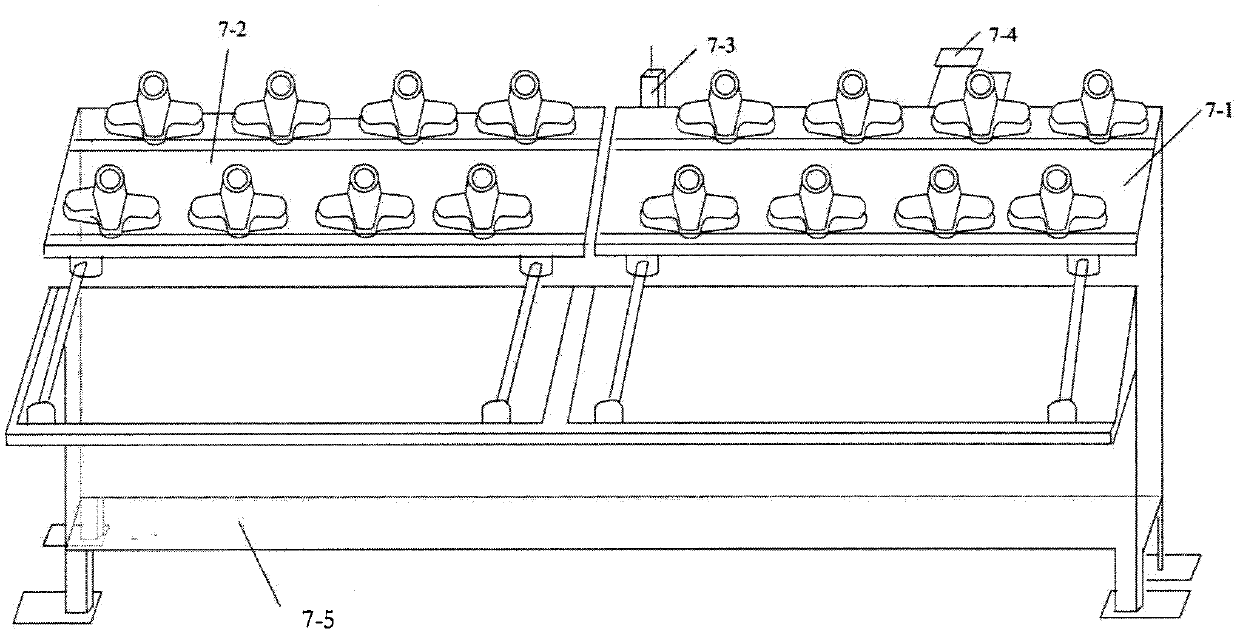

[0037] see figure 1 , a mechanical hardware system of a robot hardware abrasive belt grinding unit device based on program reuse technology of the present invention includes a robot electric cabinet 1, an operation panel 2, a six-degree-of-freedom robot 3, a self-expanding fixture 4, a coarse sand Belt grinding machine 5, fine sand belt machine 6, automatic loading and unloading slide table 7, tooling measuring tool 8, equipment installation base 9;

[0038] The robot electric cabinet 1 is connected to the operation panel 2. When the control panel 2 sends relevant operation instructions, the robot electric cabinet 1 receives the corresponding instructions, converts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com