A grinding device for the production of hardware accessories

A technology for accessories and hardware, applied in the field of grinding devices, can solve the problems of manual grinding, time-consuming and labor-intensive, and low grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

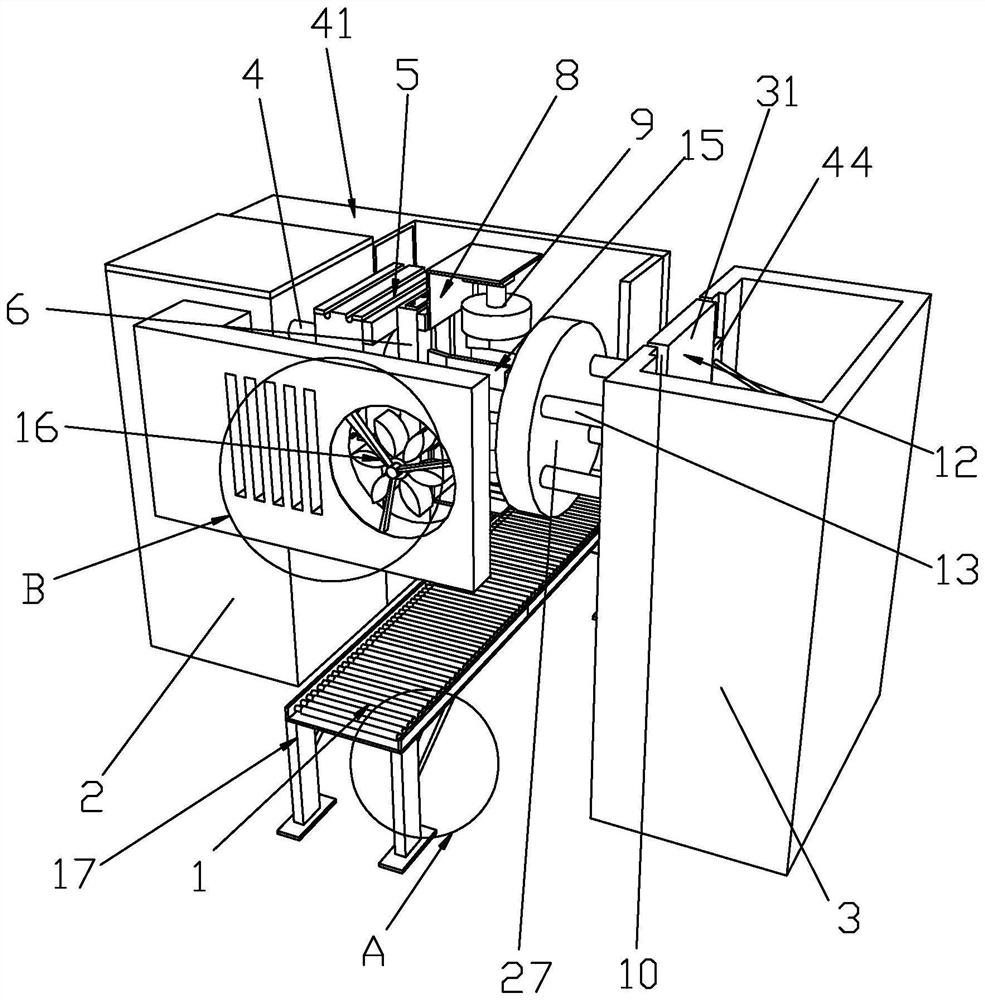

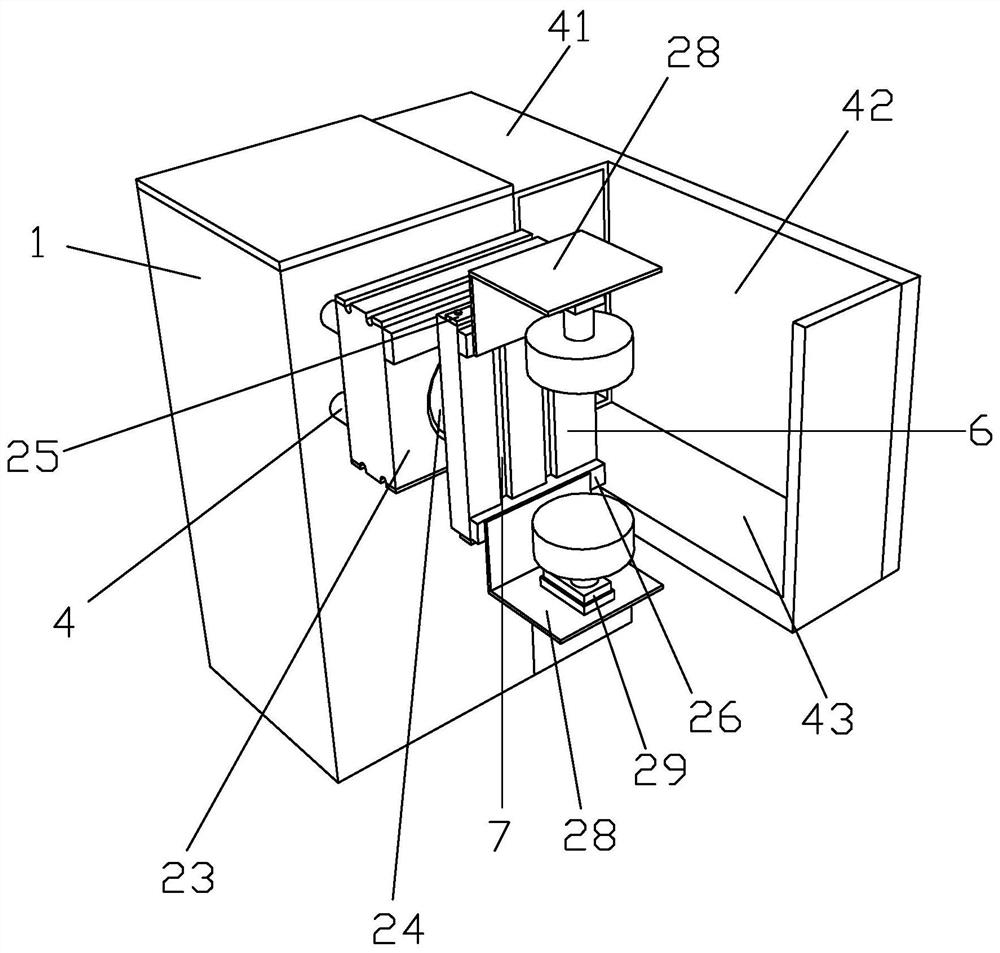

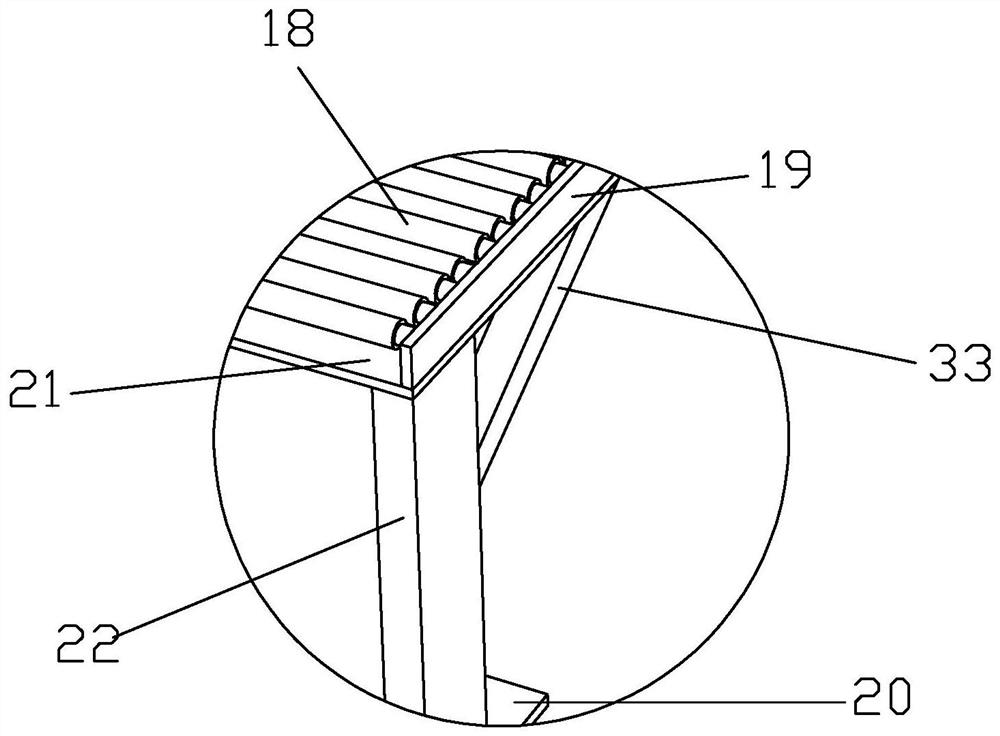

[0030] The specific embodiment of the present invention: open the transmission device 1 to transport the hardware accessories to be polished at a constant speed, start the lifting device in the second motor box 3, drive the sliding mechanism to slide downward, and when it slides to the top of the hardware accessories, the clamping block slides down Make the hardware accessories between the clamping blocks, the hardware device is blocked by the left clamping block, stop running, the third sliding block slides, the clamping block fixes the hardware accessories, the lifting device is lifted upwards to the set position, and stretches The rod 4 is elongated and the transmission device is driven at the same time, so that the grinder 9 is vertically opposite to each other. When the position of the grinder 9 is directly above the hardware accessories, the telescopic rod 4 stops running, the grinder 9 is opened, and the sliding plate 8 slides to the hardware fittings. The accessories ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com