Cylindrical workpiece multi-union clamp

A technology for cylindrical, workpieces, used in the field of multiple fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

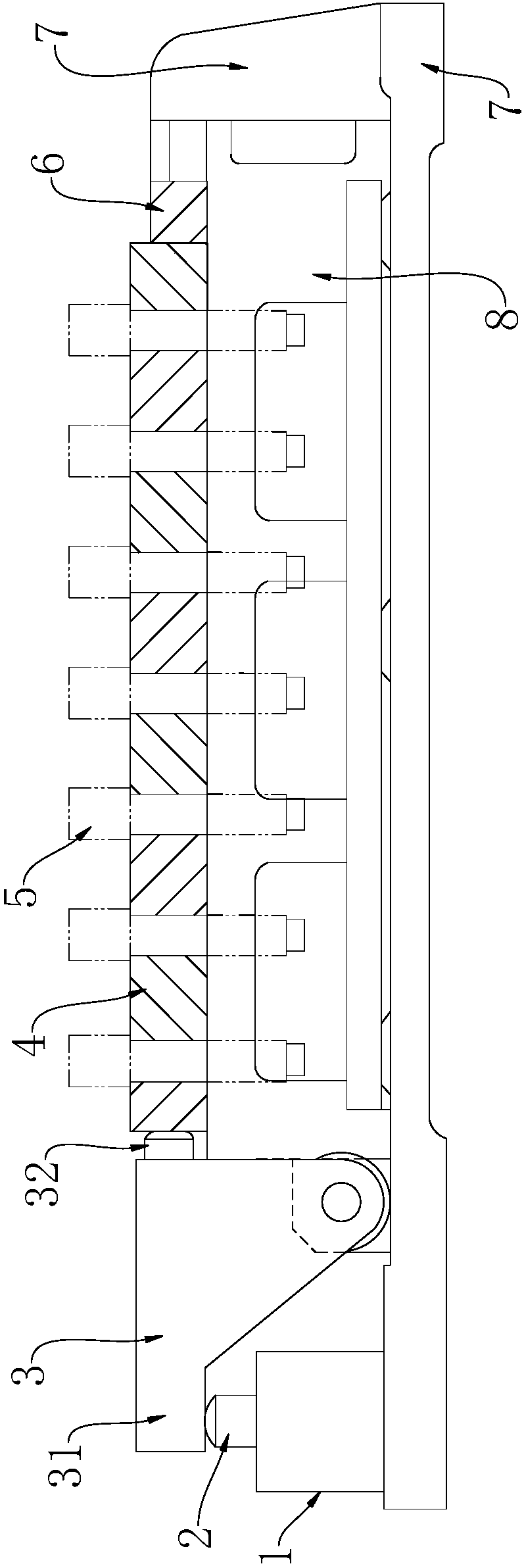

[0017] Such as Figures 1 to 3 As shown, the multi-joint fixture for cylindrical workpieces includes a base 7, and a cylinder 1 and a fixed frame 8 are fixedly installed on the base 7 from left to right in turn, and a lower end and a base 7 are arranged between the cylinder 1 and the fixed frame 8 The hinged direction-changing transmission block 3, the left end of the transmission block 3 is the force arm 31, the right end of the transmission block 3 is the top 32, the lower end surface of the force arm 31 abuts against the top of the cylinder 1 piston rod 2, and the fixed frame 8 is movably connected with a clip Block module 4, the right end of the clamping block module 4 abuts against the fixed frame 8, and the left end of the clamping block module 4 is aligned with the top 32 at the right end of the transmission block 3.

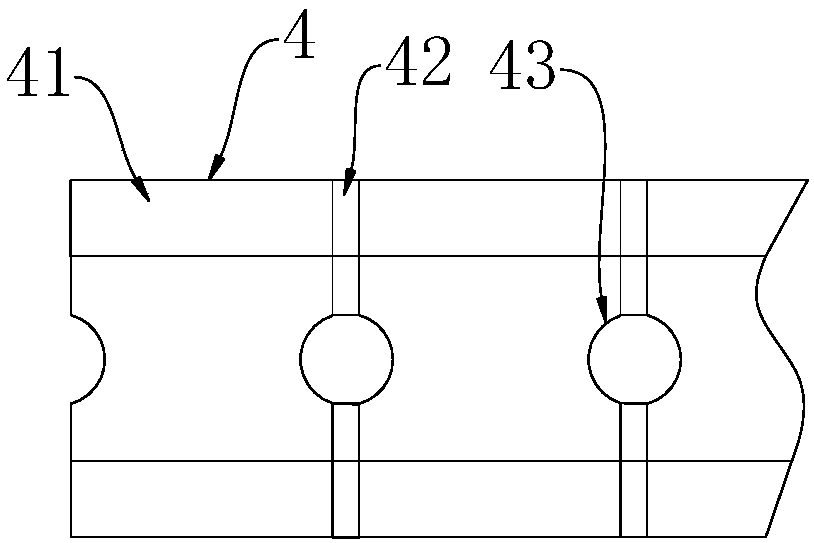

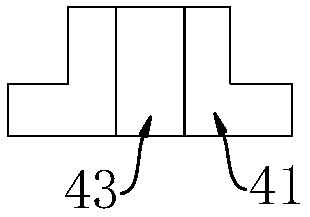

[0018] Clamp block module 4 comprises several clamp blocks 41 of identical structure, and all clamp blocks are arranged in a row, and the flexible block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com