Lead-free soldering paste for fine distance of 0.25 mm and preparing method of lead-free soldering paste

A lead-free solder paste, fine-pitch technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as serious bridging and short-circuiting of components, and achieve excellent thermal slump resistance, good solderability, and contact. Excellent denaturation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

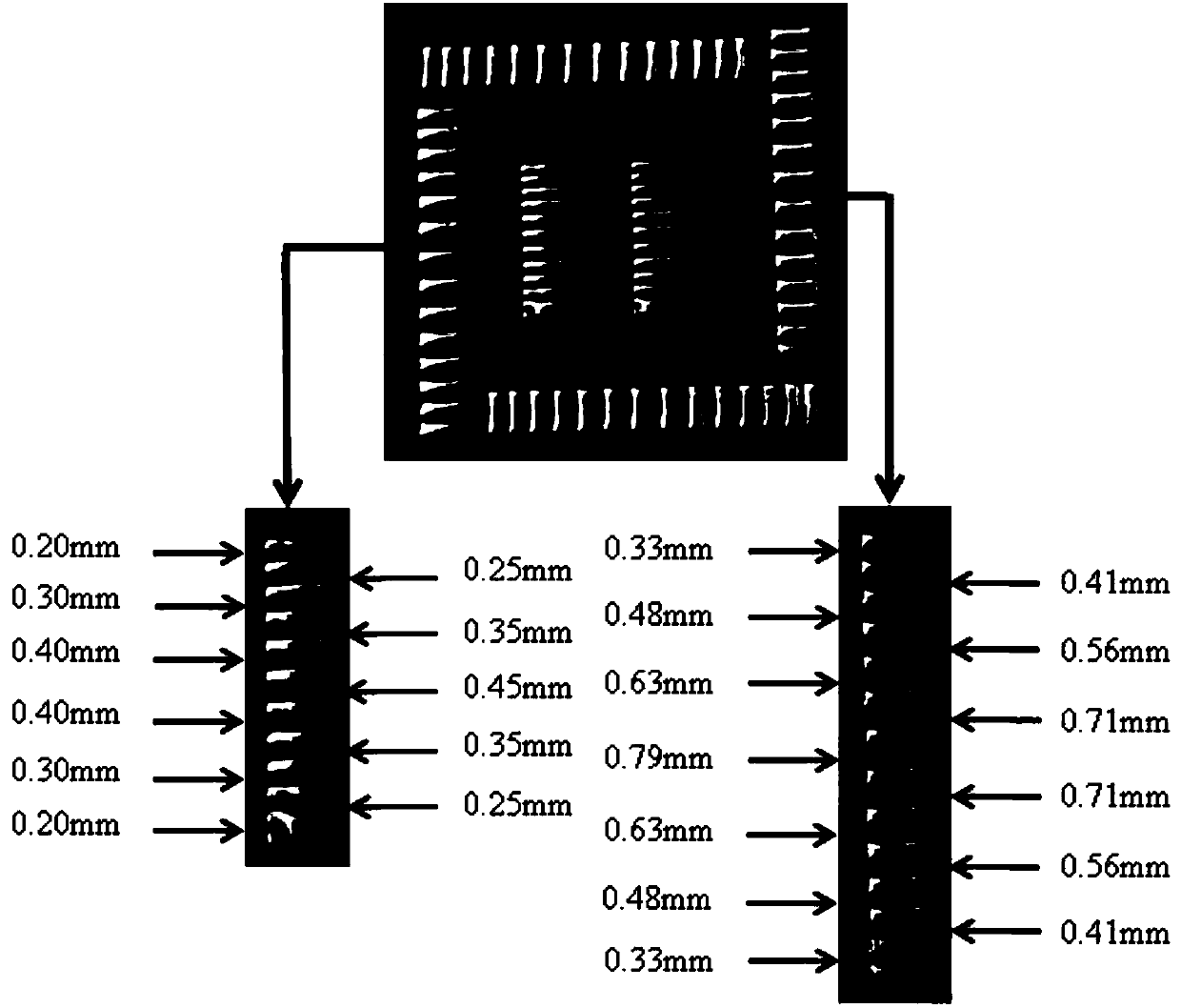

Image

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned 0.25mm fine-pitch lead-free solder paste, the specific steps are as follows:

[0027] Step 1: Weigh 35%-50% of rosin, 6%-12% of active agent, 6%-9% of thixotropic agent according to mass percentage, and the balance is solvent. The sum of the mass percentages of the above components is 100%, wherein , the rosin taken is a mixture of acrylic acid modified rosin and hydrogenated rosin;

[0028] Step 2: Add the solvent weighed in step 1 into the reaction vessel, heat to 125°C-135°C, add acrylic acid-modified rosin, and stir at constant temperature until the solution is uniform and transparent;

[0029] Step 3: Cool down the solution obtained in step 2 to 100°C-110°C, add the active agent weighed in step 1, and stir at constant temperature until the solution is uniform and transparent;

[0030] Step 4: Cool down the solution obtained in step 3 to 80°C-90°C, add the hydrogenated rosin weighed in step 1, and stir at a constant tem...

Embodiment 1

[0036] Heat 47% diethylene glycol monohexyl ether to 125°C-135°C, add 20% acrylic acid-modified rosin, and stir at constant temperature until it becomes transparent. Cool down to 100°C-110°C, add 8% azelaic acid and 4% sebacic acid, and stir at constant temperature until the solution is uniform and transparent. Cool down to 80°C-90°C, add 15% hydrogenated rosin, and stir until transparent. Cool down to 70°C-80°C, add 2% polyamide wax and 4% Thixatrol ST, and stir at constant temperature until the solution is uniform and transparent. Turn off the heat and continue stirring until the solution is a creamy flux. Mix 10% flux and 90% solder powder and stir evenly to get lead-free solder paste.

Embodiment 2

[0038] Heat 47% 1,2-propanediol to 125°C-135°C, add 20% acrylic acid modified rosin, and stir at constant temperature until transparent. Cool down to 100°C-110°C, add 6% sebacic acid and 6% salicylic acid, and stir at constant temperature until the solution is uniform and transparent. Cool down to 80°C-90°C, add 15% hydrogenated rosin, and stir until transparent. Cool down to 70°C-80°C, add 3% polyamide wax and 3% thixotropic agent 6500, and stir at constant temperature until the solution is uniform and transparent. Turn off the heat and continue stirring until the solution is a creamy flux. Mix 10.5% flux with 89.5% solder powder and stir evenly to obtain lead-free solder paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com