Disintegration tank with shock resistance

A shock-resistant and high-capacity technology, applied in the field of decay pools, can solve problems such as poor anti-accident shock capability, high cost, and complex control and operation management in the later stage, so as to achieve the effect of anti-accident shock capability and improve safety redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

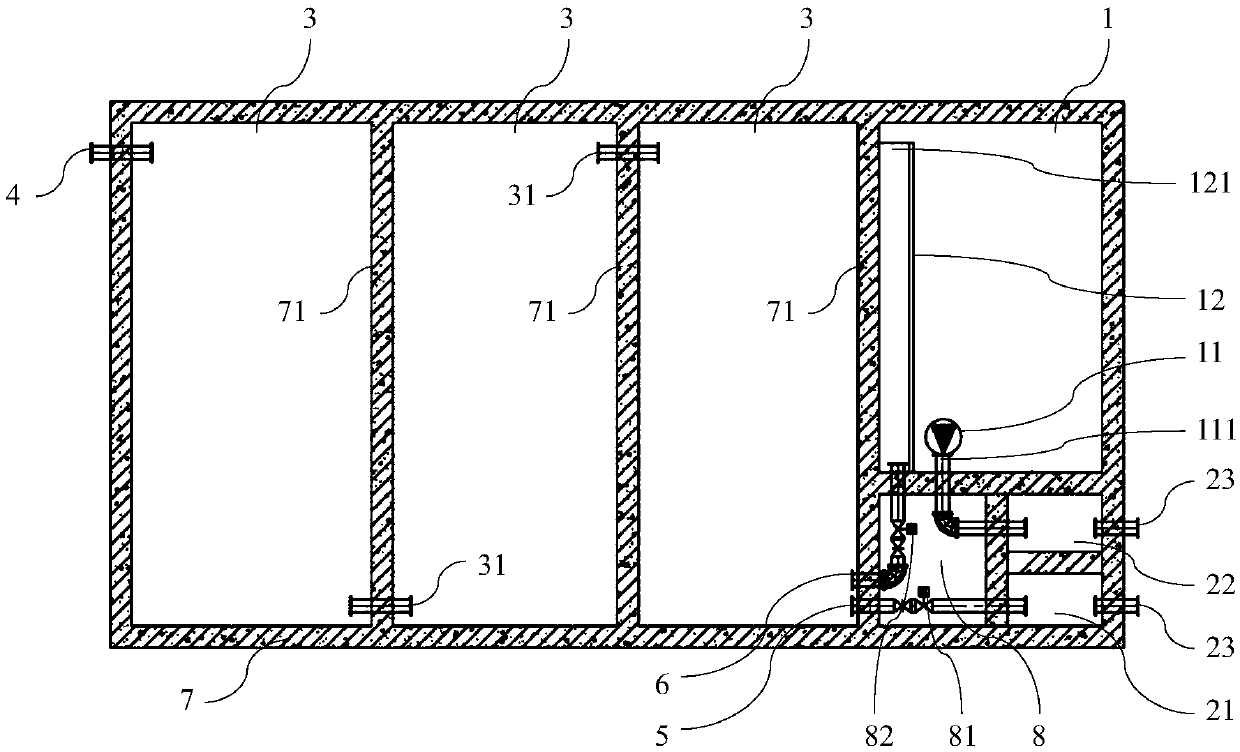

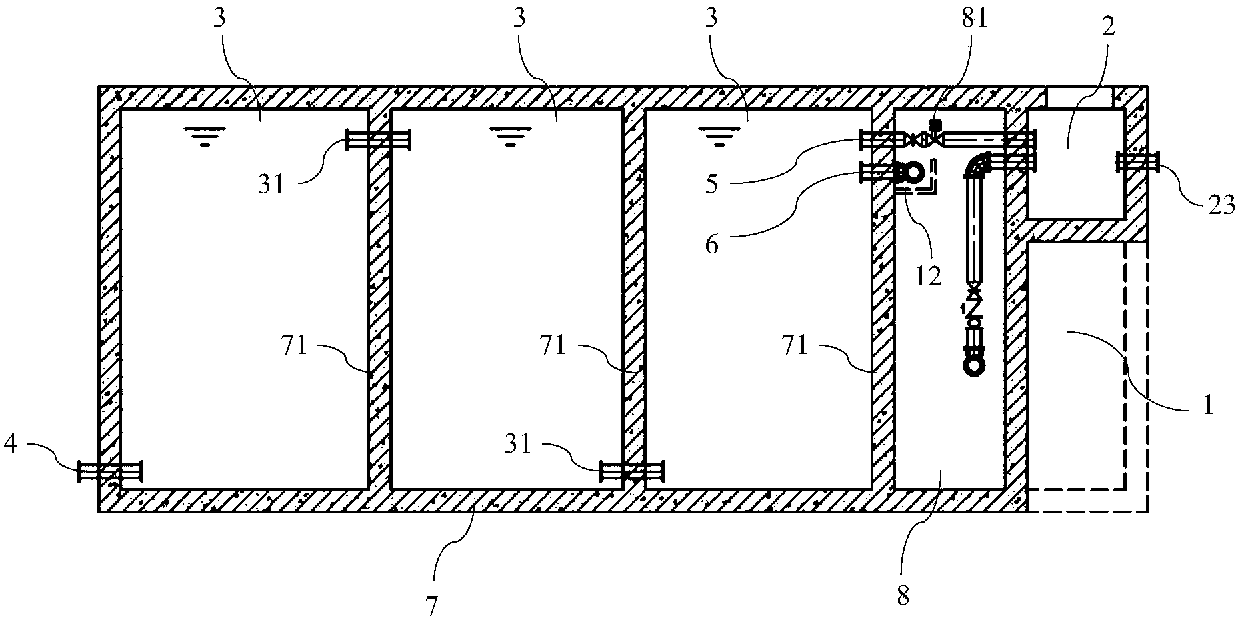

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0019] to combine figure 1 with figure 2 As shown, the decay cell with impact resistance of the present invention is schematically shown, including an adjustment cell 1, a detection cell 2 and a plurality of decay cells 3 connected in sequence through conduits 31, and the detection cell 2 includes a first detection cell 21 and The second detection pool 22, the decay pool 3 located at the head end is connected to be provided with the water inlet pipe 4, and the decay pool 3 located at the tail end is communicated with the first detection pool 21 and the regulating pool 1 through the water outlet pipe 5 and the bypass pipe 6 respectively, and the water outlet pipe 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com