Chemical etching measurement method for optical element sub surface damages, auxiliary experiment device and test method

A technology of subsurface damage and chemical etching, which is applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of difficulty in ensuring accuracy, impracticality, high equipment requirements, etc., to overcome the danger of manual operation, measure The effect of low equipment requirements and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

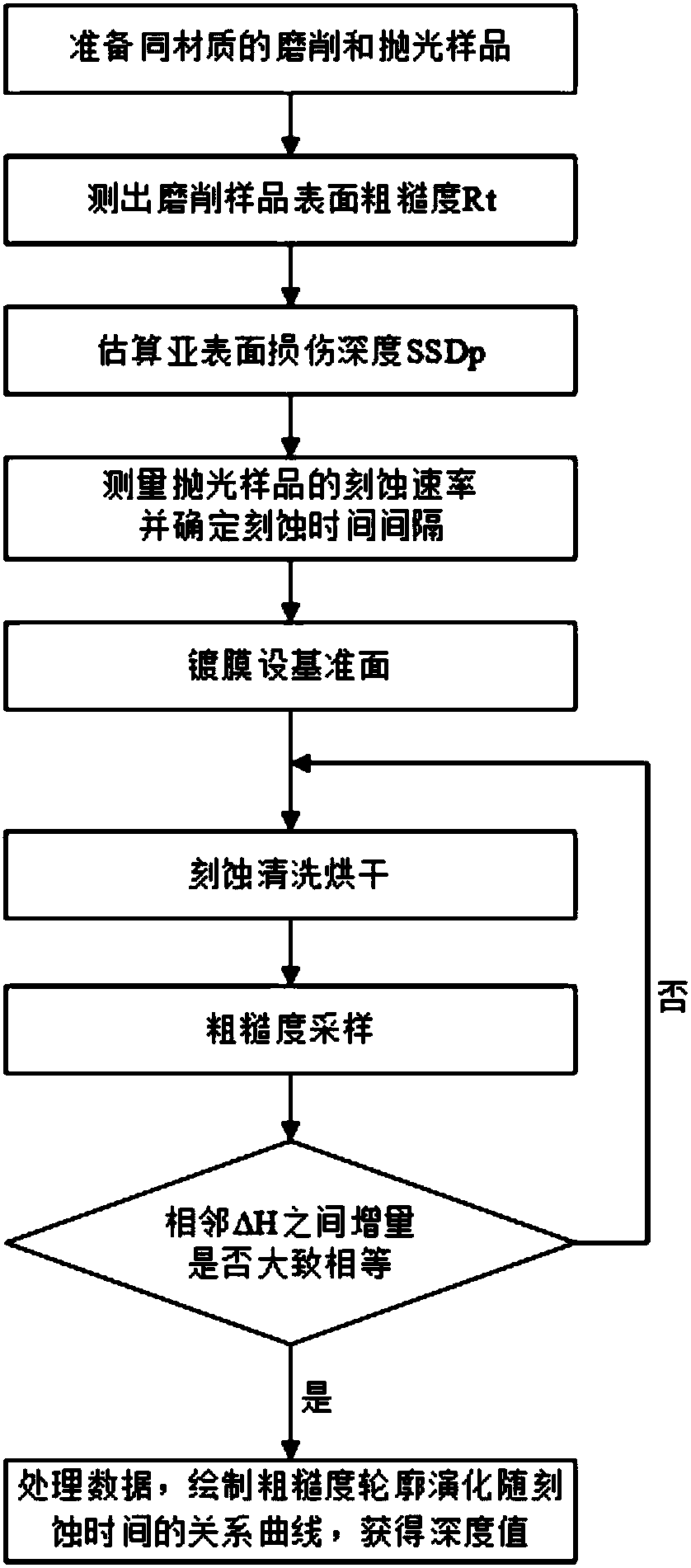

[0074] Examples of subsurface damage depth measurements (see figure 1 ):

[0075] (1) Prepare ground and polished samples of the same material. The sample is cylindrical ground and polished K9 glass with a diameter of 30 mm and a thickness of 3 mm, and self-prepared etching solutions: HF and HNO 3 A mixed solution with HF concentration of 40%, HNO 3 The concentration is 65%, the volume ratio is HF:HNO 3 =4:1;

[0076] (2) Use a step meter to randomly measure the roughness of 8 points of the sample grinding sample, and obtain the average value R t =9.6um;

[0077] (3) The theoretical model of the relationship between the grinding subsurface damage depth and surface roughness estimates the subsurface damage depth SSD p :

[0078]

[0079] a k =0.027+0.090(m-1 / 3)=0.027, m=1 / 3

[0080]

[0081] ψ=46°, E=72GPa, H=6GPa, K c =0.75

[0082] SSD p =48.109um;

[0083](4) To measure the etching rate v of the sample, take 9 pieces of polished glass of the same shape as t...

Embodiment 2

[0090] Examples of chemical etching auxiliary devices:

[0091] The process of using the chemical etching auxiliary device is: HF acid etching for 3 minutes, acetone solution cleaning for 3 minutes, alcohol solution cleaning for 3 minutes, ultra-clean water cleaning for 3 minutes, and drying. The ultrasonic oscillator is turned on during the cleaning process, and the blower and motor are turned on during the drying process, so that the blower is aimed at the rotating sample to blow air.

[0092] like image 3 and Figure 4 As shown, the chemical etching auxiliary device mentioned in the above method includes: ultrasonic oscillator 1, support 2, first support rod 3, first fixing bolt 4, first bearing 5, end cover 6, second support Rod 7, blower 8, universally adjustable jet pipe 9, second fixing bolt 10, beam 11, winding wire 12, reel 13, limit rod 14, motor 15, vertical rod 16, second bearing 17, connecting shaft 18. Sample holder 19, sample 20, beaker 21, beaker cover 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com