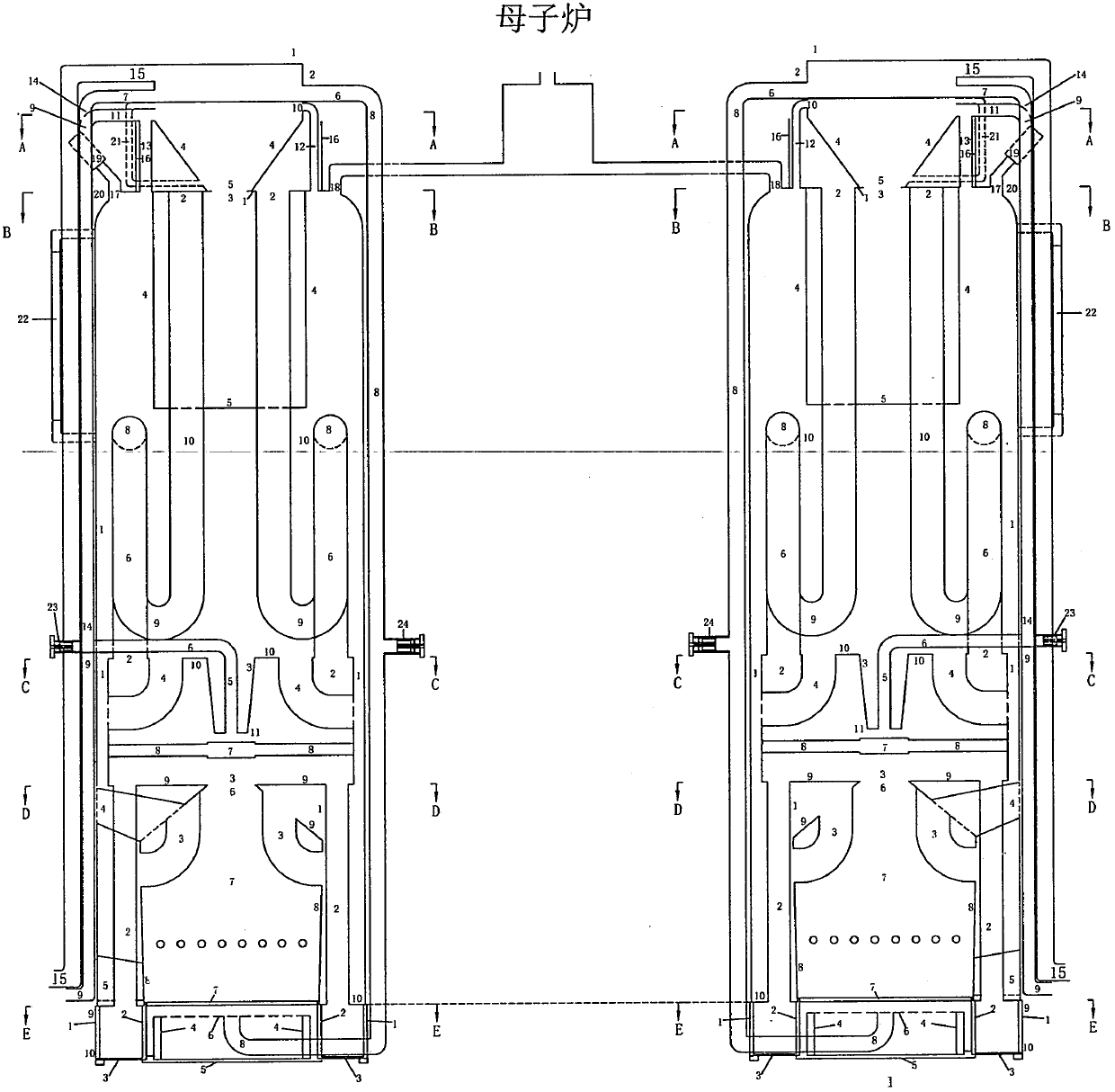

Environment-friendly energy-saving efficient waste incineration power generation gasified parent-subsidiary boiler

A boiler and high-efficiency technology, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of high operating costs, high manufacturing costs, and unsatisfactory garbage disposal, and achieve the effect of low operating costs and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

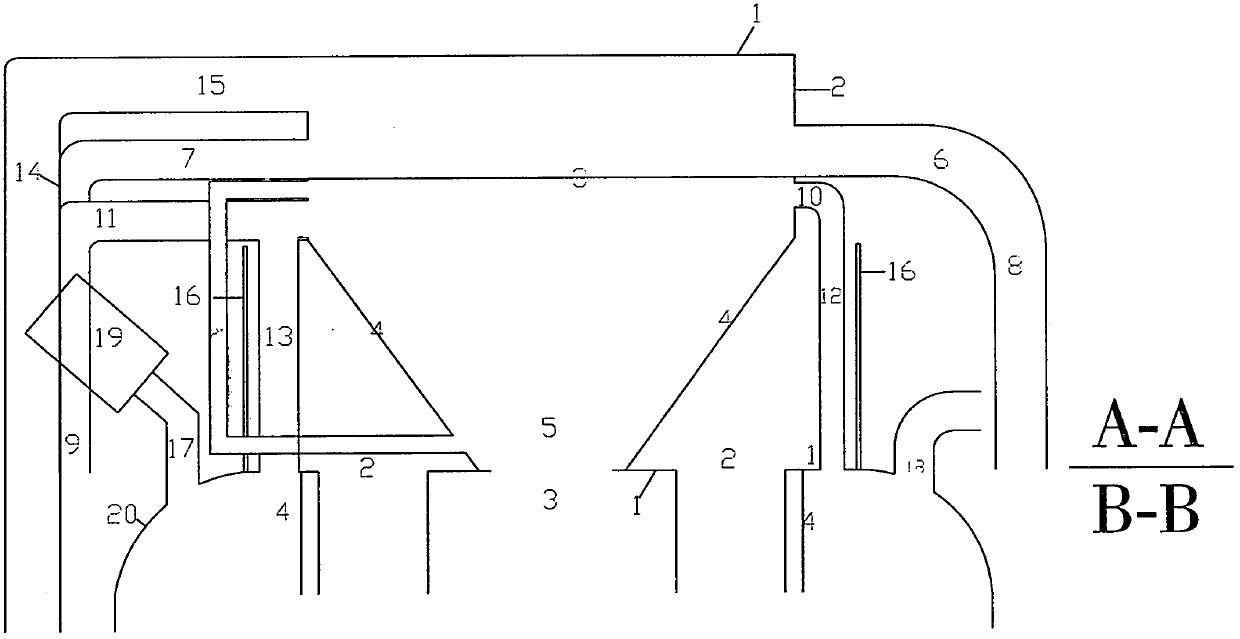

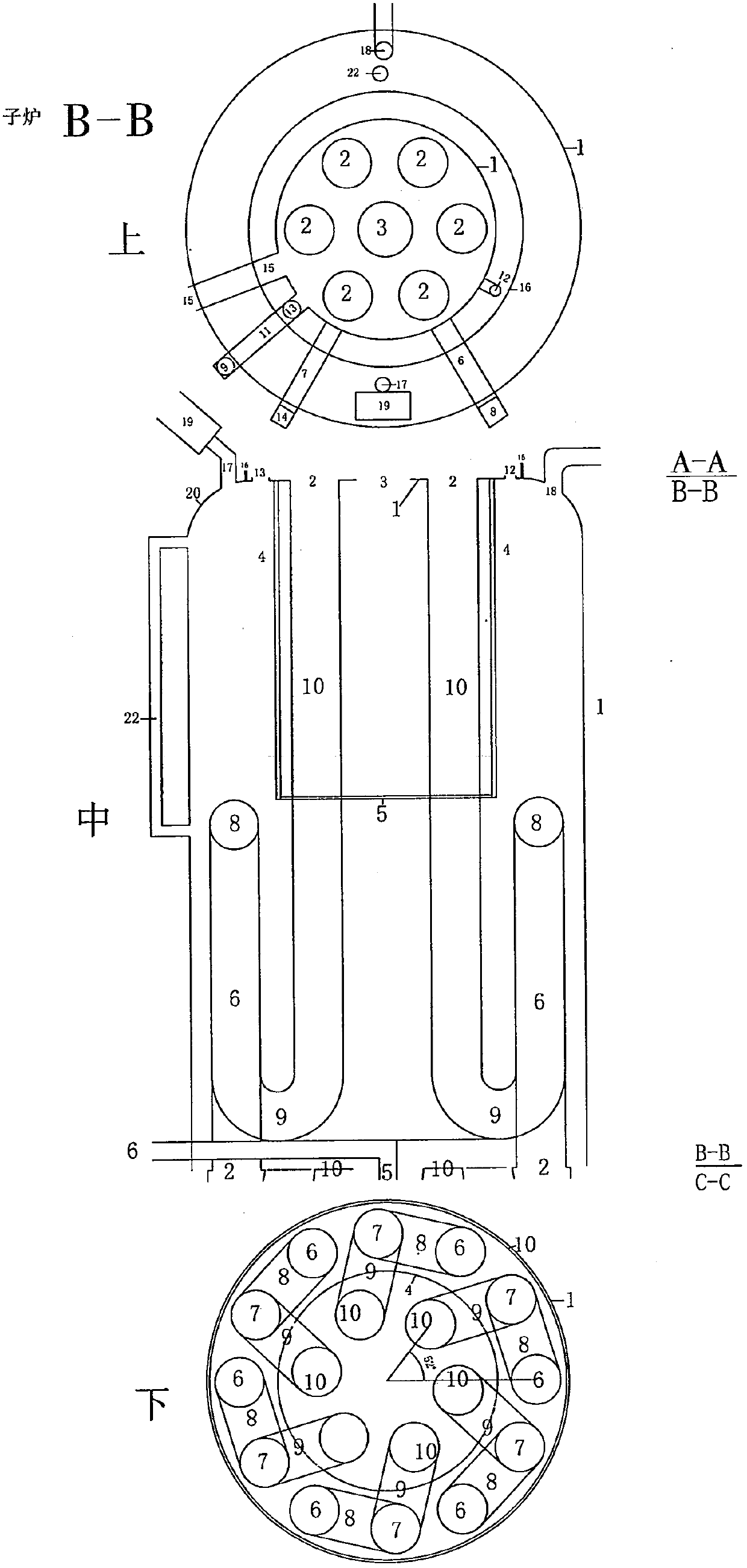

[0095] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS 1. The present invention has the remarkable feature of changing the traditional erroneous combustion method of the boiler. This furnace adopts the principle of gasification. Gasification in the first furnace turns the garbage into coke, and the "smoke" produced by gasification is actually combustible gas, which is then burned in the second furnace, saving more than 30% of energy.

specific Embodiment approach 2

[0096] Specific implementation mode 2. The boiler adopts a wind box installed on the top of the boiler with a miniature electric fan, and the wind is transported into the wind box by the pipeline.

specific Embodiment approach 3

[0097] The specific embodiment three, in the second combustion chamber of C part, an oxygen replenishing device is designed, and the hot air pipe (7) (14) is delivered to the second combustion chamber of C part (6) by the A part air box. To achieve oxygen supplement combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com