A boom lubrication process

A crane arm and process technology, which is applied in the field of lubrication technology, can solve problems such as poor work quality, backward technology, and no lubrication effect, and achieve the effects of improved work efficiency, uniform spray thickness, and ideal spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

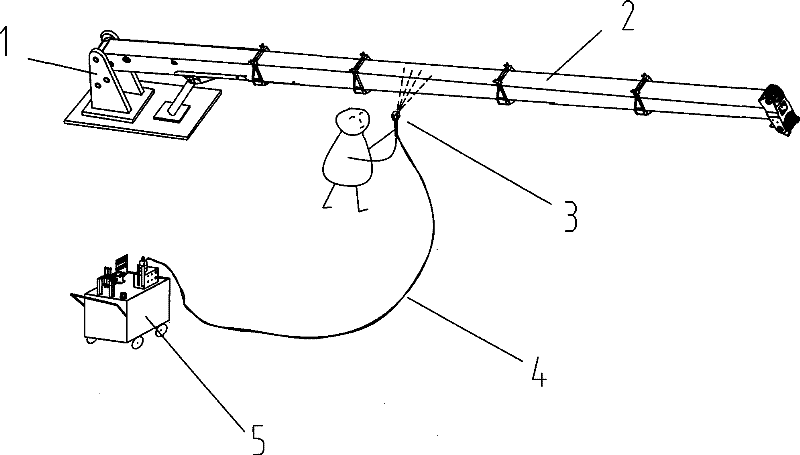

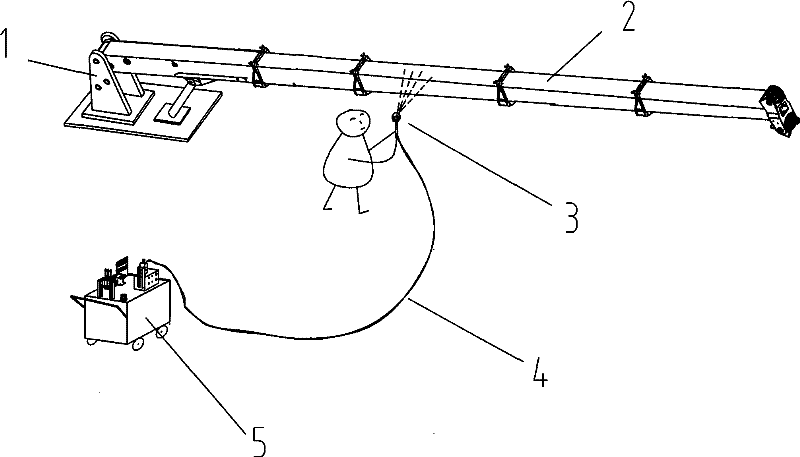

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] see figure 1 , the boom lubricating machine 5 equipment includes an electric oil pump, an electric lubricating pump, a spray gun 3, etc. First, the electric oil pump fills the clean molybdenum disulfide grease into the oil storage cylinder of the electric lubricating pump, and the penetration of the grease 265-385 (25°C, 150g) 1 / 10mm; the electric lubricating pump stirs and softens the lubricating grease delivered to the oil storage tank with blades, and then alternately presses the lubricating grease from the oil outlet through two sets of oil pressure pump cylinders. Send it out (nominal pressure: 38-42MPa), go through the high-pressure oil delivery hose (about 20 meters long) to the spray gun; When the high-pressure grease meets the compressed air at the nozzle of the injection valve, it is blown into tiny particles (atomization) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com