Novel rotary casing scraper

A scraper and rotary technology, which is applied in the field of new rotary casing scraper, can solve the problems of affecting the scraping operation, small scraping diameter, scraper loses scraping ability, etc., achieves stable scissor frame structure and increases scraping diameter , The effect of scraping efficiency is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

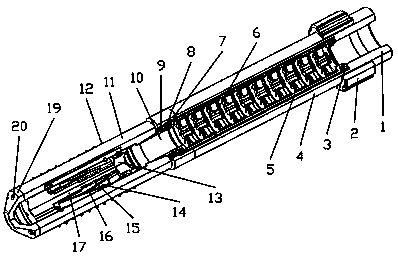

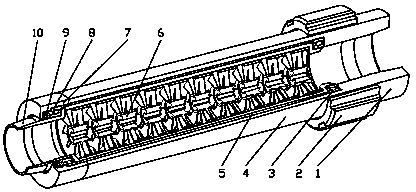

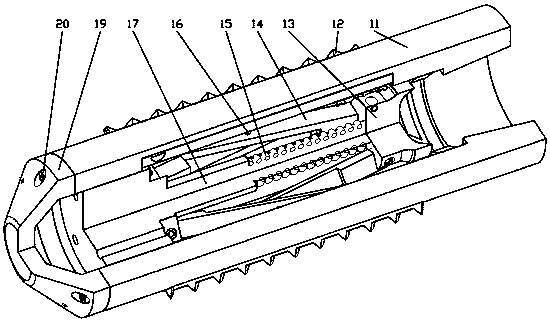

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is a novel rotary casing scraper, including a hydraulic drive assembly and a scraping tool assembly, the hydraulic drive assembly includes an upper joint 1, a centralizer 2, a radial thrust ball bearing 3, Scraper shell 4, scraper inner cylinder 5, turbine 6, seal seat 7, lower radial thrust ball bearing 8, dynamic sealing structure 9 and lower joint 10. The top of the scraper shell 4 is connected with the top of the upper joint 1 by a tapered thread to prevent tripping. The centralizer 2 is fixedly connected with the upper part of the scraper shell 4, so that the scraper is centered in the sleeve pipe, which is beneficial to the scraping work. The sealing seat 7 is fixedly connected with the bottom end of the scraper housing 4 , and its inner structure has a gradient for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com